Quick exhaust device for automobile oil way and use method of quick exhaust device

A technology of exhaust device and automobile oil circuit, which is applied in the direction of fuel injection device, electrical control, charging system, etc., which can solve the problems of long start-up time for the first time of a new car and affect the off-line of the new car, and achieve a reasonable and novel structural design and speed up the process of getting off the assembly line. Line beats, the effect of increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

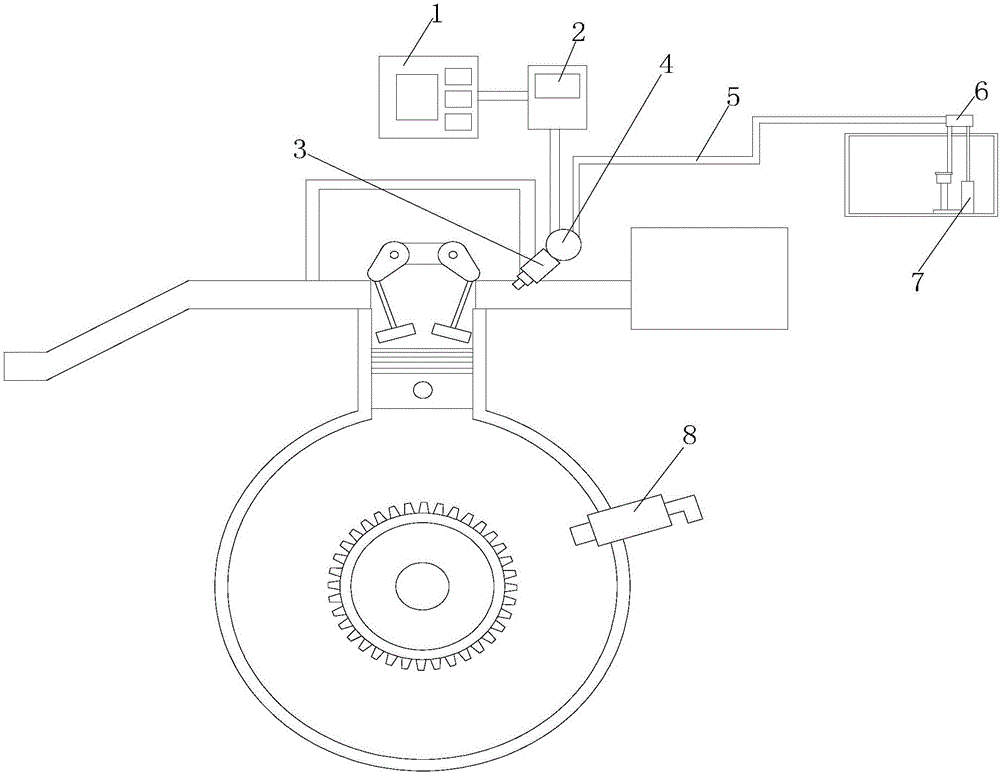

[0036] The invention relates to an automobile oil circuit quick exhaust device, comprising an engine, the engine is connected with the engine oil circuit, an instruction issuing device, the instruction issuing device is connected with an electronic control unit, the electronic control unit is connected with a fuel injector, and the fuel injector is connected with a The oil rail is arranged on the engine oil circuit; the engine is provided with a rotational speed sensor, and the rotational speed sensor is connected to the electronic control unit; the oil rail is connected to the fuel filter and the oil pump through the engine oil circuit.

