PCB soldering flake pulse hot press

A technology for PCB circuit boards and heat presses, which is applied to printed circuits, printed circuit manufacturing, and printed circuit assembly of electrical components, etc. It can solve problems such as loose joints, unevenness, and influence on the welding of electronic components, and achieves easy operation. , simple structure, and the effect of improving welding yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

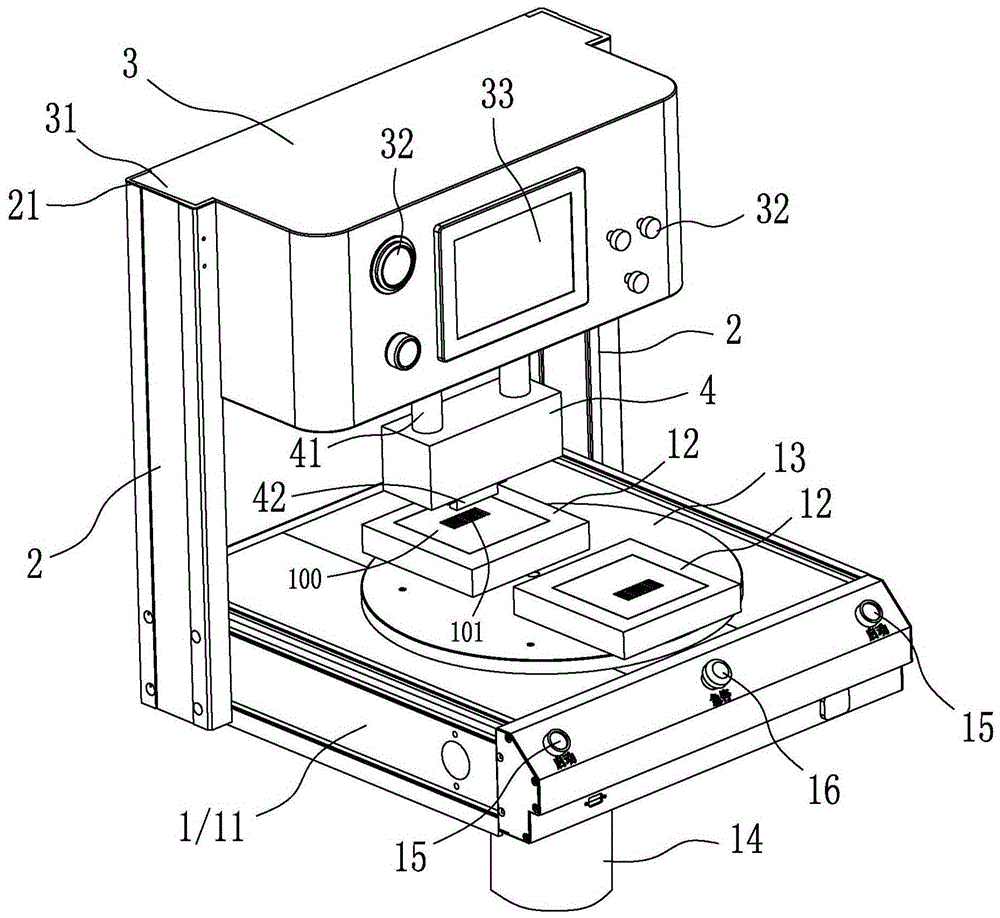

[0015] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, the present invention is a pulse heat press for PCB circuit board solder tabs, including a machine base 1, two stand 2, a machine head 3 and a heat pressing head 4; the machine base 1 is provided with an operating platform 11 , the middle part above the operating platform 11 is equipped with a circuit board tray 12 for placing the PCB circuit board 100; Machine head 3; described hot pressing head 4 is installed on the lower end of described machine head 3, and the lower end of hot pressing head 4 is corresponding to described circuit board tray 12; Described machine head 3 is provided with a cylinder (in the figure not shown), the telescopic rod of the cylinder is connected to the thermal head 4 to drive the thermal head 4 to press down or rise in a pulsed manner; the thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com