Dispensing and laminating device for assembling LED lamp

A technology of pressing device and LED light bar is applied in the direction of lighting device, light source, semiconductor device of light-emitting element, etc., which can solve the problems of high labor intensity and reduce assembly efficiency, and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

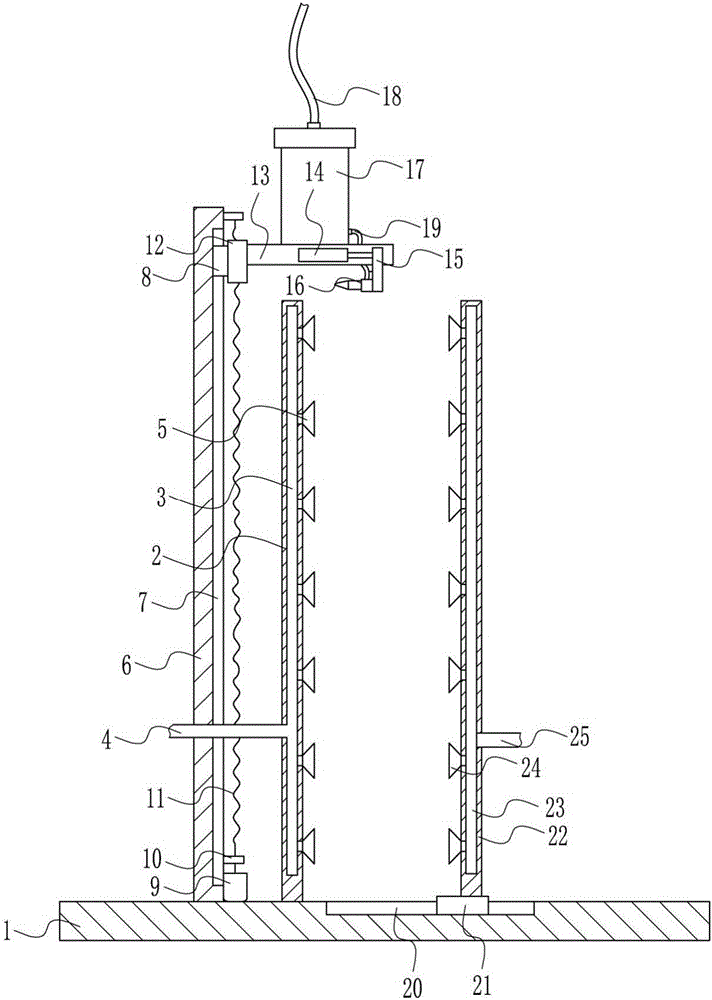

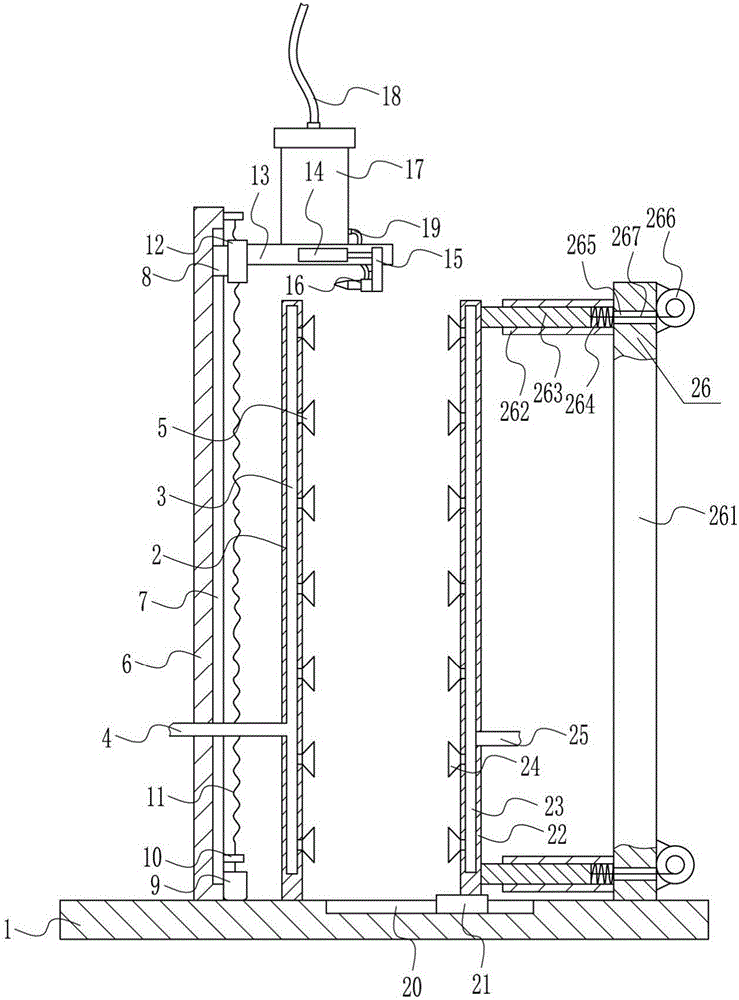

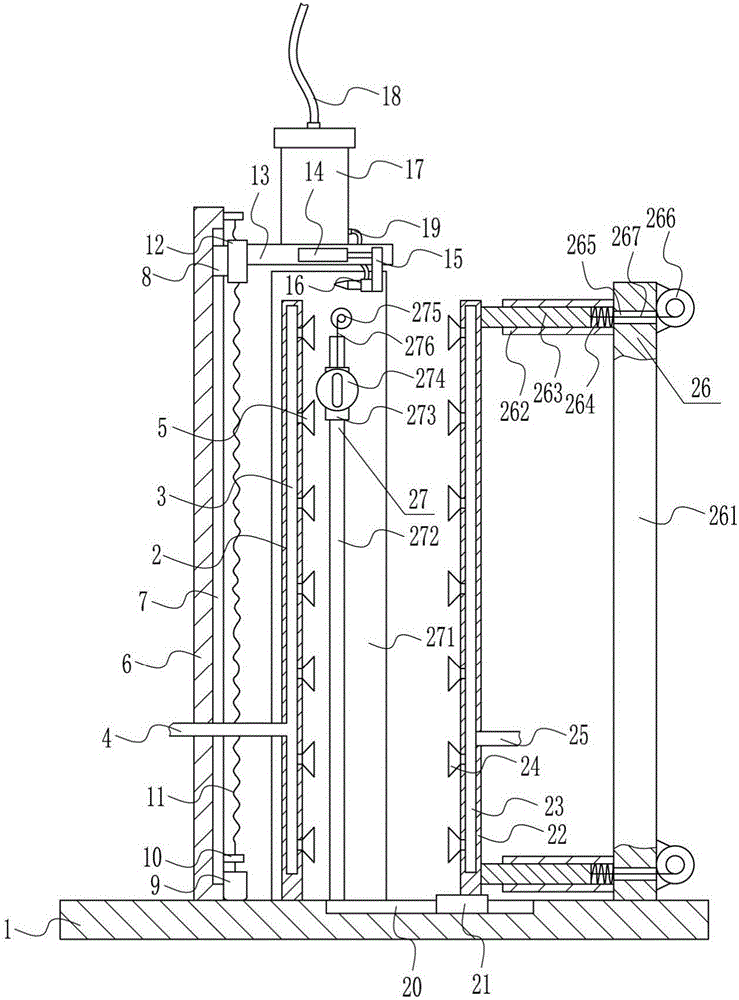

[0033] A dispensing and pressing device for LED light bar assembly, such as Figure 1-5 As shown, it includes a bottom plate 1, a fixed plate 2, a first air pipe 4, a first vacuum chuck 5, a riser 6, a first slider 8, a first motor 9, a bearing seat 10, a screw rod 11, a nut 12, the first A mounting plate 13, telescopic device 14, pole 15, glue outlet head 16, glue tank 17, air inlet pipe 18, glue outlet pipe 19, second slider 21, movable plate 22, second vacuum suction cup 24 and second air pipe 25 , the top of the bottom plate 1 is vertically connected with a fixed plate 2 by means of bolt connection, a first cavity 3 is opened in the fixed plate 2, a first air pipe 4 is connected to the left side of the fixed plate 2, and the first air pipe 4 leads into the first air pipe 4. In a cavity 3, a plurality of first vacuum suction cups 5 are evenly spaced from top to bottom on the right side of the fixed plate 2, and the top of the bottom plate 1 on the left side of the fixed pla...

Embodiment 2

[0035] A dispensing and pressing device for LED light bar assembly, such as Figure 1-5 As shown, it includes a bottom plate 1, a fixed plate 2, a first air pipe 4, a first vacuum chuck 5, a riser 6, a first slider 8, a first motor 9, a bearing seat 10, a screw rod 11, a nut 