Marine fuel vapor separator with vent control device

A technology of gas separator and ventilation valve, which is applied in the direction of charging system, machine/engine, liquid fuel feeder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

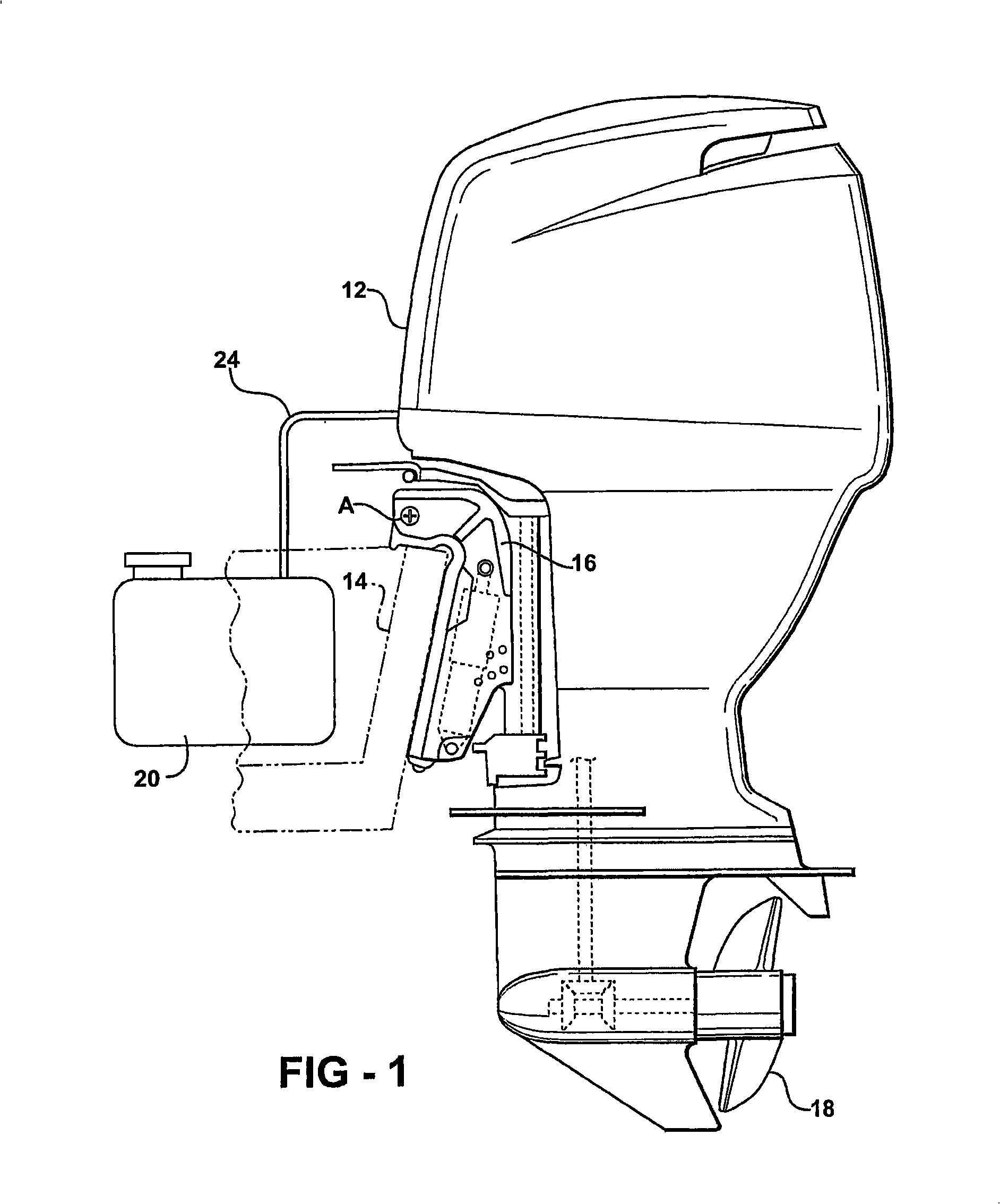

[0026] Referring to the drawings, wherein like numerals designate like or corresponding parts throughout the several figures, there is shown in FIG. 1 an outboard marine engine 12 attached to a transom 14 of a boat. Small outboard marine engines 12 of this type are typically mounted on a stand 16 so that the engine 12 can be quickly removed from the boat for transport and / or maintenance. The bracket 16 has an inclined structure, so that the motor head can be rotated into the boat, while the propeller 18 swings upwards away from the water, so as to start and move in a shallow state. For example, the motor 12 is pivotable about the A-axis between these use and non-use positions, as well for smooth control.

