Motor sealing performance testing device and testing method

A testing device and sealing technology, which are applied in the direction of using liquid/vacuum for liquid tightness measurement, and by measuring the acceleration and deceleration rate of fluid, etc., to achieve the effects of improving test efficiency, ensuring air pressure, and reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

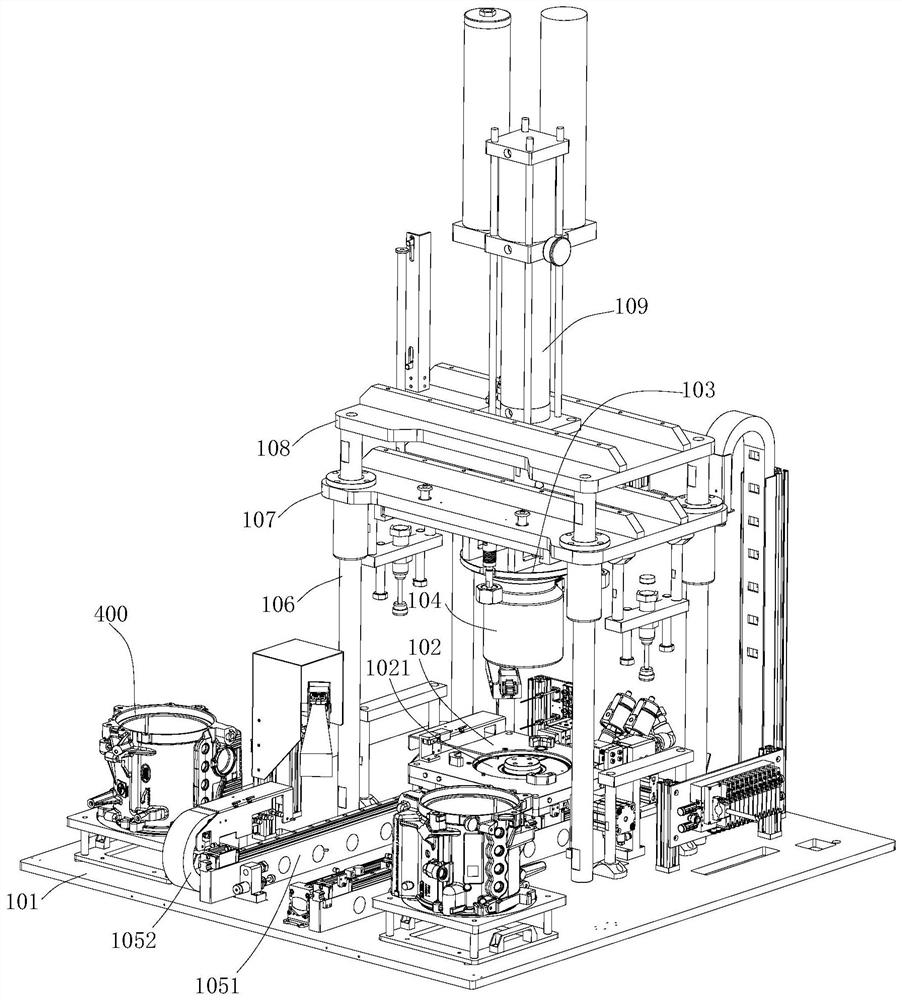

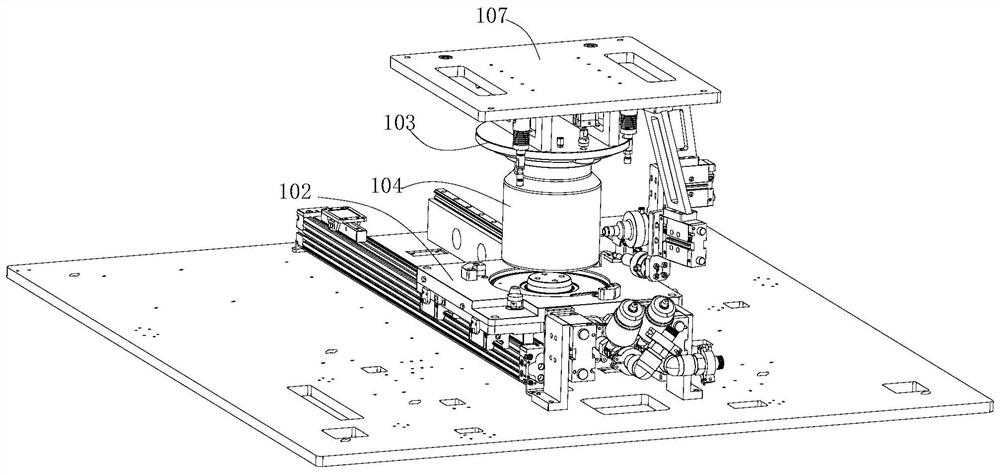

[0055] Please refer to Figure 1-12 , a kind of motor tightness testing device, comprises frame, is provided with horizontal workbench 101 on the frame, the length direction of workbench 101 is the X-axis direction, the width direction of workbench Y-axis direction, the height direction of workbench is Z-axis direction;

