Oil drill rod circumferential surface rust removing device

An oil drill pipe and circumferential surface technology, which is applied to grinding drive devices, machine tools designed for grinding workpiece rotating surfaces, and grinding machines, etc., can solve the problems of low efficiency, inability to grind, and high operating intensity of construction personnel, and achieve high efficiency. High and fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

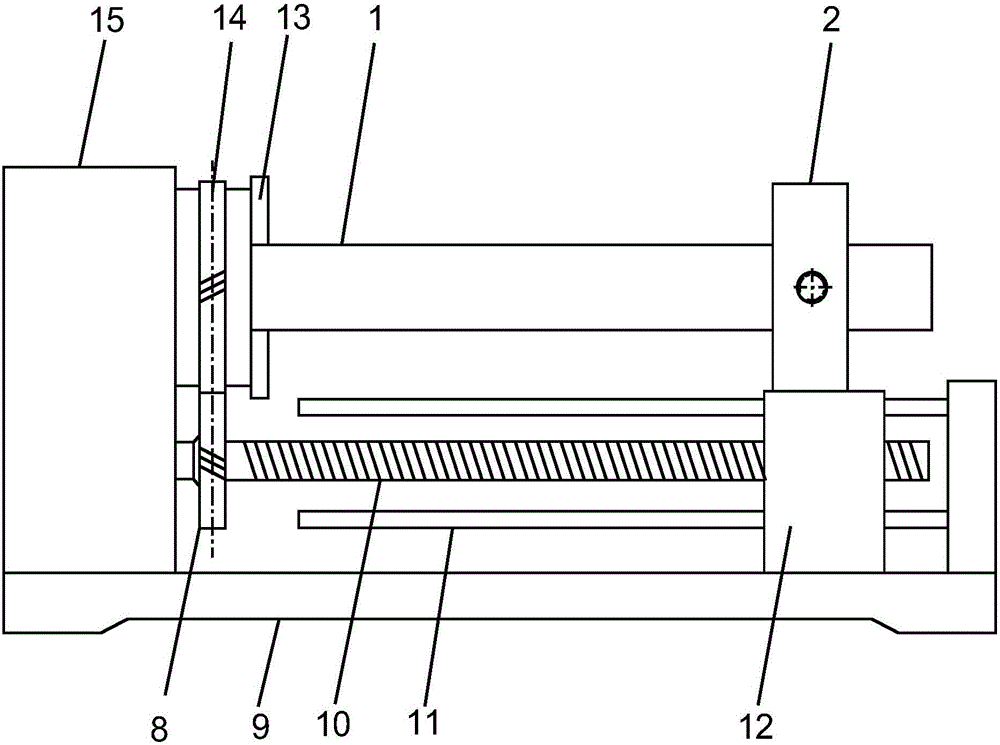

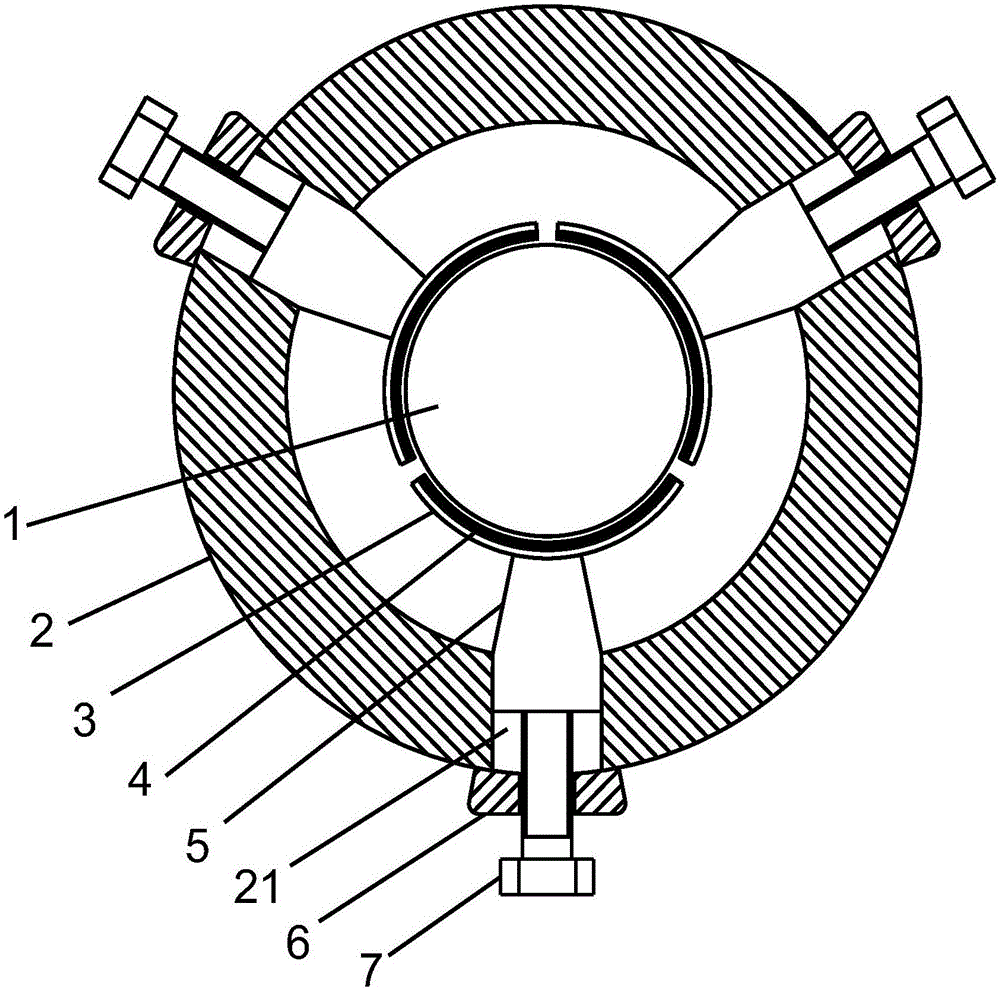

[0018] see Figure 1~2 , in the embodiment of the present invention, a kind of oil drill pipe circumferential surface derusting device comprises: frame 9, power box 15, three-jaw chuck 13 and annular plate 2, described power box 15 and existing common lathe The power box is similar, and includes a power assembly composed of a driving device (motor) and a speed change mechanism. The three-jaw chuck 13 is connected to the driving device, and the annular plate 2 is a ring-shaped plate, and a holding plate is arranged inside it. 3. The holding plate 3 is three arc-shaped plates formed by dividing the entire annular plate into three equal parts. The inner surface of the holding plate 3 is provided with sandpaper 4, and the holding plate 3 is wrapped on the circumferential