[0037] A method for using a quick exhaust device for an automobile oil circuit is made by the following steps:

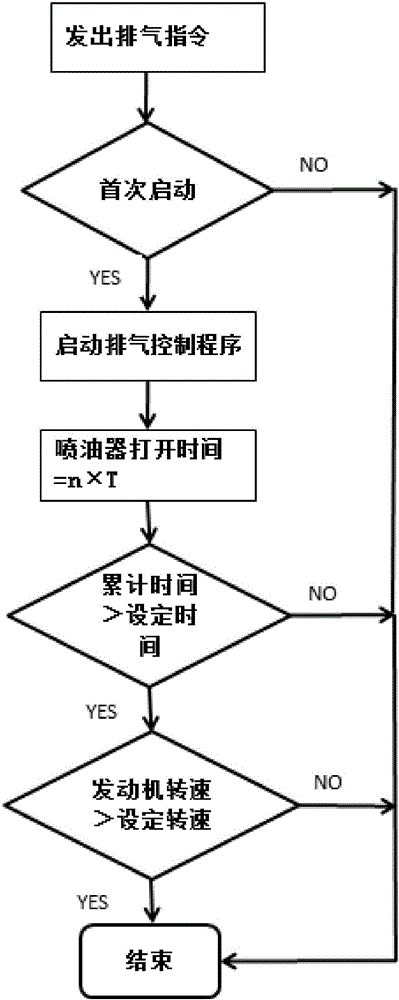

[0038] (1) The instruction issuing equipment on the engine production line issues the exhaust instruction. After receiving the exhaust instruction, the electronic control unit determines whether the vehicle is started for the first...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that: in step (4), it is determined whether the air in the engine oil circuit is emptied by detecting whether the accumulated exhaust time is greater than the set exhaust time.

[0051] The calculation formula of the exhaust cumulative time is:

[0052] Exhaust cumulative time t=V 总 / (Q×n×T÷1000×m)

[0053] where: V 总 =V 滤清器 +V 管 +V 油轨 +V 喷油器

[0054] Q--fuel injection volume per unit time, unit ml / s;

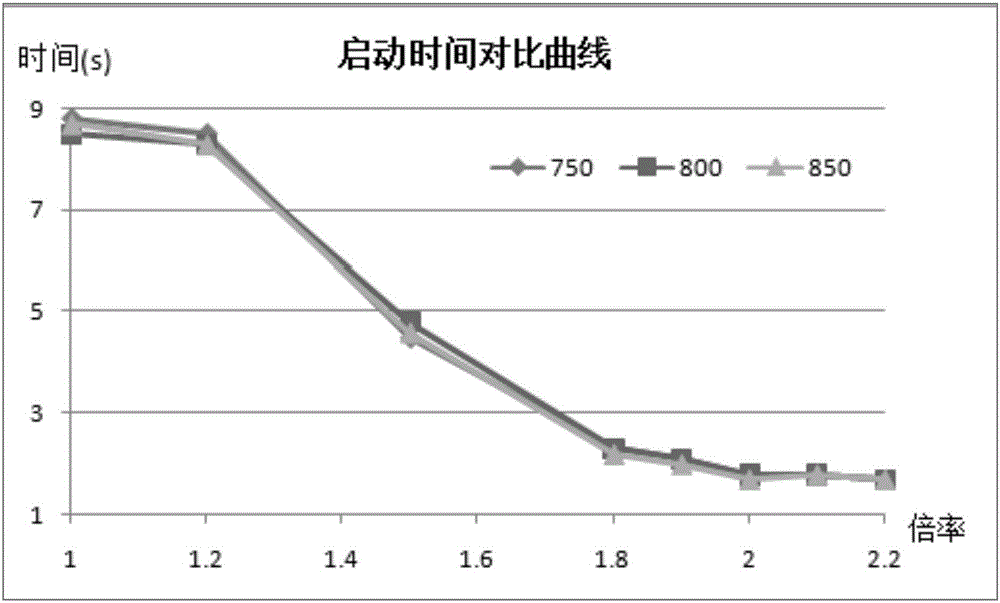

[0055] n--Injector opening time magnification (for fast exhaust, n>1), hereinafter referred to as "magnification"

[0056] T--Injector single opening time, unit: ms, this parameter is a parameter in the normal fuel injection program, and is related to the engine water temperature;

[0057] m--the total opening times of the injectors of each cylinder;

[0058] V is the total volume of the engine oil circuit cavity;

[0059] V filter is the volume of the inner cavity of the filter;

[0060] The V tube is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com