Roadway temporary supporting bracket with self-containing hoisting track and using method

A temporary support and track technology, which is applied in mine roof support, earthwork drilling, underground transportation, etc., can solve the problems of support lag, long installation time, and high labor intensity, so as to prevent crack expansion, reduce contact pressure, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

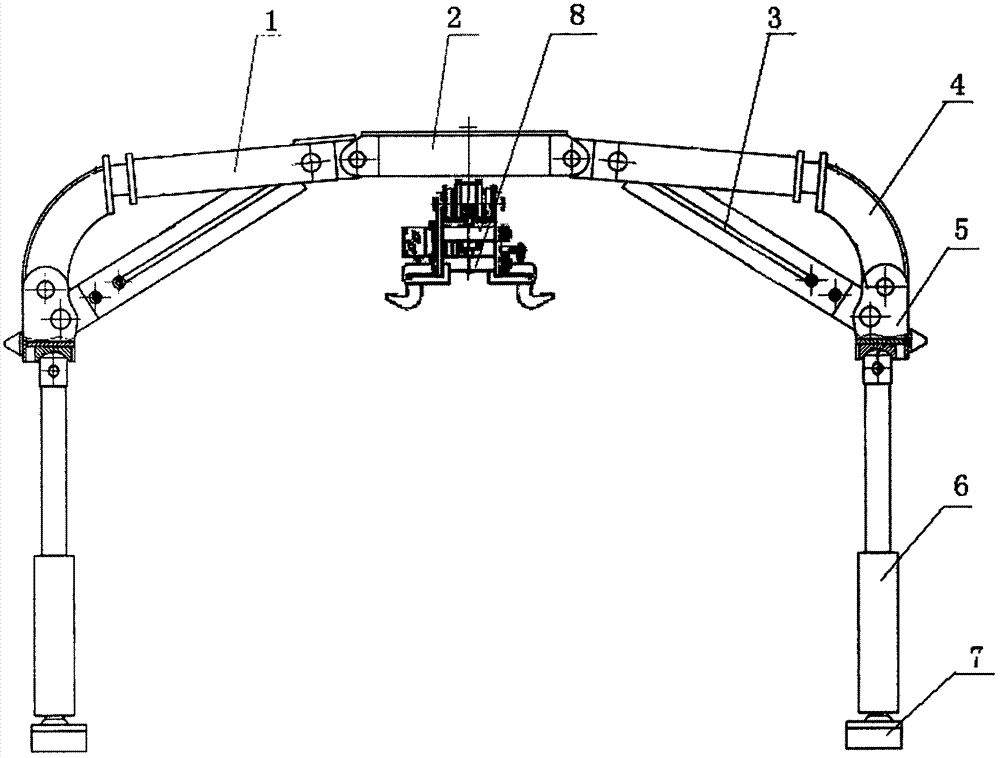

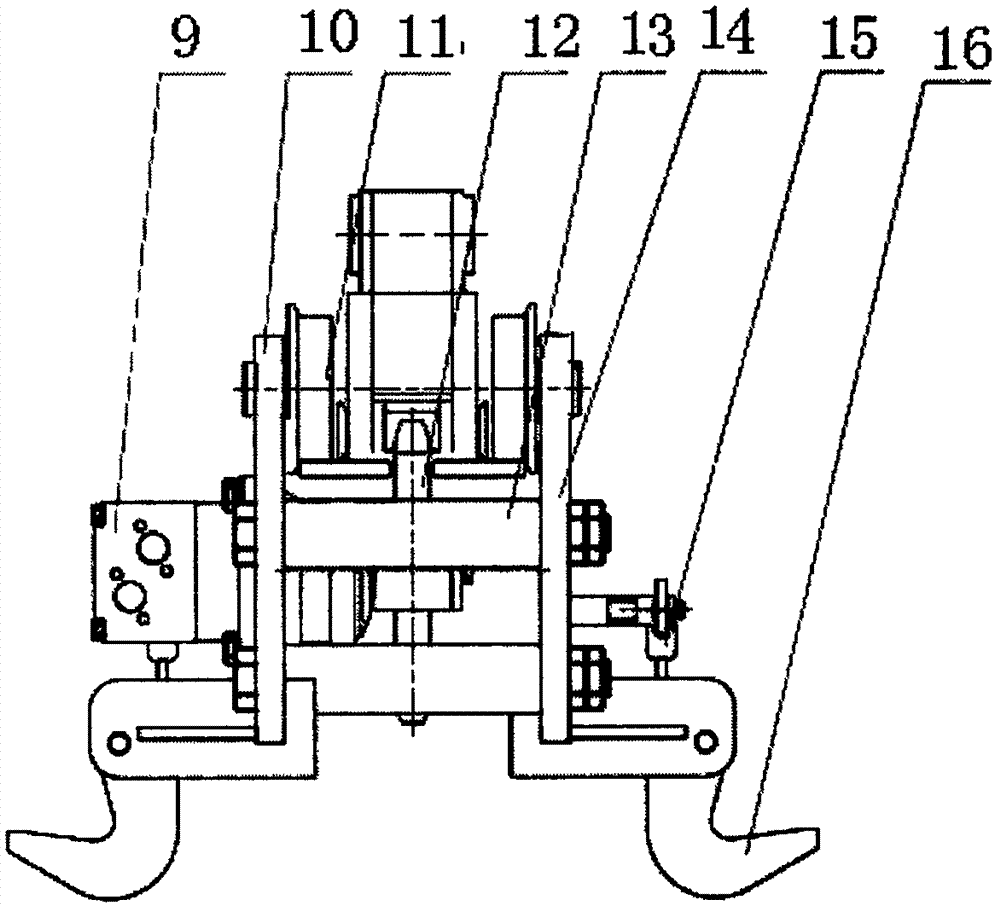

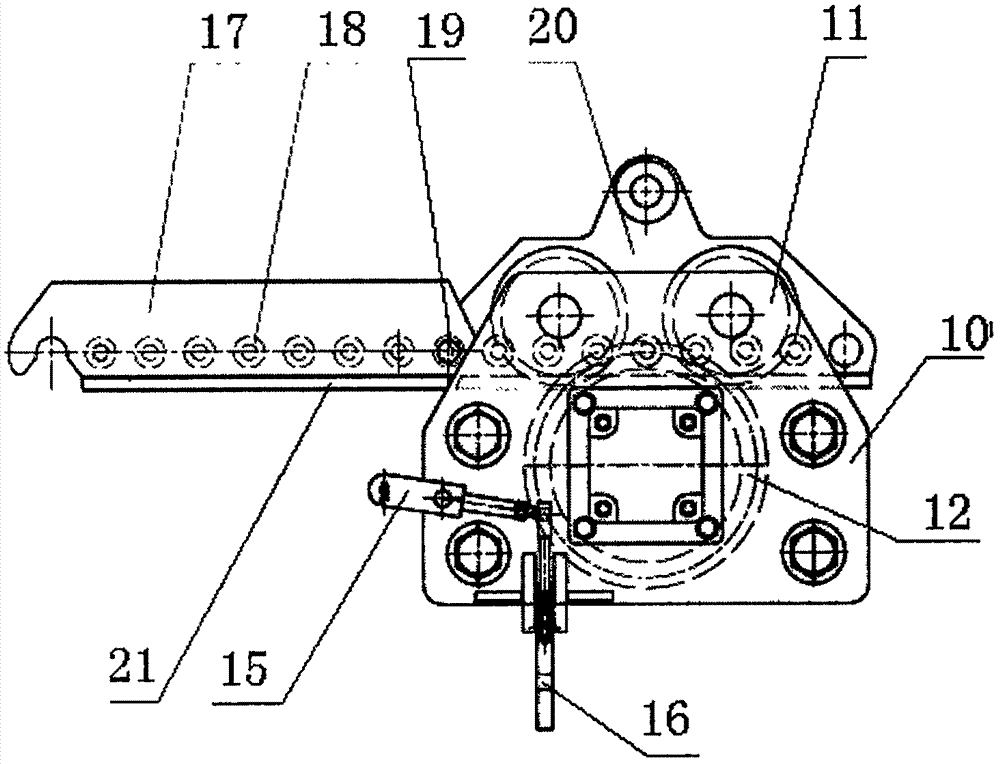

[0023] Such as figure 1 Shown, a kind of roadway temporary support frame with hoisting track of self-contained, comprises adjustable support and is installed in the conveyer 8 below the middle of adjustable support top beam; The supporting leg oil cylinder 6, the top supporting oil cylinder 3, the side beam 4 and the support frame 5 are composed; the crossbeam is composed of the middle beam 2 and the sleeve beams 1 on both sides of the middle beam; the middle beam 2 and the sleeve beam 1 are hinged Connection, the support leg oil cylinder 6 is connected with the support frame 5 using a ball joint ball and socket connection structure, the support frame 5 is hinged with the side beam 4 by a pin shaft, and the side beam 4 is connected with the telescopic inner cylinder of the sleeve beam 1; One end of the jacking cylinder 3 is hingedly connected to the side beam 4, and the other end is hinged to the sleeve beam 1. When the jacking cylinder 3 stretches, the pulling motion of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com