Pneumatic catapult-assisted take-off device and method used for unmanned plane

A technology of air pressure and air storage tank, which is applied in the direction of launch/drag transmission device, etc., can solve the problems of low ejection end speed of the catapult, limit the popularization and use of the catapult, and low ejection weight of the catapult device, so as to improve the ejection efficiency and reduce the maintenance. Cost, convenient transportation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

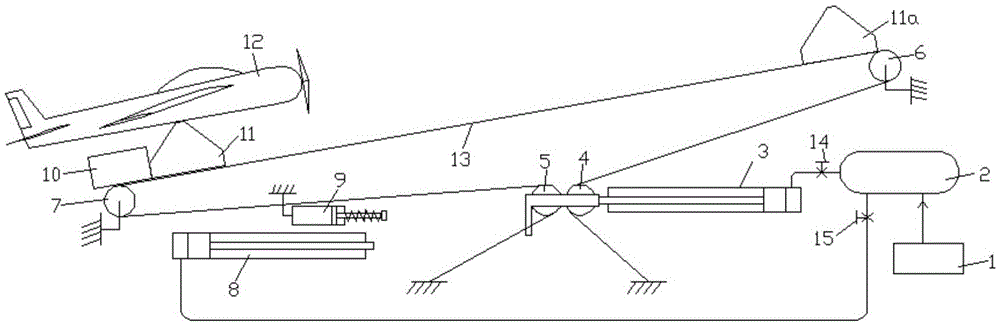

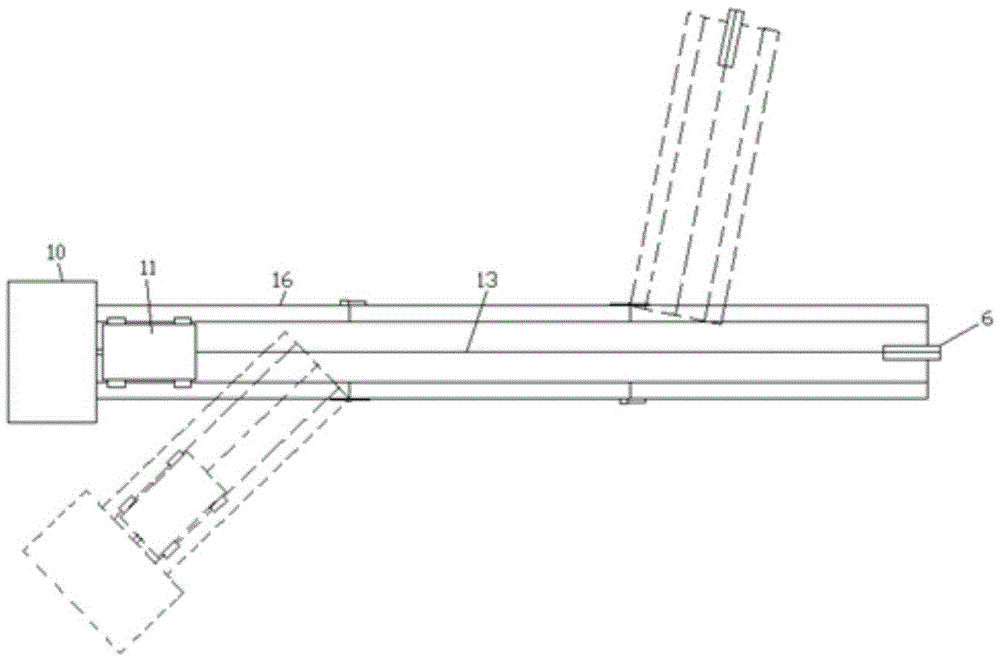

[0022] combined with figure 1 , the air pressure catapult take-off device of the present invention comprises an air compressor 1, an air storage tank 2, an action cylinder 3, a locking device 10, a guide rail 16, a steel cable 13, a block of pulleys and a guide rail block, wherein the block of pulleys includes a block of drive pulleys and a block of guide pulleys, The drive pulley set is composed of the first pulley 4, the second pulley 5 and the L-shaped ejector rod, and the guide pulley set is composed of the third pulley 6 and the fourth pulley 7 and is fixedly connected with the launch frame; wherein the compressor 1 is connected with the gas storage The tank 2 is connected and can pressurize the gas storage tank 2, one end of the action cylinder 3 communicates with the gas outlet of the gas storage tank 2, and the piston rod in the action cylinder 3 is fixedly connected with the L-shaped ejector rod; the steel Cable 13 walks around the third pulley 6 and the fourth pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com