Environment protecting paper

A technology of environmentally friendly paper and composition, which is applied in the field of environmentally friendly paper and its manufacturing, and can solve the problems of no tearing, no oxidative decomposition, poor folding properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

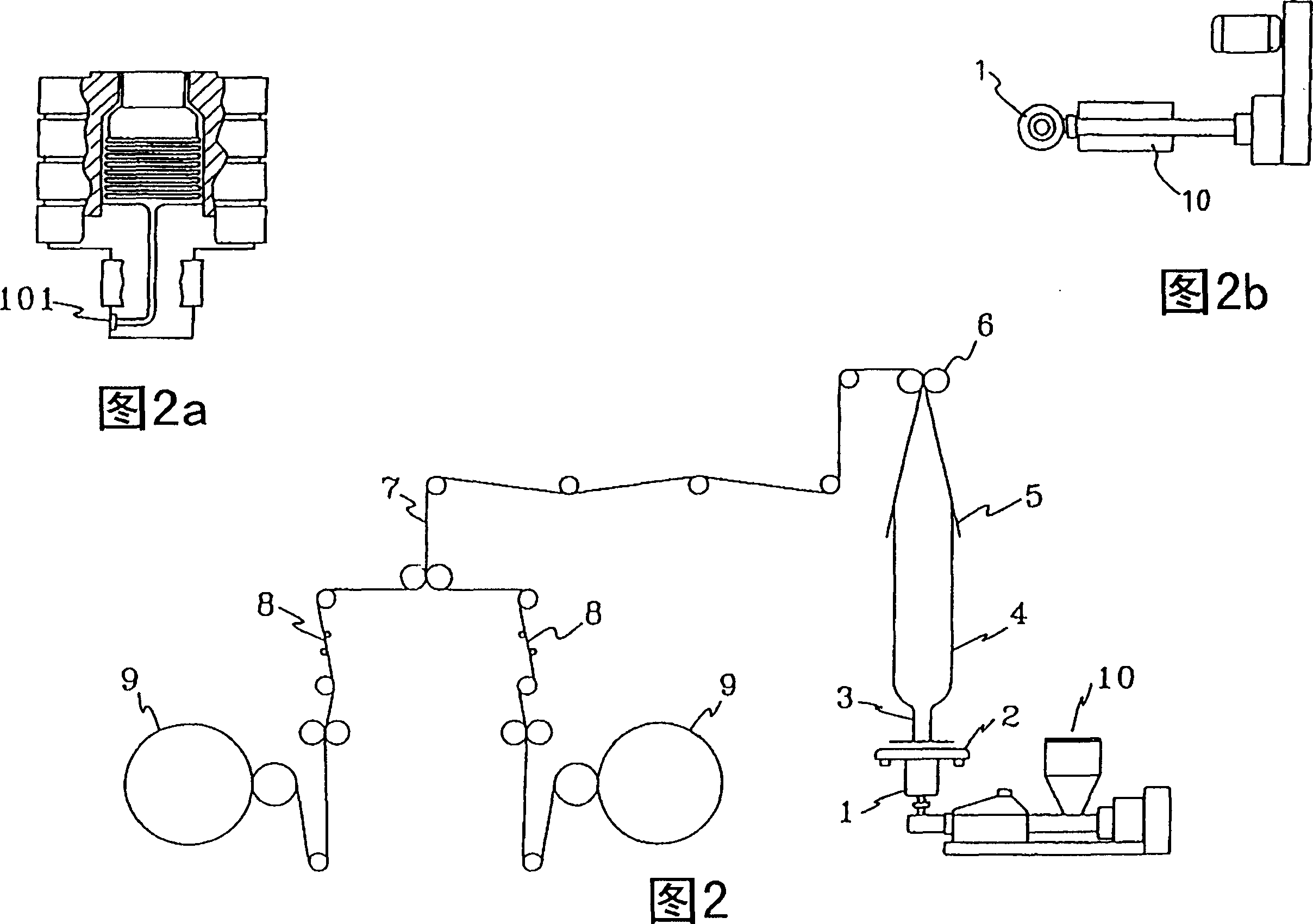

Method used

Image

Examples

Embodiment 1

[0092] Embodiment 1: the manufacture of single-layer environmental protection paper

[0093] 60% by weight of natural inorganic mineral powder (wherein calcium carbonate accounts for 28% by weight, titanium dioxide accounts for 7% by weight, diatomaceous earth accounts for 25% by weight); 38% by weight of polyethylene (wherein high density polyethylene accounts for 20% by weight, low Density polyethylene accounts for 10% by weight, linear low density polyethylene accounts for 8% by weight) and 2% by weight of additives (0.8% by weight of β-(3,4-epoxycyclohexyl) ethyl trimethoxysilane, 0.4% by weight % N-oleyl palmitic acid amide and 0.8% by weight N,N-bis(2-hydroxyethyl)stearamide). The above material ingredients add up to 100% by weight. After mixing, extrusion, kneading and polymerization, they are made into granules, put into paper film manufacturing machinery, and production adjustments are made according to the requirements of product thickness to produce single-layer env...

Embodiment 2

[0094] Embodiment 2: the manufacture of single-layer environmental protection paper

[0095] 70% by weight of natural inorganic mineral powder (wherein calcium carbonate accounts for 35% by weight, titanium dioxide accounts for 6% by weight, diatomaceous earth accounts for 24% by weight, clay accounts for 5% by weight); 28% by weight polyethylene (wherein high density polyethylene accounts for 5% by weight); 20% by weight, linear low density polyethylene accounts for 8% by weight) and 2% by weight of additives (0.8% by weight (3,4-epoxycyclohexyl) ethyl trimethoxysilane, 0.4% by weight N-oleyl palm acid amide and 0.8% by weight N,N-bis(2-hydroxyethyl)stearamide). The above material ingredients add up to 100% by weight. After mixing, extrusion, kneading and polymerization, they are made into granules, put into paper film manufacturing machinery, and production adjustments are made according to the requirements of product thickness to produce 73 micron and 82 micron environmenta...

Embodiment 3

[0096] Embodiment 3: the manufacture of single-layer environmental protection paper:

[0097] 80% by weight of natural inorganic mineral powder (wherein calcium carbonate accounts for 35% by weight, titanium dioxide accounts for 5% by weight, diatomaceous earth accounts for 35% by weight, and talcum powder accounts for 5% by weight); 18% by weight of polyethylene (high-density polyethylene) And 2% by weight of additives (0.8% by weight of β-(3,4-epoxycyclohexyl) ethyl trimethoxysilane, 0.4% by weight of N-oleyl palmitic acid amide and 0.8% by weight of N-bis(2- hydroxyethyl) stearamide). The above material ingredients add up to 100% by weight. After mixing, extrusion, kneading and polymerization, they are made into granules, put into paper film manufacturing machinery, and production adjustments are made according to the requirements of product thickness to produce environmentally friendly paper film substrates of 102 microns and 116 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com