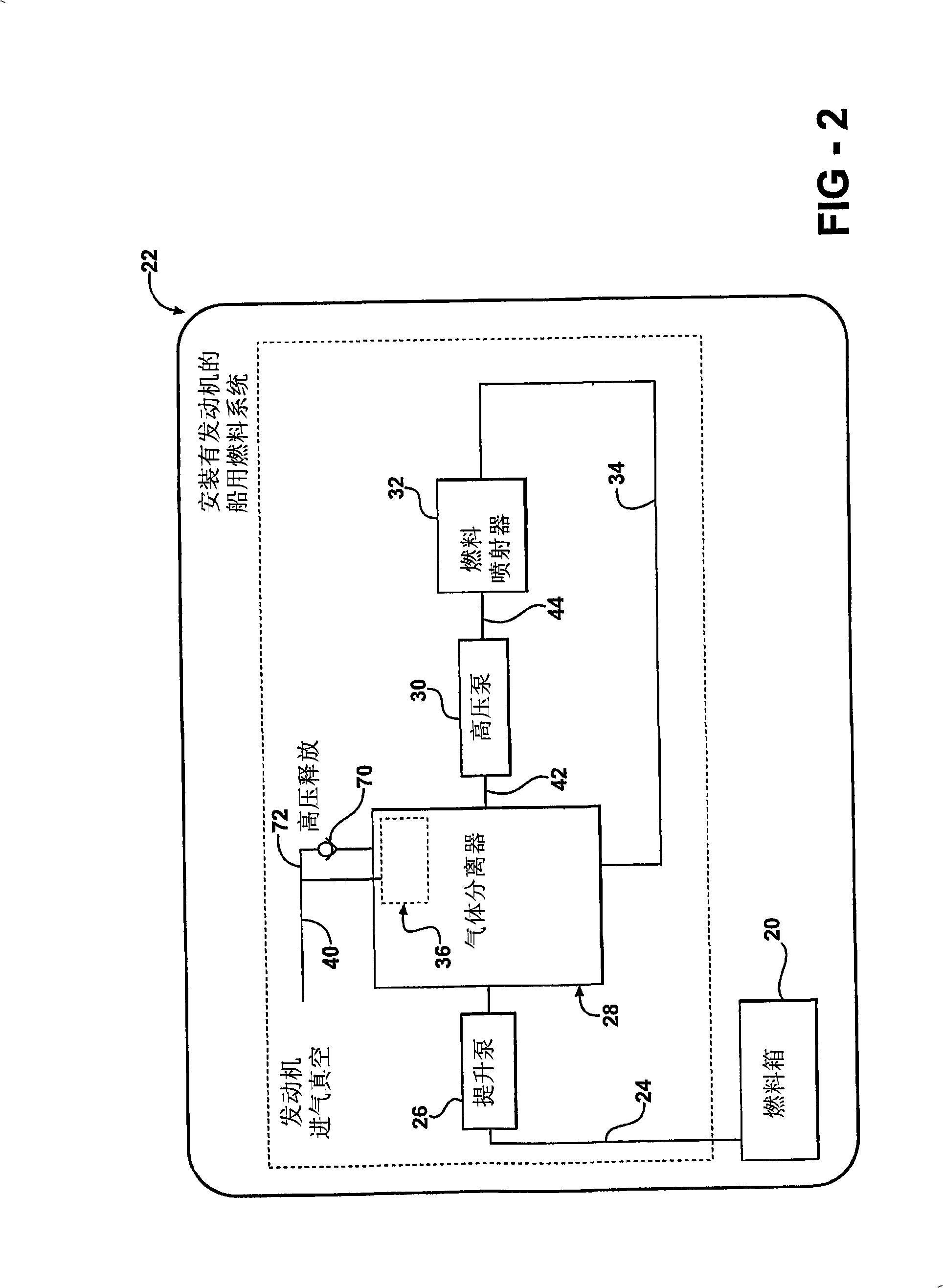

[0027] Engines of the type shown in Figure 1 typically run on liquid fuels like gasoline or ethanol. Liquid fuel is drawn from fuel tank 20 by an engine-mounted marine fuel system (shown generally at 22 in FIG. 2 ). With the exception of the fuel tank 20 and fuel supply li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com