Steel belt type composite board unit

A composite board and steel strip technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of poor lamination flatness, complicated maintenance, large equipment volume, etc., and achieve smooth lamination and convenient maintenance. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

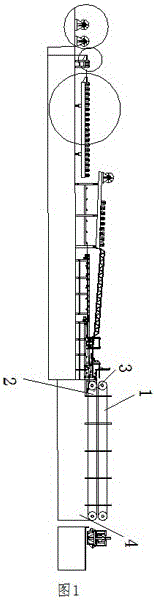

[0014] Such as figure 1 As shown, the specific embodiment adopts the following technical scheme: it comprises an upper steel belt 1, a lower steel belt 2, a drum 3 and a frame 4, the lower steel belt 2 is arranged below the upper steel belt 1, and the upper steel belt 1 and the lower steel belt The steel belts 2 are all connected to the rollers 3 on both sides, and the upper steel belt 1, the lower steel belt 2 and the rollers 3 are all fixedly arranged on the frame 4.

[0015] As a preference, there is a feed opening between the upper steel strip 1 and the lower steel strip 2 .

[0016] The working principle of this specific embodiment is: when working, the composite plate material enters between the upper steel belt 1 and the lower steel belt 2 from the left feed port, and then the roller 3 drives the upper steel belt 1 and the lower steel belt 2 to move, and the upper steel belt 1 and the lower steel belt 2 move. The steel belt 1 and the lower steel belt 2 drive the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com