Trailed combined working machine for ridging, furrowing, paving films and covering soil on film edges

A combined operation machine and traction technology, which is applied to agricultural machinery and tools, agriculture, shovels, etc., can solve the problems of loose soil covering at the edge of the film, easy blowing of the film by the wind, single function, etc., and achieve small weight and convenient transfer , The effect of simple machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

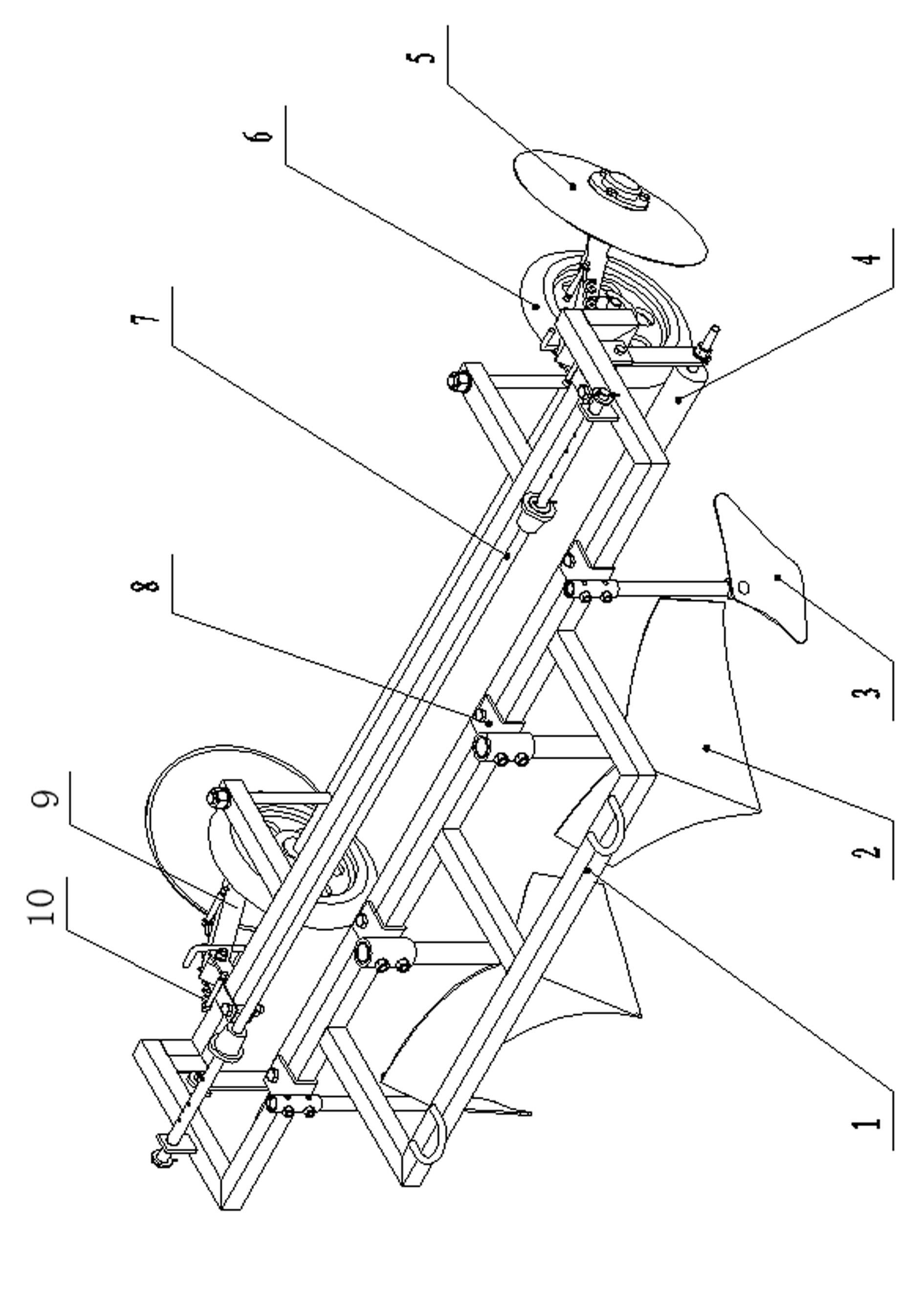

