Canopy type material sealing device

An umbrella cover and bearing device technology, applied in the direction of pipes, pipes/pipe joints/pipes, mechanical equipment, etc., can solve problems such as inability to eliminate thermal stress at fixed joints, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

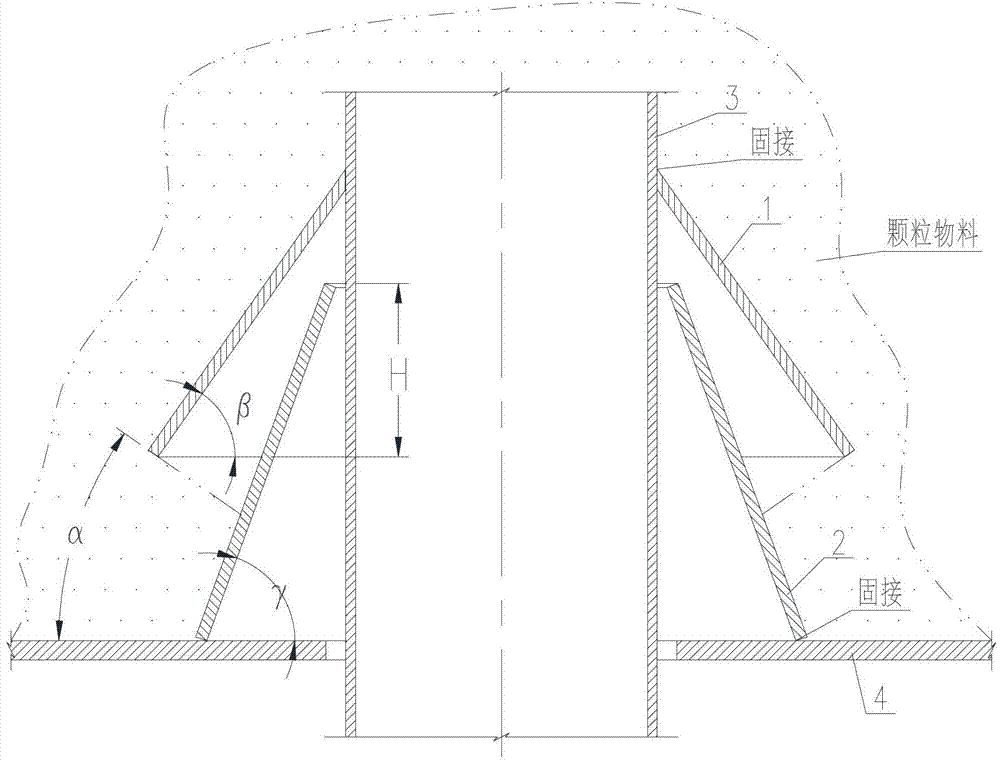

[0012] Such as figure 1 As shown, the present invention includes an upper canopy 1 , a lower canopy 2 , a pipeline 3 and a material layer carrying device 4 . Among them, the upper canopy and the lower canopy are both frustum-shaped hollow thin-walled structures, and the characteristic size of the upper section is smaller than that of the lower section. The layer carrying device 4 is fixedly connected, the lower end of the upper canopy 1 is loosely fitted outside the lower canopy 2; the upper end of the lower canopy 2 is loosely fitted inside the upper canopy 1 and outside the pipe 3, and the material layer carrying device 4 is loosely fitted on the pipe 3 outside. In this way, the material layer carrying device 4 and the pipeline 3 can move relatively within a certain height range along the axial direction of the pipeline, that is, the upper canopy 1 and the lower canopy 2 can move relatively in the height direction, but the range of movement cannot be too large, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com