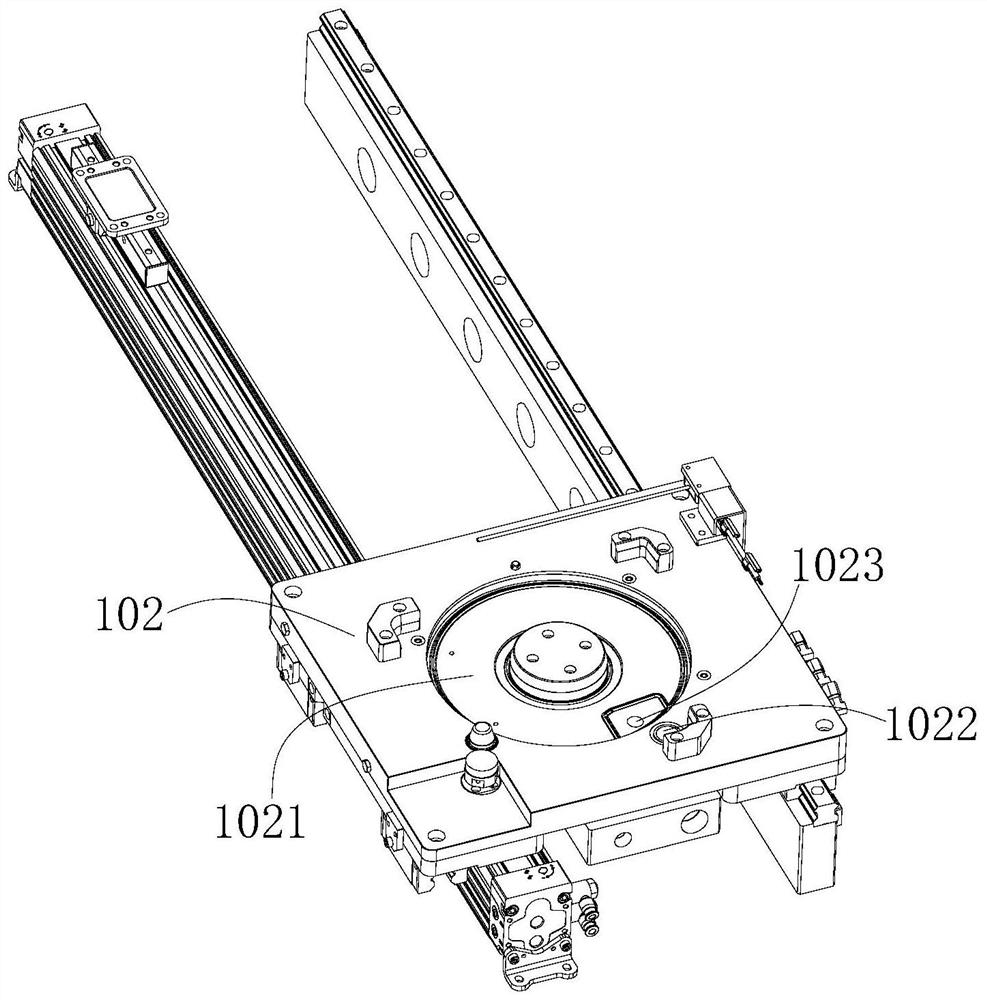

[0056] The workbench 101 is provided with a motor tray 102, a Z-axis lifting mechanism and a volume filling block 104;

[0057] The top surface of the motor tray 102 is provided with a receiving groove 1021 for placing the motor housing 400;

[0058] The Z-axis lifting mechanism includes a blocking plate 103 for sealing the top opening of the motor housing and a Z-axis driving device for driving the blocking plate 103 to move along the Z-axis direction; the Z-axis driving device can specifically be an air cylinder.

[0059] The volume filling block 104 is arranged on the bottom surface of the blocking plate 103; or, the volume filling block is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com