Automatic thread cutting device in multi-needle machine

A multi-needle machine and automatic technology, applied in the field of machinery, can solve the problems of deviation between the actual sliding track of the movable knife and the predetermined track, the influence of the accuracy of the tangent process, and the failure of tangent, so as to achieve uniform force, prevent up and down jumping, and restore accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

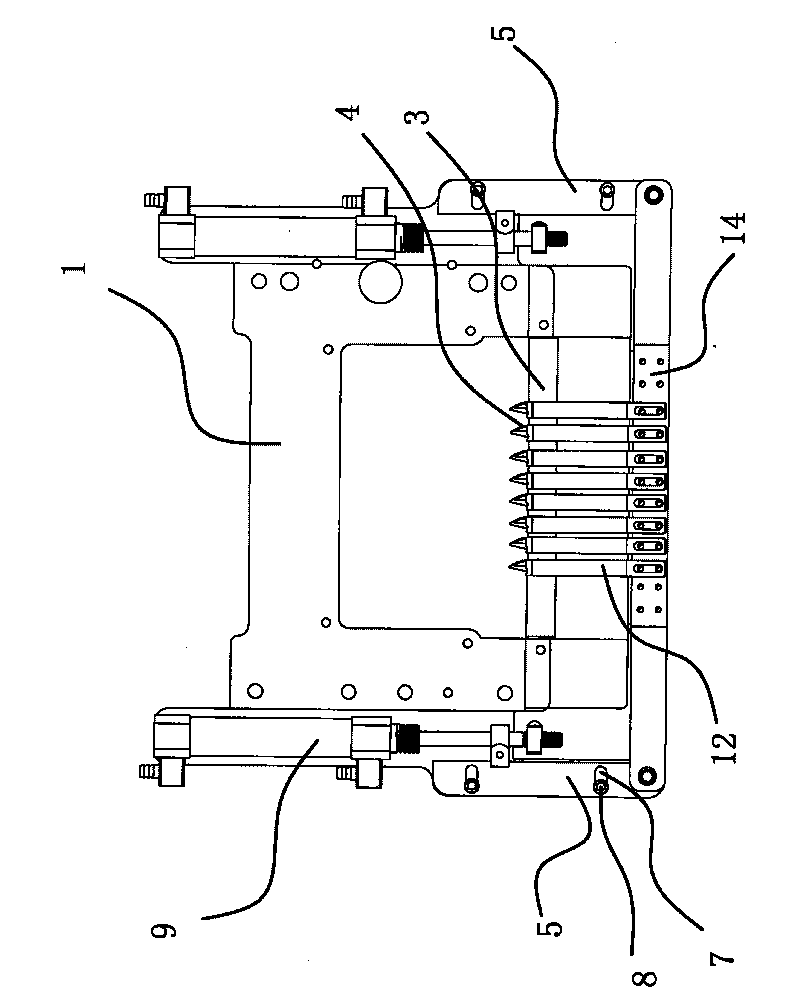

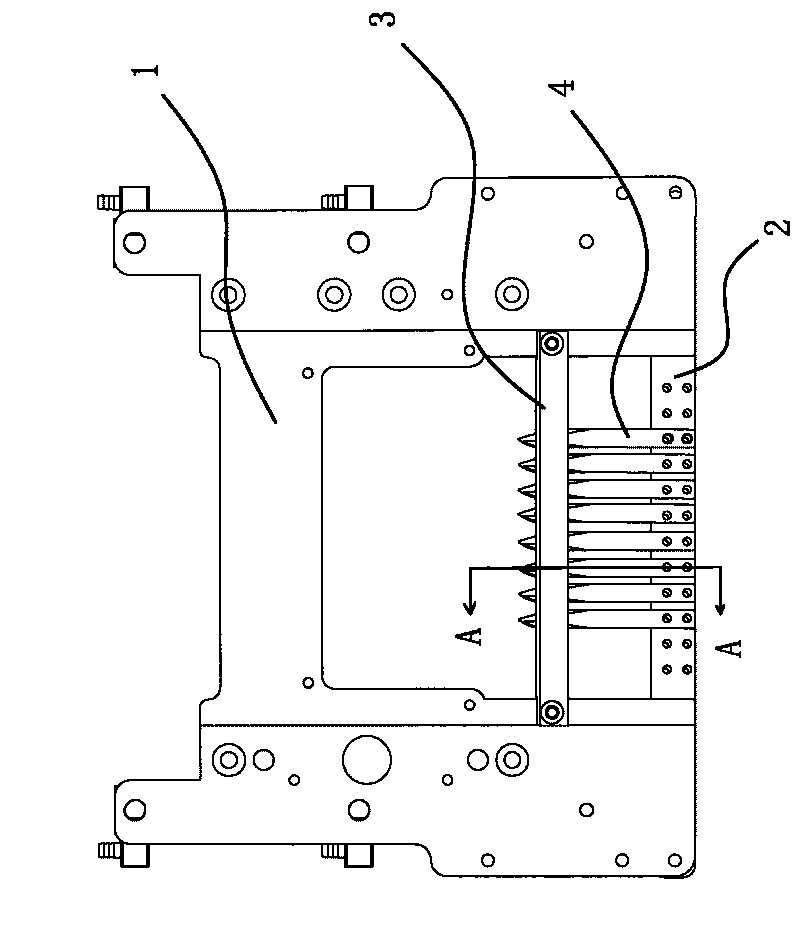

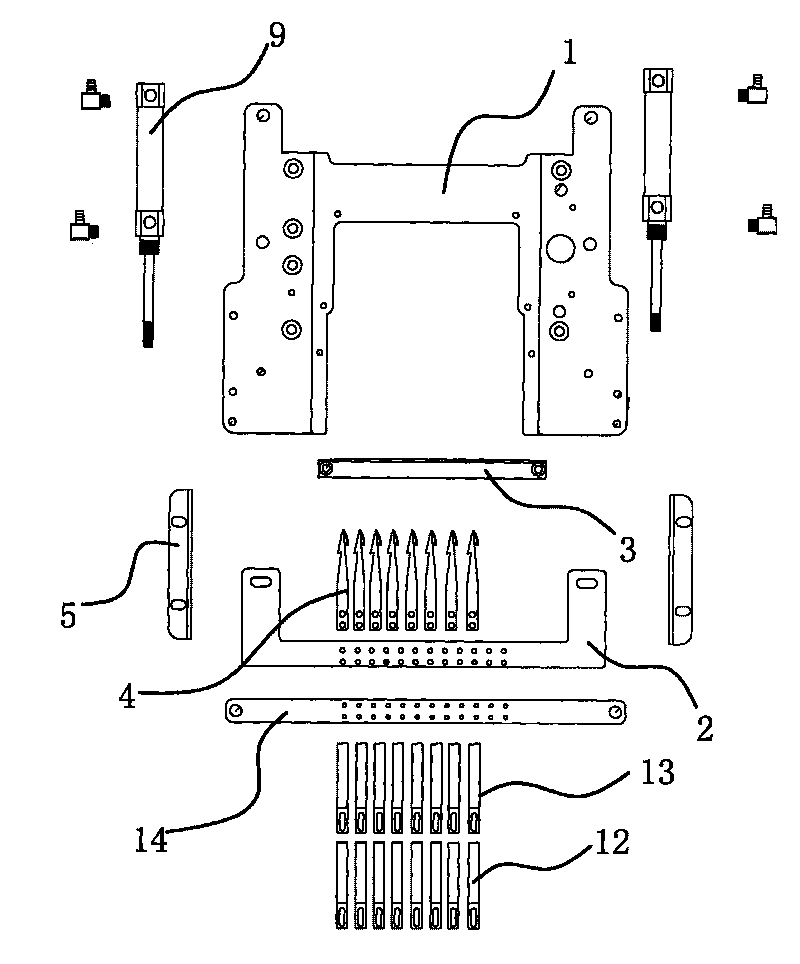

[0027] like figure 1 and figure 2 and image 3 As shown, the automatic thread cutting device in the multi-needle machine is arranged at the machine head of the multi-needle machine, including the needle plate pad 1 and the movable knife rest 2 arranged on the needle plate pad 1, and the needle plate pad 1 is horizontally fixed with Be the fixed knife 3 of strip shape. Movable knife rest 2 is fixedly provided with several movable knives 4, and the quantity of movable knives 4 is 8 to 12 in the present embodiment, but as another kind of scheme, the quantity of movable knives 4 also can be other numerical value, movable knife 4 Be fixed on the movable knife rest 2 successively. The movable knife rest 2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com