surface of the drill pipe 1. The middle part of the outer surface of the plate 3 is welded to connect the slide block 5, and three equally divided cylindrical holes 21 are arranged on the annular plate 2, and the ...

Embodiment 2

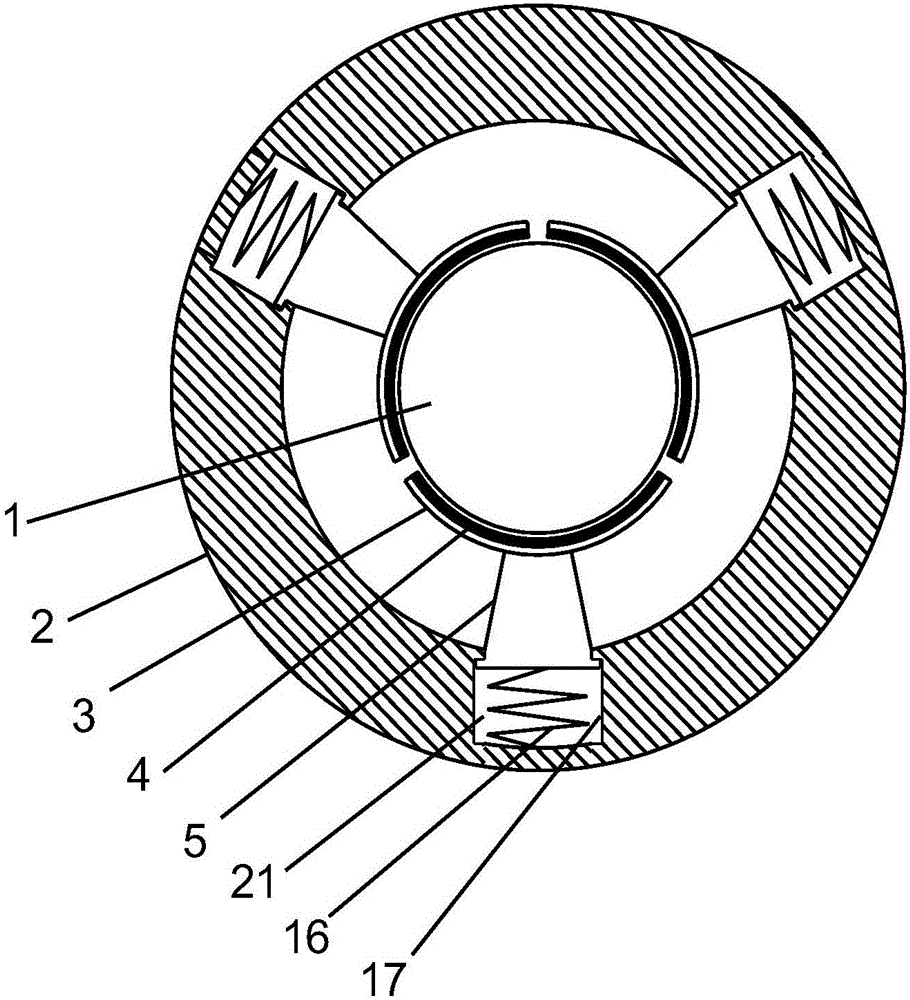

[0020] see Figure 3-4 , the present invention provides another embodiment, the bolt 7 and boss 6 in Embodiment 1 are replaced, and a compression spring 16 is set in the cylindrical hole 21. When the drill pipe 1 is installed, the compression spring 16 is compressed, and the The elastic force of the spring 16 makes the grinding sandpaper 4 close to the surface of the drill rod 1, a limit groove 17 is set in the cylindrical hole 21, a protrusion is arranged on the slider 5 and is located in the limit groove 21, and the limit groove 17 limits the movement of the slider 5. Move to prevent the slide block 5 from breaking away from the cylindrical hole 21; the expansion plate 18 is also fixed and inclined on the holding plate 3, and the three expansion plates 18 can encircle a trumpet-shaped variable diameter hole. When the drill pipe 1 is installed, from the expansion The large round hole end of the diameter plate 18 penetrates, and the drill pipe 1 contacts with the expansion pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com