Filling machine for cosmetics

A cosmetics and filling technology, which is applied in the cleaning of filling devices, packaging, bottle filling, etc., can solve the problems of large floor area, complex structure, labor-intensive, etc., and achieve the effect of low cost, small volume, and novel and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

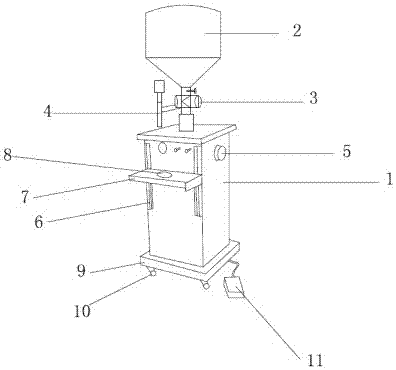

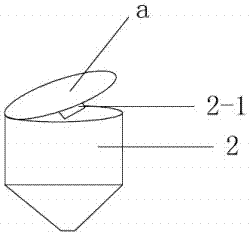

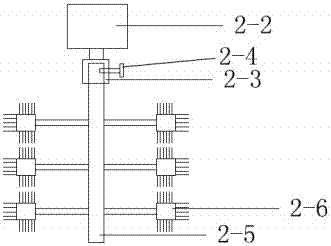

[0012] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: it includes a body 1, a feed hopper 2, a pneumatic valve 3, a pneumatic discharge port 4, a filling volume adjustment knob 5, a slide rail 6, a filling bottle placement plate 7, Place groove 8, base 9, roller 10 and foot switch 11, the bottom of body 1 is fixed on base 9, and several rollers 10 are installed on the bottom of base 9, feed hopper 2 is connected with the top of body 1, body 1 There is a filling volume adjustment knob 5 on the side, a pneumatic valve 3 is installed at the bottom of the feed hopper 2, and the lower end of the feed hopper 2 is connected to the pneumatic discharge port 4, and a filling valve is installed below the pneumatic discharge port 4. The bottle placement plate 7 and the filling bottle placement plate 7 are slidably connected to the slide rail 6, and the slide rail 6 is arranged on the front side of the body 1, and the filling bottle placeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com