Sleeve sealing device

A sleeve type, sleeve technology, applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as leakage, thermal stress cannot be eliminated, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

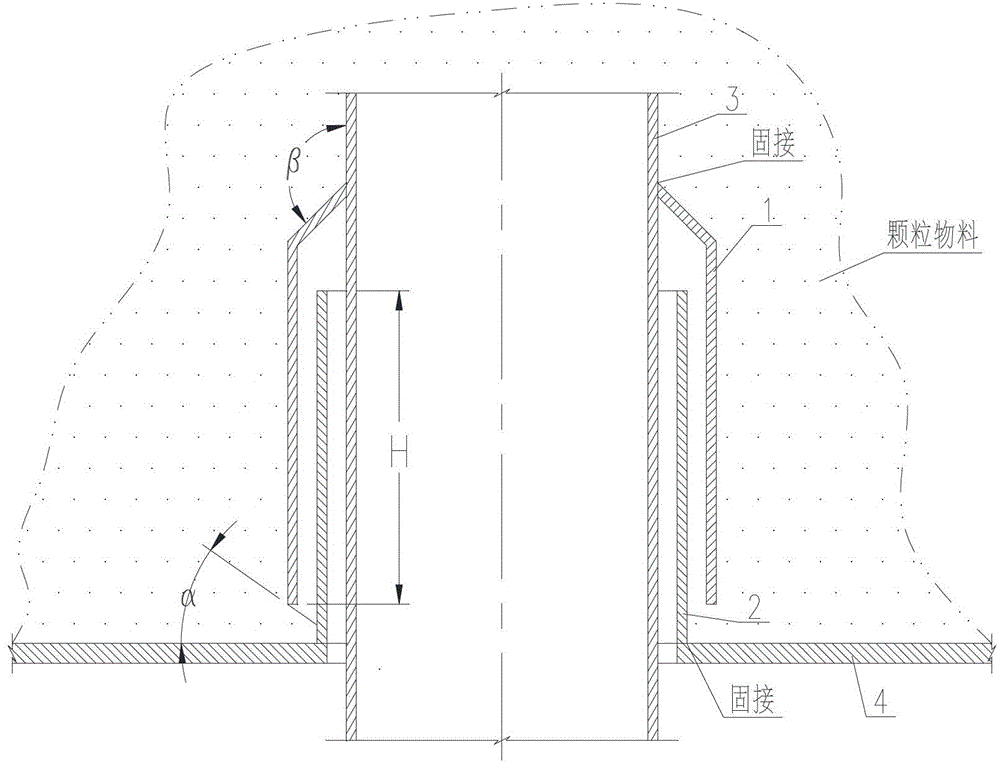

[0012] like figure 1 As shown, the upper sleeve 1 and the lower sleeve 2 are set on the pipe 3; the upper end of the upper sleeve 1 is fixedly connected to the pipe 3, the lower end of the lower sleeve 2 is fixedly connected to the material layer bearing device 4, and the upper sleeve 1 is set on the lower sleeve Tube 2 outside. The lower end of the upper sleeve 1 is an open pipe end, and the upper end of the lower sleeve 2 is an open pipe end. The upper sleeve 1 and the lower sleeve 2 partially overlap in height, and their overlapping height H should be determined through process calculation in advance. Under the action of the angle of repose α, the material level of the granular material is not enough to submerge the upper end of the lower sleeve 2, so there will be no leakage, and material sealing can be realized. At the same time, the pipeline 3 and the material layer carrying device 4 can move relative to each other along the axis of the pipeline 3, but the range of mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com