A kind of outer protective layer sheet production device

A technology of production equipment and outer protective layer, which is applied in the field of outer protective layer sheet production equipment, and can solve problems such as pipelines are easy to be corroded, hidden dangers, and exist safety

Active Publication Date: 2018-11-16

江苏玖尚新材料有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]

Pipelines are easily corroded in underwater or underground environments, and are generally protected by coating anti-corrosion coatings, but this method has a short protection period, and there are still potential safety hazards in long-term use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0067] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

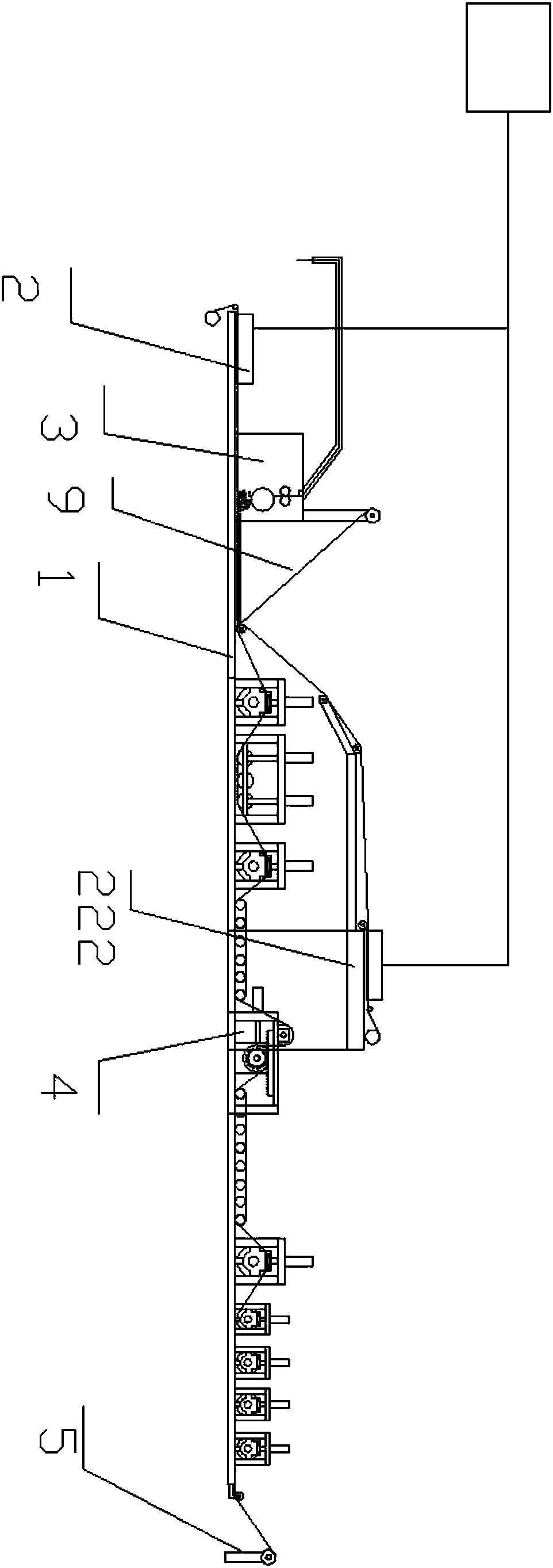

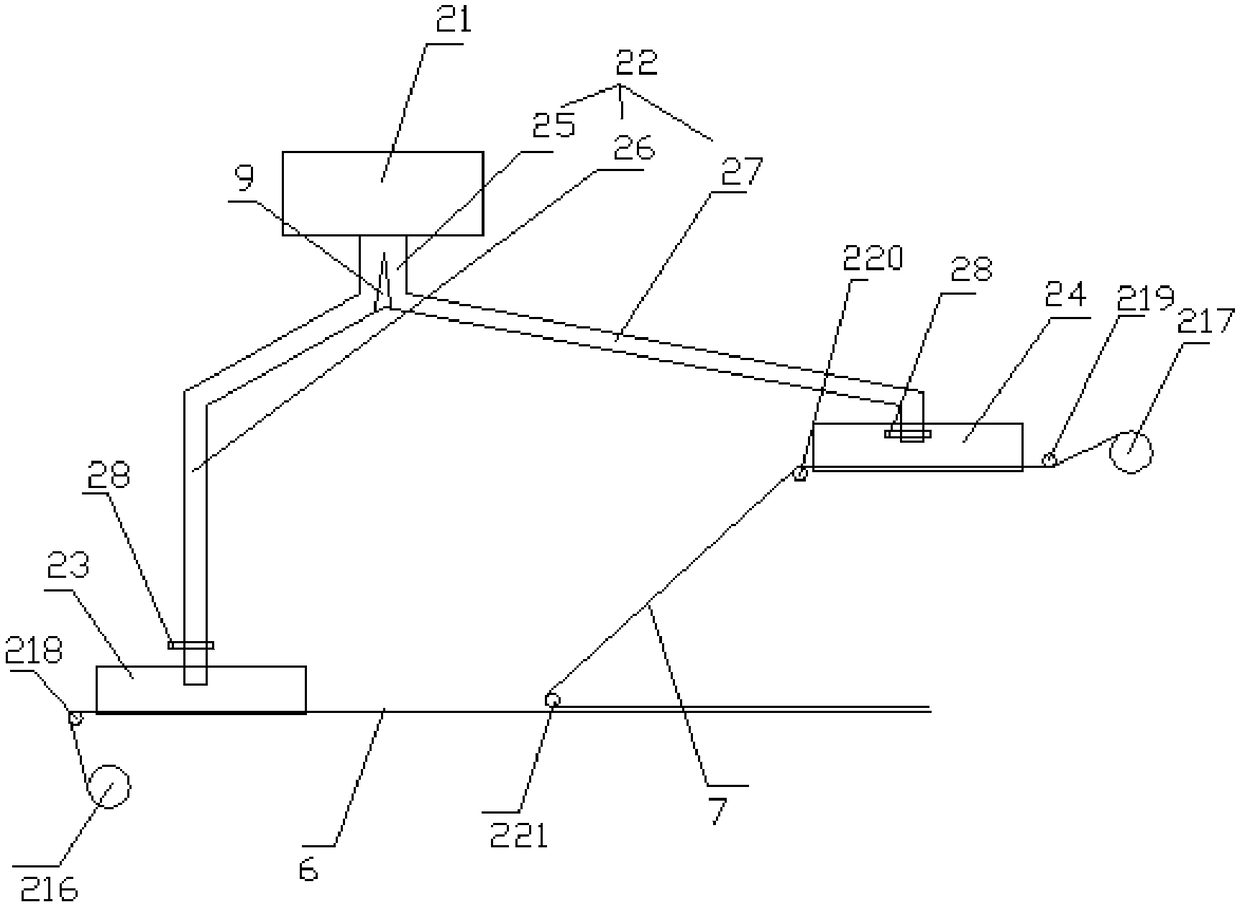

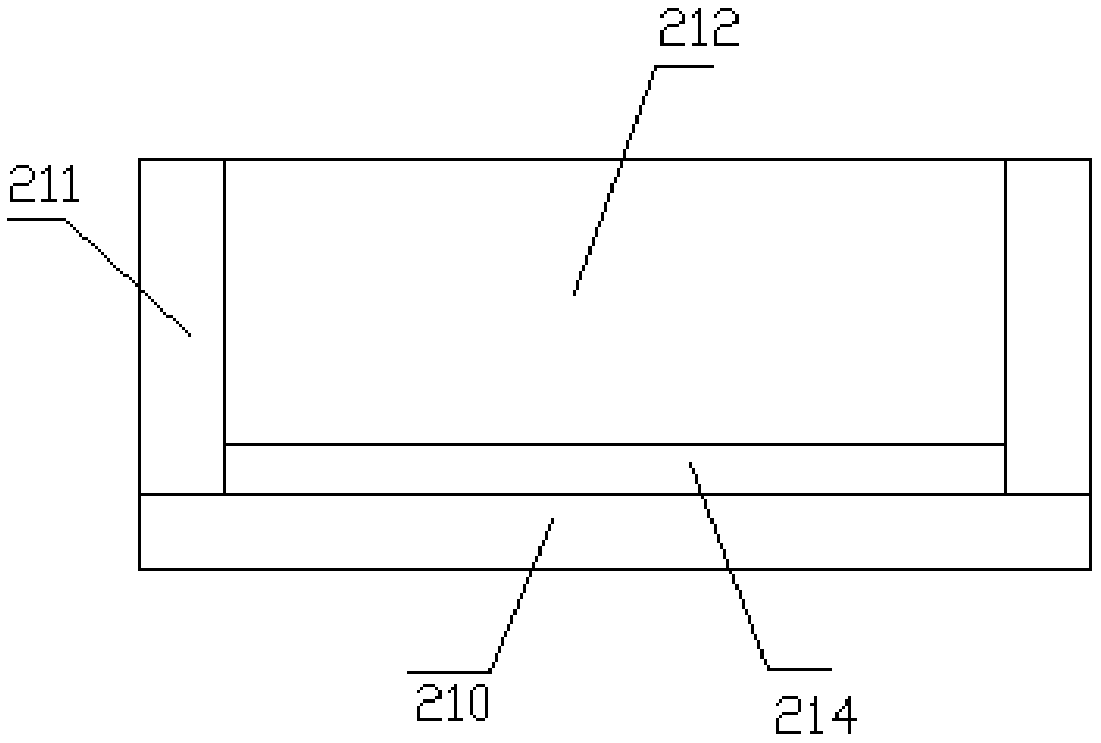

The invention relates to a production device for an outer protective layer sheet. The production device comprises a base; a base material feeding mechanism, a glass fiber feeding mechanism and a