Integrated biomass molding machine with internal circular mold

An inner ring die and integrated machine technology, applied in material forming presses, presses, manufacturing tools, etc., can solve the problem that materials cannot be distributed evenly in time and productivity, achieve simple structure, improve stability, and eliminate eccentric loads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

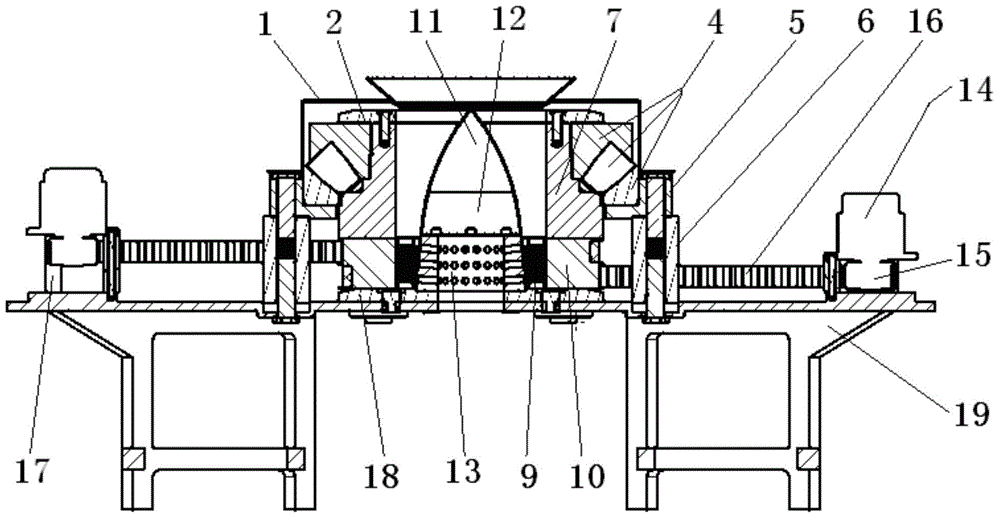

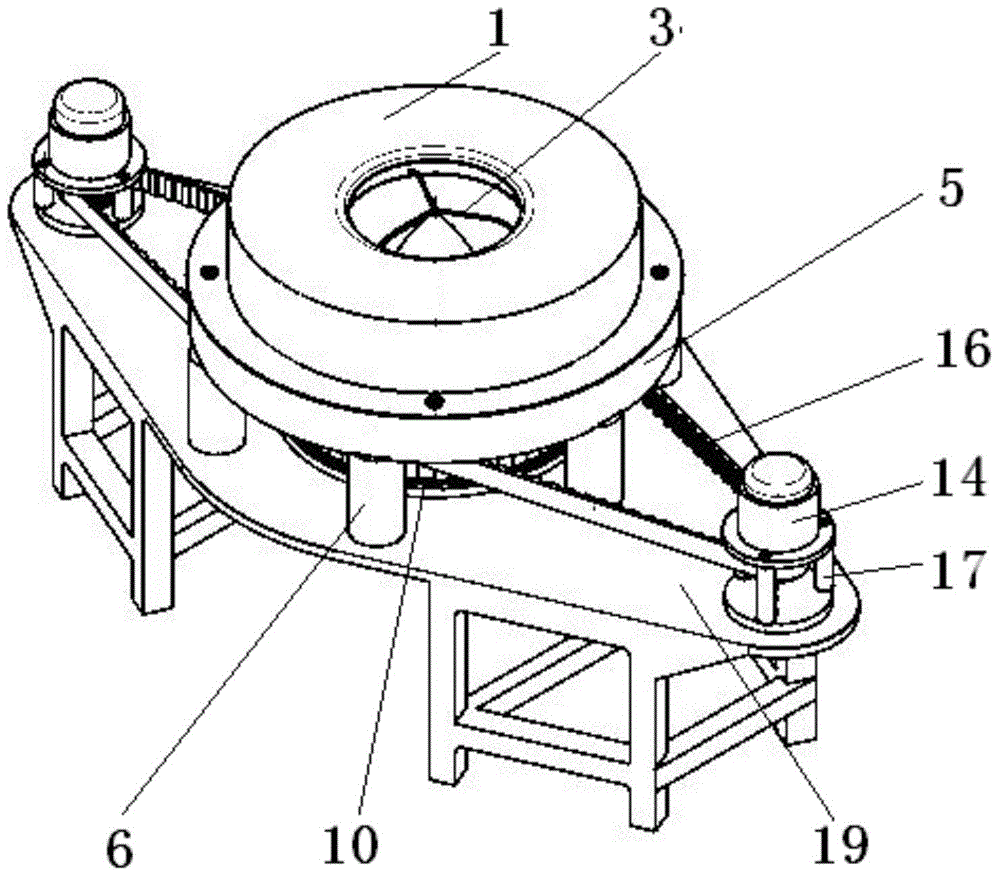

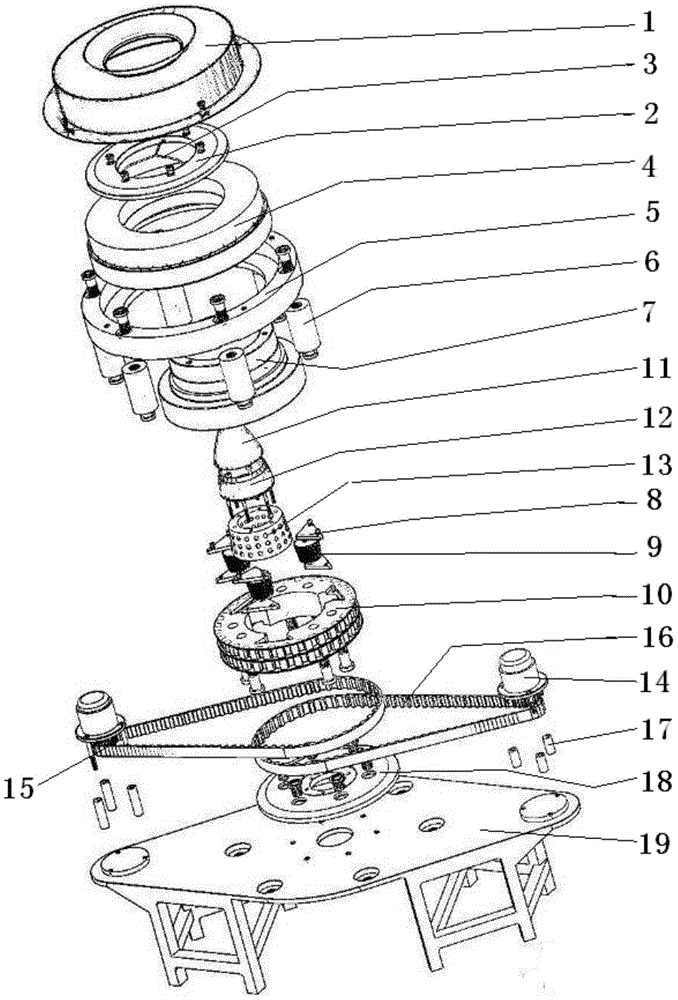

[0031] The specific structure and working process of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0032] figure 1 It is the front and full cross-sectional view of the biomass inner ring mold forming machine, figure 2 It is the three-dimensional structure diagram of the biomass inner ring molding machine, image 3It is an exploded view of the assembly of the biomass internal ring molding machine. As shown in Figure 3, the inner ring mold fixing plate 18 is fixedly connected to the center of the frame panel set horizontally on the frame 19, the center hole of the inner ring mold fixing plate 18 is coaxial with the center hole of the frame panel, and the inner ring mold 13 is coaxial with the central hole of the inner ring mold fixing plate 18 and is fixedly connected to the inner ring mold fixing plate 18. There are forming holes 1301 on the wall of the inner ring mold 13. Two motors 14 are symmetrically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com