Roadway tunneling support robot, matching support and support method

A robot and roadway technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems that affect the construction speed, can not be arched, no tunneling, etc., to improve safety and reliability, reduce contact pressure, and increase tunneling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

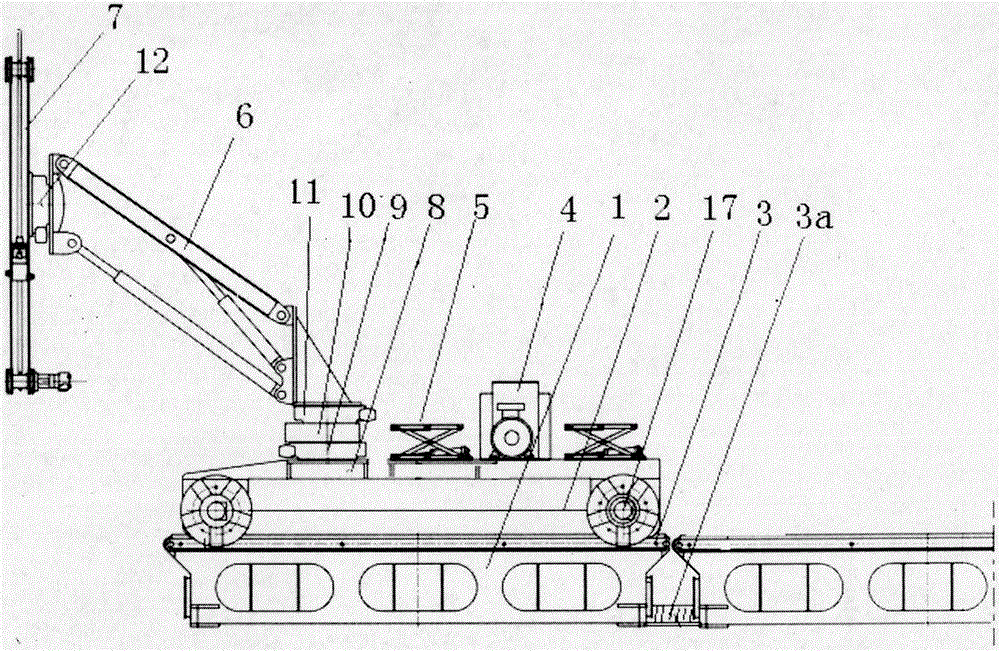

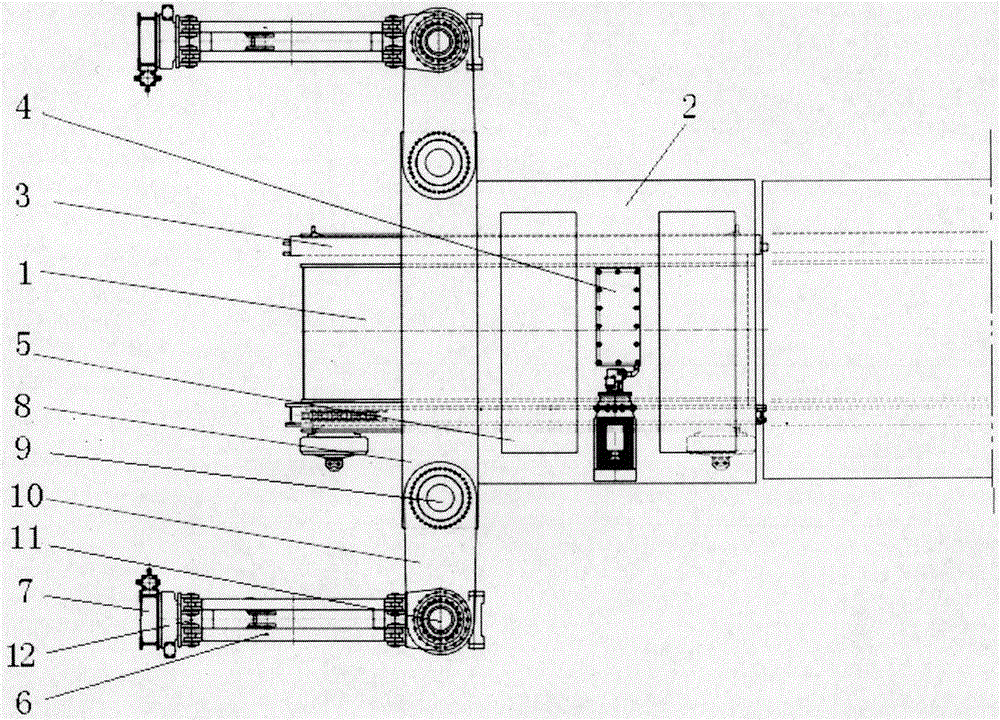

[0054] Such as Figure 1.1 with 1.2 As shown, a roadway excavation support robot is composed of a secondary transport chassis 1, a walking frame 2 installed on the secondary transport chassis 1, a lifting platform 5 mounted on the walking frame 2, a drilling anchor manipulator 4 and a hydraulic pump station and hydraulic operating system 4;

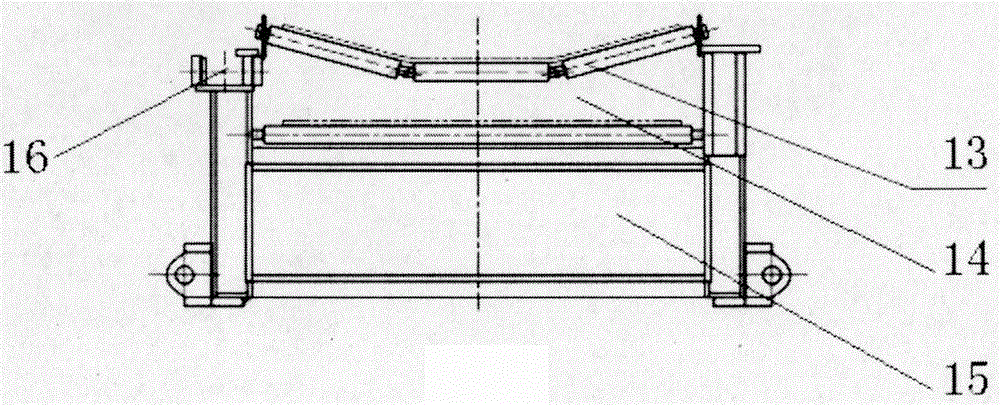

[0055] The structure of the second transport underframe 1 is as follows: Figure 2.1 , Figure 2.2 , Figure 2.3 As shown, the upper part is the U-shaped groove 14 of the second transport belt conveyor 13 for transporting gangue, and the lower part is an air channel 15 closed on all sides, and the two ends of the air channel 15 are provided with soft connection interfaces 3a, through which the second transport belt conveyor 3a is connected. The air passages between the chassis are softly connected to realize the function of the fan to ventilate the excavation face; the top of the sides of the U-shaped groove 14 is provided with a track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com