Progressive die for C-shaped clamping frame

A technology of progressive die and clamping frame, which is applied in the field of progressive die, can solve the problems of low work efficiency, achieve the effect of improving work efficiency and preventing up and down fluttering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

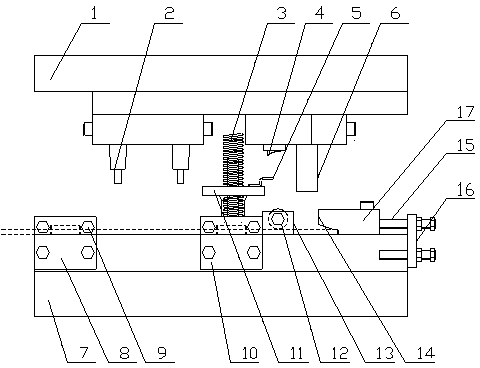

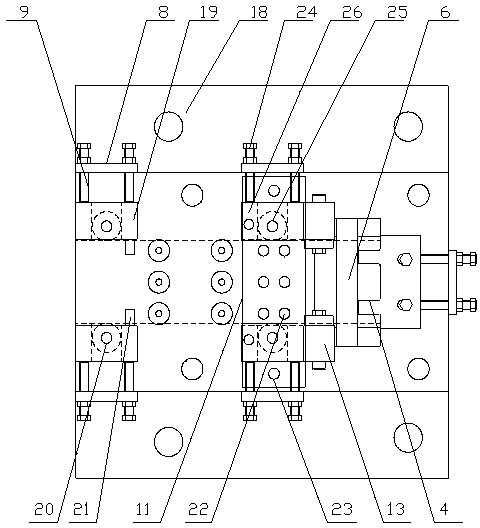

[0021] Such as figure 1 and figure 2 As can be seen from the schematic diagram shown, the C-shaped clamp frame progressive die of the present invention includes a frame 18, an upper die 1, a lower die 7, a stamping mechanism, a detection mechanism, a cutting mechanism, a pushing mechanism and a blocking mechanism.

[0022] The upper die 1 and the lower die 7 are installed on the frame 18, and between the upper die 1 and the lower die 7 are sequentially distributed a stamping mechanism, a detection mechanism, a cutting mechanism, a pushing mechanism and a blocking mechanism.

[0023] The stamping mechanism includes a stamping punch 2. The stamping punch 2 has two horizontal rows, and the two rows of stamping punches 2 are arranged in sequence along the conveying direction of the material. The upper end of the stamping punch 2 is fixed to the lower surface of the upper die 1. , At the same time, a blanking hole corresponding to the stamping punch 1 is provided at the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com