Corn double-ridge film mulching seeding combined planting machine

A combined working machine and mulching technology, applied in fertilizers, seeding equipment, plant protection covers, etc., can solve the problem of reducing the quality of sowing operations, failing to meet the agronomic requirements of soil thickness and sealing degree, and poor quality and effect of self-flow mulching. problems, to achieve the effect of good seeding operation quality, high operation efficiency and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

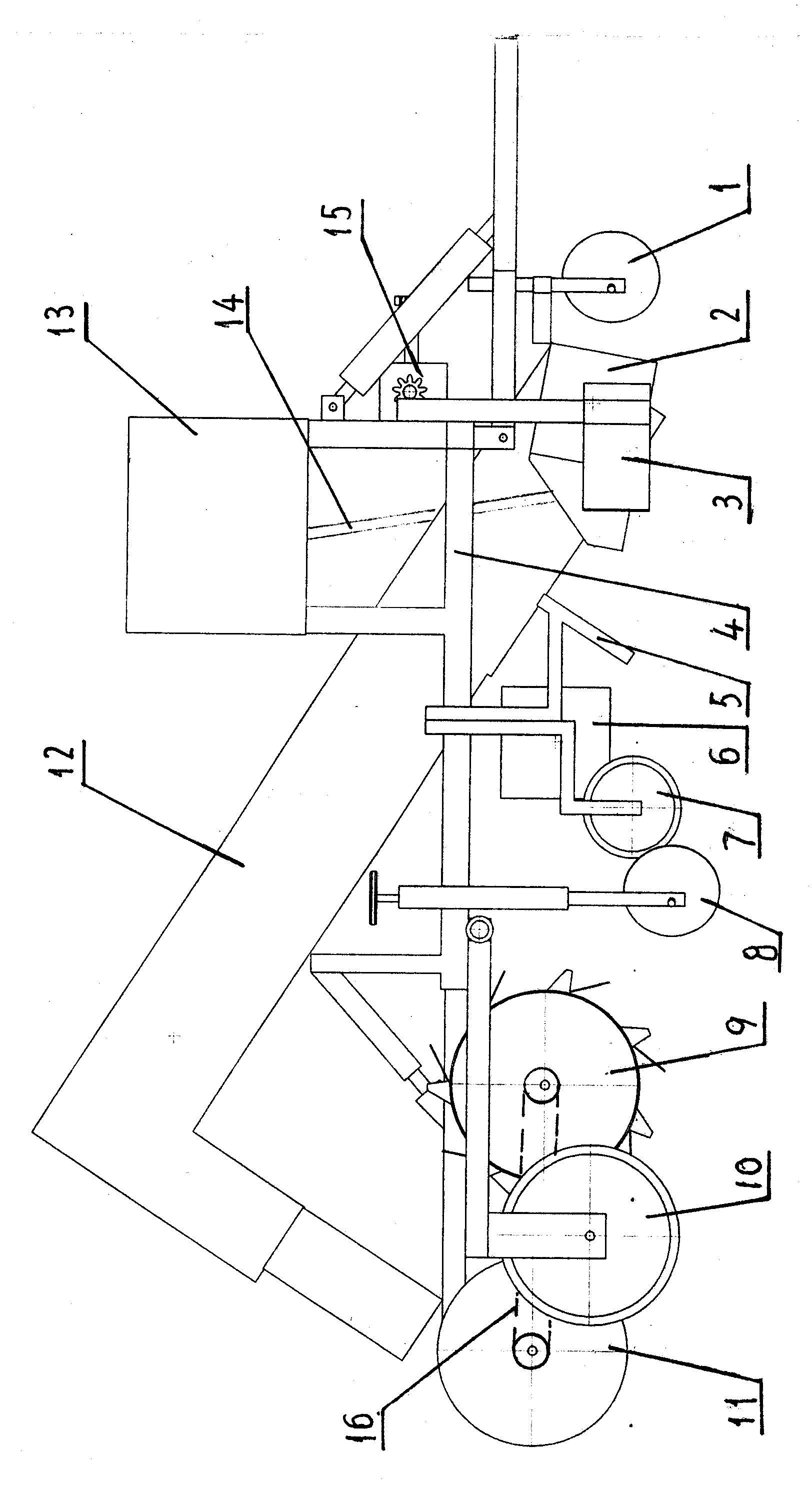

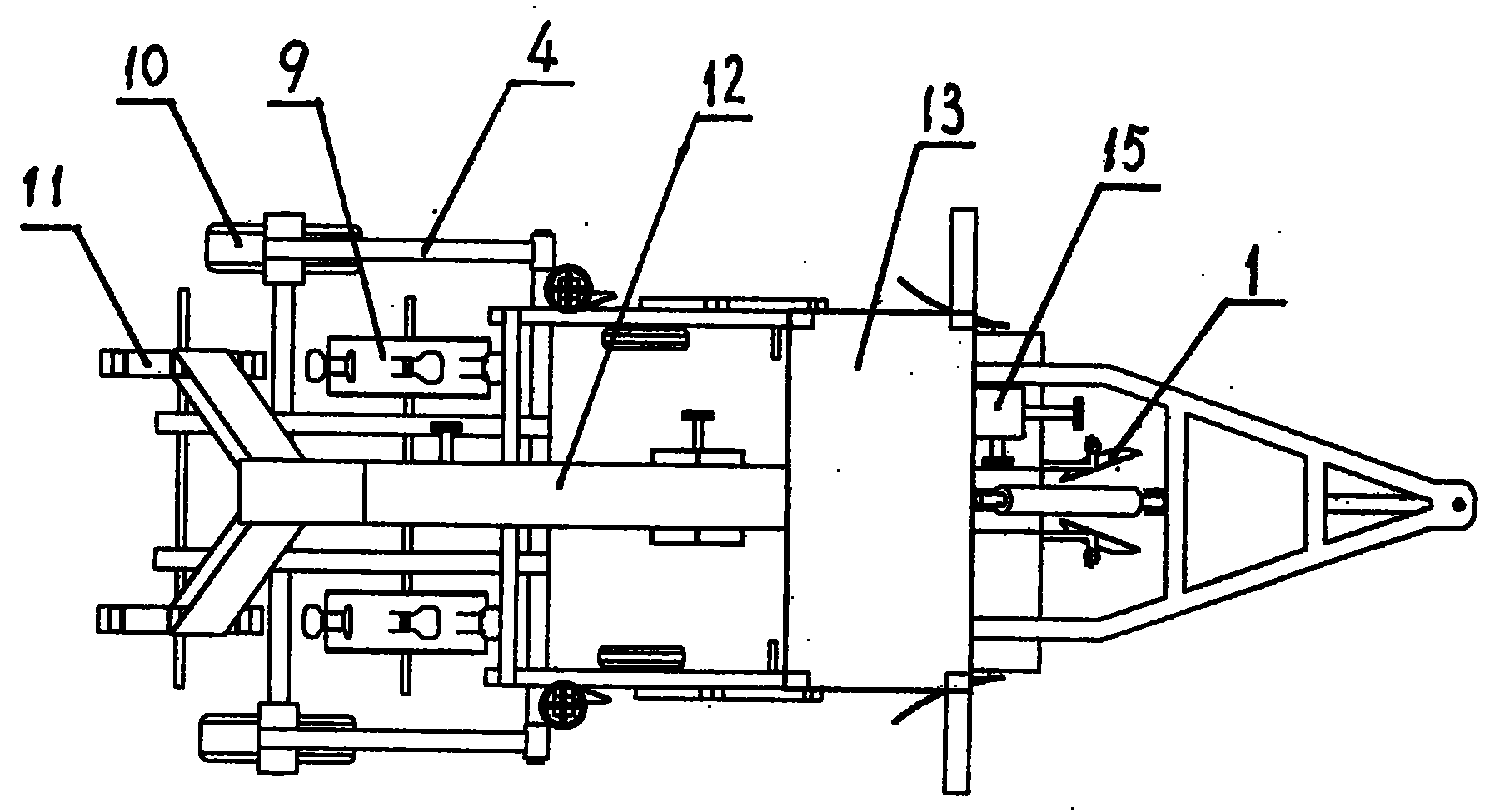

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A corn double-ridge film-covered sowing combined operation machine includes a frame 4 and a ridge body shaper 2 equipped on the frame 4, a film edge ditcher 3, a plastic film roller frame 5, a soil covering device 6 between the plastic film double-ridges, Membrane edge press wheel 7, membrane edge soil covering device 8, duckbill type sowing drum 9, ground wheel 10 and fertilizer box 13, fertilizer delivery pipe 14 communicates fertilizer box 13 with ridge shaper 2, respectively on frame 4 Equipped with a soil collector 1, a chain rake type soil conveying assembly 12, a groove type soil covering roller 11 and a power transmission box 15, the soil collector 1 is located in front of the ridge shaper 2, and the front end of the chain rake soil conveying assembly 12 The soil inlet is located at the rear side of the soil collector 1, and the power transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com