12, the first A mounting plate 13, telescopic device 14, pole 15, glue outlet head 16, glue tank 17, air inlet pipe 18, glue outlet pipe 19, second slider 21, movable plate 22, second vacuum suction cup 24 and second air pipe 25 , the top of the bottom plate 1 is vertically connected with a fixed plate 2 by means of bolt connection, a first cavity 3 is opened in the fixed plate 2, a first air pipe 4 is connected to the left side of the fixed plate 2, and the first air pipe 4 leads into the first air pipe 4. In a cavity 3, a plurality of first vacuum suction cups 5 are evenly spaced from top to bottom on the right side of the fixed plate 2, and the top of the bottom plate 1 on the left side of the fixed pla...

Embodiment 3

[0038] A dispensing and pressing device for LED light bar assembly, such as Figure 1-5 As shown, it includes a bottom plate 1, a fixed plate 2, a first air pipe 4, a first vacuum chuck 5, a riser 6, a first slider 8, a first motor 9, a bearing seat 10, a screw rod 11, a nut 12, the first A mounting plate 13, telescopic device 14, pole 15, glue outlet head 16, glue tank 17, air inlet pipe 18, glue outlet pipe 19, second slider 21, movable plate 22, second vacuum suction cup 24 and second air pipe 25 , the top of the bottom plate 1 is vertically connected with a fixed plate 2 by means of bolt connection, a first cavity 3 is opened in the fixed plate 2, a first air pipe 4 is connected to the left side of the fixed plate 2, and the first air pipe 4 leads into the first air pipe 4. In a cavity 3, a plurality of first vacuum suction cups 5 are evenly spaced from top to bottom on the right side of the fixed plate 2, and the top of the bottom plate 1 on the left side of the fixed pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com