Quality closed-loop control method for automatic machining

A closed-loop control and processing quality technology, applied in automatic control devices, metal processing, metal processing equipment, etc., can solve the problems of lack of quality closed-loop control methods, and the processing quality of thin-walled shells cannot be effectively guaranteed, so as to avoid quality problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

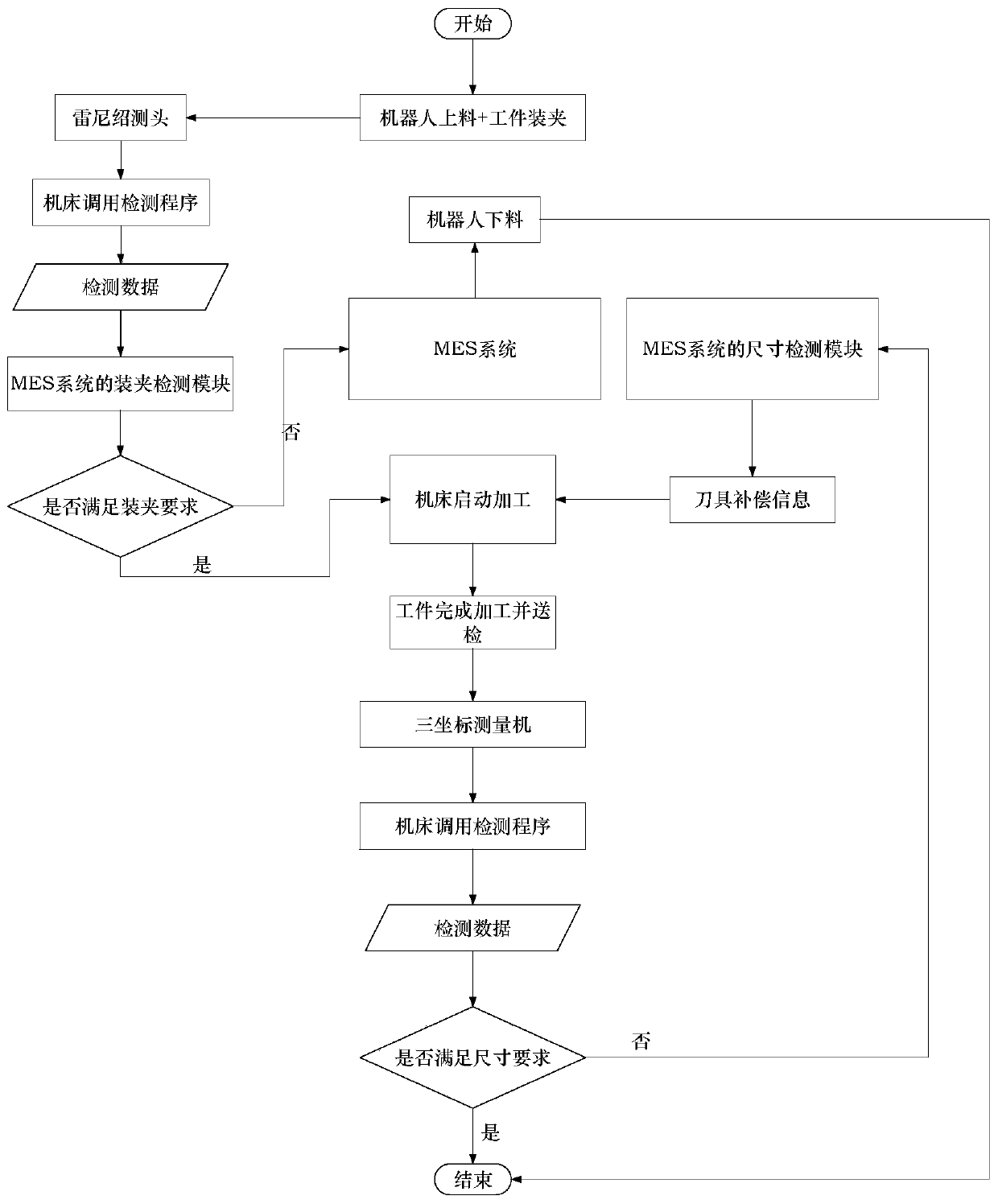

[0031] In this embodiment, an automatic processing quality closed-loop control method is specifically provided to realize the quality closed-loop control of thin-walled and weakly rigid parts, and the processing accuracy can be controlled at ±0.02mm. This control method is mainly based on MES system and automated processing production line, among which, the MES system is the production process execution system of the manufacturing enterprise, which is a set of production information management system oriented to the execution layer of the workshop of the manufacturing enterprise; the automated processing production line refers to the realization of the product process by the automated machine system A form of production organization. It is formed on the basis of the further development of the continuous assembly line. Its characteristics are: the processing object is automatically transferred from one machine tool to another machine tool, and the machine tool automatically per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com