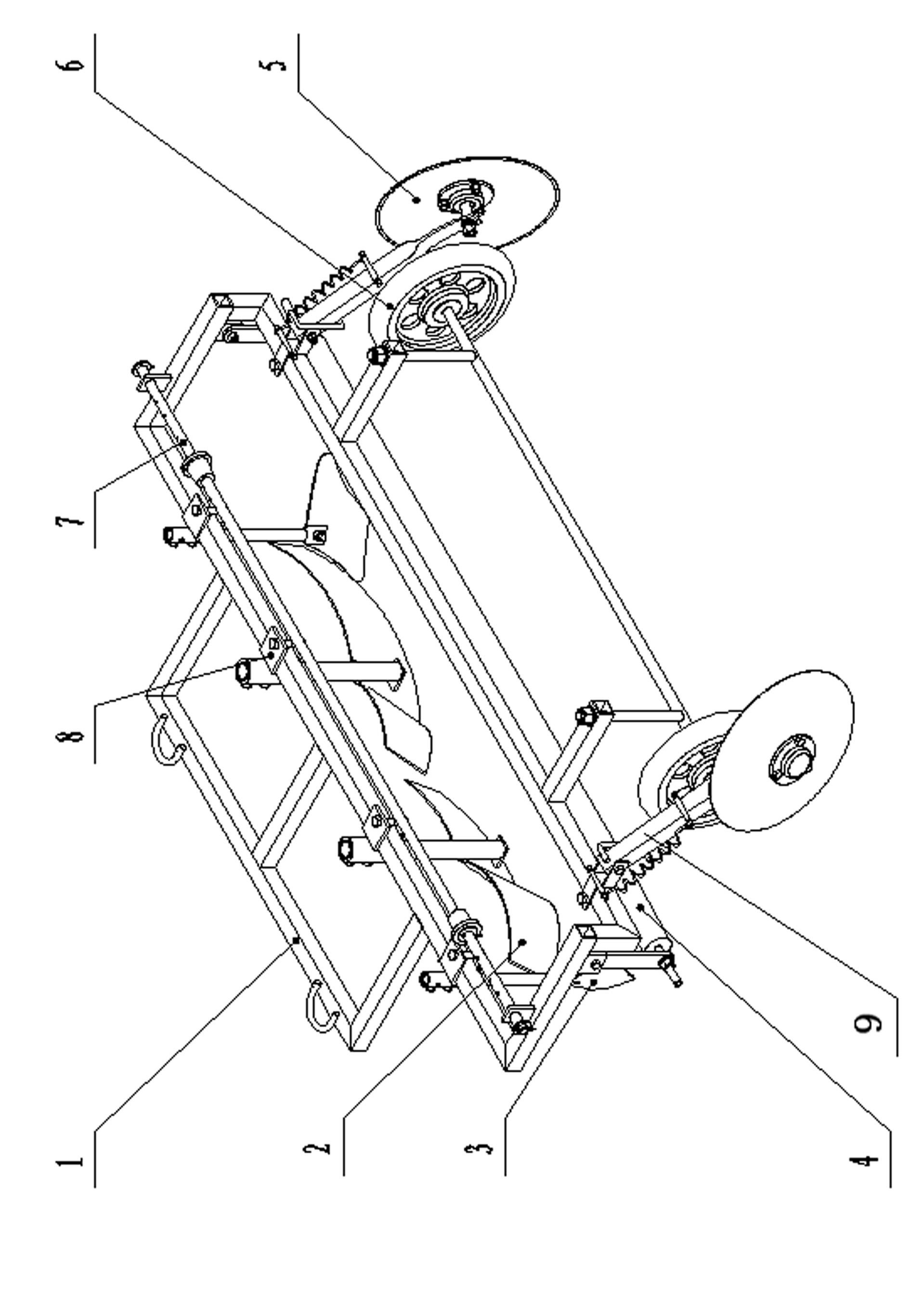

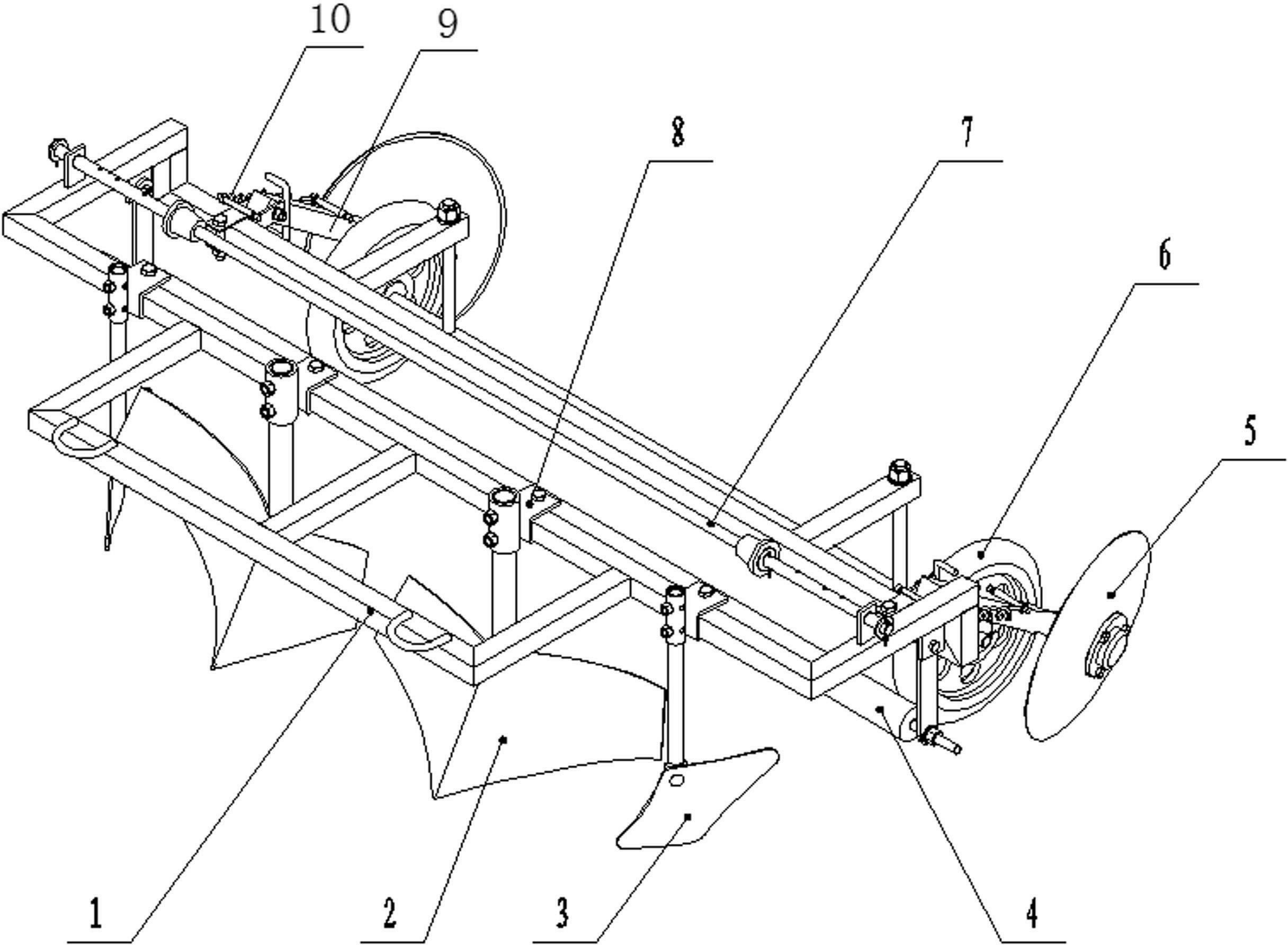

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0012] like figure 1 , figure 2 Shown: four fixed adjusters 8 are installed on the beam in the frame 1 by bolts, the middle two fixed adjusters 8 are installed with ditching shovels 2, and the two fixed adjusters 8 on both sides are installed with trenching shovels 3. A film hanging frame 7 is arranged above the left and right longitudinal beams of the frame 1, a film spreading roller 4 is arranged behind and below the film hanging frame 7, and two lamination films are installed behind the rear beam of the frame 1 corresponding to the position of the ditching shovel 3 Wheel 6, an outer overturning soil pan 5 is installed on the side and rear of the two lamination wheels 6, and the overturning soil pan 5 is hinged with the rear beam of the frame through a connecting rod 9, and a tension spring 10 is installed between the connecting rod 9 and the rear beam of the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com