rolling mechanism are arranged on the base; a take-up mechanism is arranged at one side of the base; the base material feeding mechanism is used for separately forming an outer epoxy vinyl ester base layer and an inner epoxy vinyl ester base layer on an upper bearing film and a lower bearing film; the glass fiber feeding mechanism is used for adding a glass fiber reinforcing layer and a glass fiber loop bonding felt between the outer epoxy vinyl ester base layer and the inner epoxy vinyl ester base layer; the rolling mechanism is used for pressing and forming the upper bearing film, the outer epoxy vinyl ester base layer, the glass fiber reinforcing layer, the glass fiber loop bonding felt, the inner epoxy vinyl base layer and the lower bearing film; and the take-up mechanism is used for collecting and rolling a pressed and formed outer protective sheet. The production device is automatic in operation, improves working efficiency and product quality, and improves flatness of products.

Description

technical field [0001] The invention relates to a production device, in particular to a production device for an outer protective layer sheet. Background technique [0002] Pipeline crossing project is a pipeline project in which transportation pipelines are laid underwater or underground through rivers, lakes, railways, highways and other areas. [0003] Pipelines are easily corroded in underwater or underground environments, and are generally protected by coating anti-corrosion coatings. However, this method has a short protection period and still poses safety hazards when used for a long time. [0004] The applicant has developed a six-layer structure of the outer protective layer sheet, the sheet from bottom to top is "upper bearing film, outer epoxy vinyl ester base layer, glass fiber reinforced layer, glass fiber stitched mat , Inner epoxy vinyl ester base layer and lower bearing film", this kind of sheet has light weight, high tensile strength and weather resistance,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B32B37/00B32B37/12

CPCB32B37/0053B32B37/12

Inventor 佘德云

Owner 江苏玖尚新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com