Direct drive nut turning device

A technology of rotating device and nut, applied in the field of machine tools, can solve the problems of insufficient precision and rigidity of the transmission chain, and achieve the effect of improving dynamic performance and simplifying the structure of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

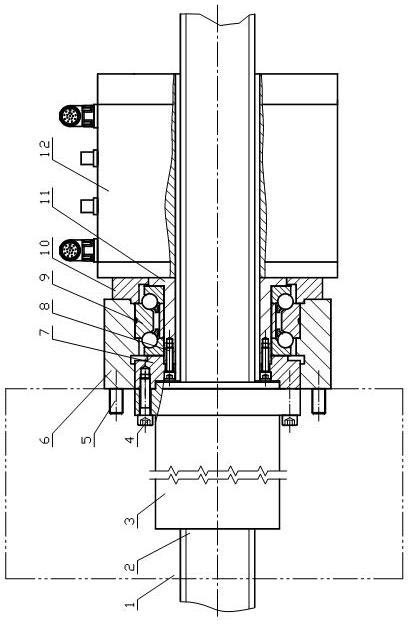

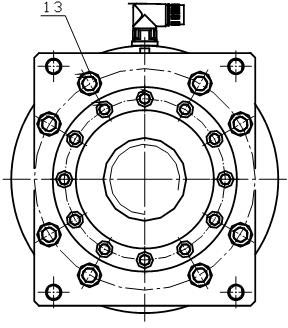

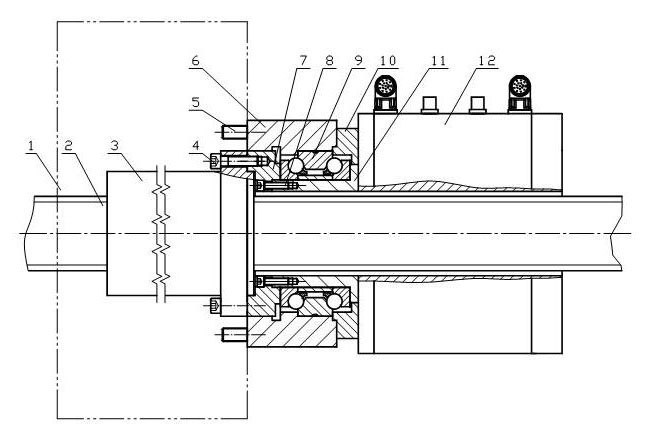

[0013] figure 1 , figure 2 As shown, the screw mandrel 2 of the present invention passes through the hollow torque motor 12, the rotating nut 3 is rigidly coupled on the screw mandrel 2, the bearing 9 is installed on the rotary bushing 11, and the rotary bushing 11 is fixed to the rotor of the hollow torque motor 12 Connection, the bearing 9 is used to bear the axial load to ensure the accuracy of axial movement, the connecting body 7 is connected with the rotary sleeve 11 through the hexagon socket head screw 8, and the inner ring of the bearing 9 is fixed; the rotating nut 3 on the screw rod 2 passes through the inner The hexagonal screw 4 is connected with the connecting body 7; the connecting flange 6 is installed on the outer ring of the two-way thrust ball bearing 9, and is connected with the bearing end cover 10 and the shell of the hollow shaft torque motor 12 through the inner hexagonal screw 13, and the bearing 9 The outer ring is fixed; the socket head cap screw 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com