Asphalt laying device based on municipal road engineering

A municipal road and laying device technology, applied in the field of machinery and equipment, can solve the problems of poor overall effect, bumpy vehicle driving, uneven pressing, etc., and achieve the effect of high construction efficiency, perfect overall function, and smooth pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

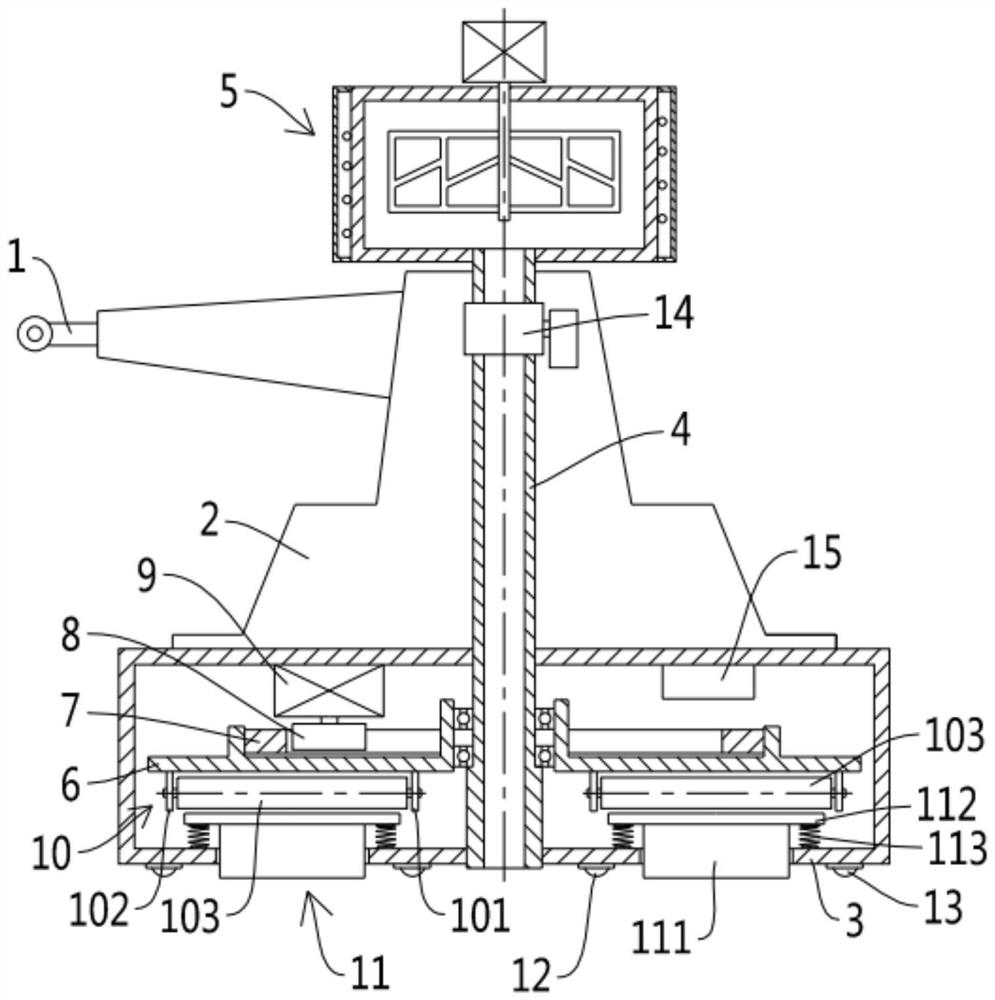

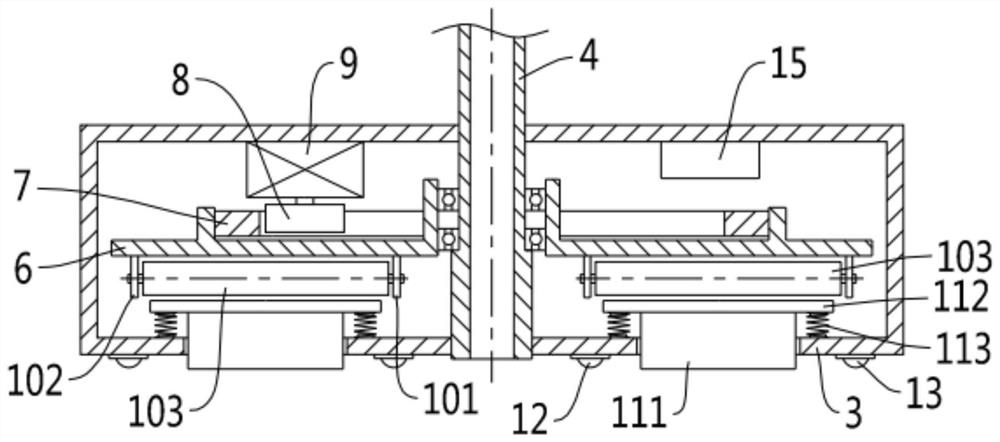

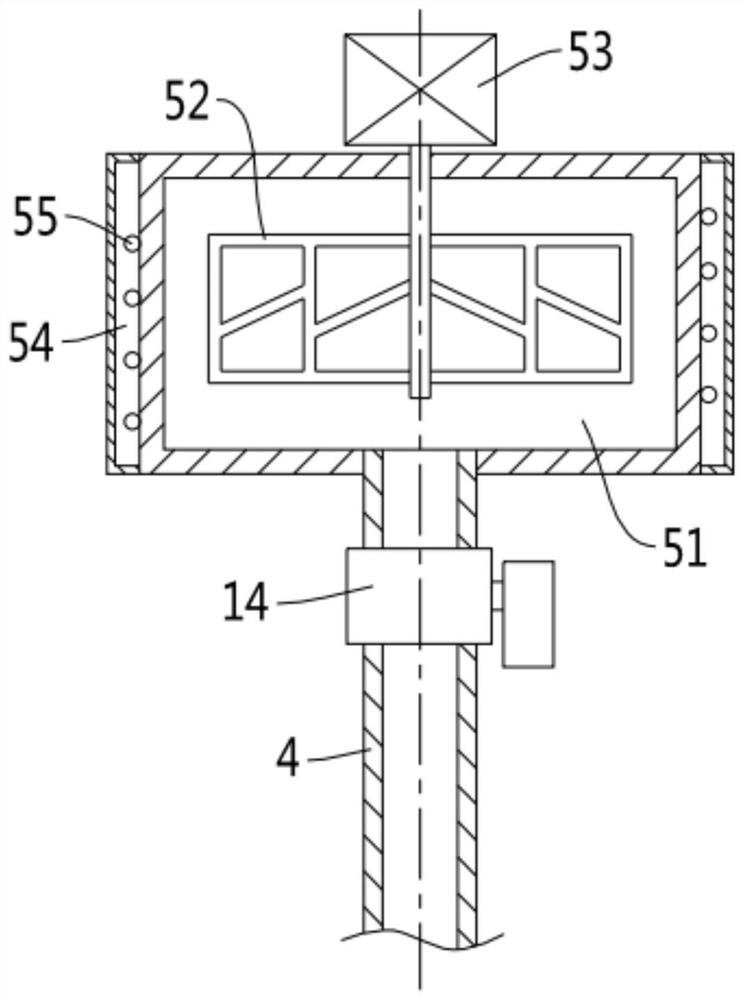

[0016] see Figures 1 to 3 As shown, a kind of asphalt laying device based on municipal road engineering involved in this embodiment includes a fuselage 2 provided with a push handle 1, and the bottom of the fuselage 2 has a planar bottom plate 3, on which the fuselage 2 A hollow feed shaft 4 extending vertically up and down is provided, the lower end of the hollow feed shaft 4 protrudes from the bottom plate 3, and the upper end is provided with a feed unit 5, the hollow feed shaft 4 is rotatably connected with a disc 6, The upper end surface of the disc 6 is provided with a ring gear 7 coaxial with the ring gear 7, and a gear 8 is meshed with the ring gear 7. The gear 8 is provided with a first motor 9 for controlling its rotation. The first motor 9 is located on the On the fuselage 2, the lower end surface of the disc 6 is provided with a plurality of pressure roller assemblies 10 arranged in an annular array at equal intervals around its axis. , an outer bracket 102 away ...

Embodiment 2

[0021] see Figures 1 to 3 As shown, a kind of asphalt laying device based on municipal road engineering involved in this embodiment, on the basis of Embodiment 1, it is further set that the side of the feed bin 51 is provided with a compartment surrounding it 54, the compartment 54 is provided with an electric heating wire 55 arranged on the feed bin 51 in the form of a spiral disk.

[0022] In this embodiment, through the arrangement of the compartment 54 and the electric heating wire 55, it is used to provide heat supply and heat preservation to the feed bin 51, so that the inside of the feed bin 51 is heated up, and the asphalt mixed with sand and gravel is prevented from being heated by the outside. Solidification occurs due to lower temperature, resulting in poor transportation.

Embodiment 3

[0024] see Figures 1 to 3 As shown, a kind of asphalt laying device based on municipal road engineering involved in this embodiment, on the basis of Embodiments 1 and 2, it is further set that, the hollow feed shaft 4 is connected in series with a close to the feed Solenoid valve 14 of unit 5.

[0025] In this embodiment, the solenoid valve 14 is used to control the on-off of the hollow feed shaft 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com