Coal dust conveying device leakage monitoring and early warning device and method

A technology for monitoring and early warning and pulverized coal transportation, which is applied in the direction of measuring devices, testing of fluid tightness, testing of machine/structural components, etc., can solve problems such as low efficiency, heavy workload, and inability to monitor, and achieve detection sensitivity and High accuracy, reduce maintenance time, and ensure safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

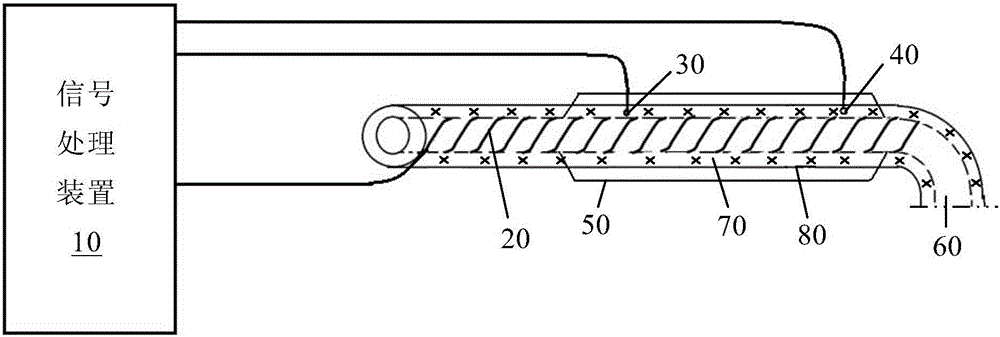

[0021] Such as figure 1 As shown, the leakage monitoring and early warning device of the present invention is used for monitoring, early warning and alarming whether a certain part is about to leak or has already occurred in the process of conveying pulverized coal by means of nitrogen in the pulverized coal conveying device. The traditional pulverized coal conveying device includes a conveying steel pipe 60 covered with an insulating layer 70 and a protective sheath 80 outside the conveying steel pipe 60. The pulverized coal is conveyed in the conveying steel pipe 60 by means of nitrogen.

[0022] As shown in the figure, the leakage monitoring and early warning device of the present invention includes a distributed temperature-sensing optical fiber 20 that is wound at intervals at a certain distance and pasted on the entire outer wall of the delivery steel pipe 60. Covered with an insulating layer 70 and a protective cover 80 (the insulating layer 70 and the protective cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com