Cashmere combing method

A cashmere and carding technology, which is applied in deburring devices, textiles and papermaking, fiber treatment, etc., can solve the problems of increased carding cost, complex structure, and large damage to cashmere fiber length, etc., and achieve equipment structure simplification, The effect of little damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

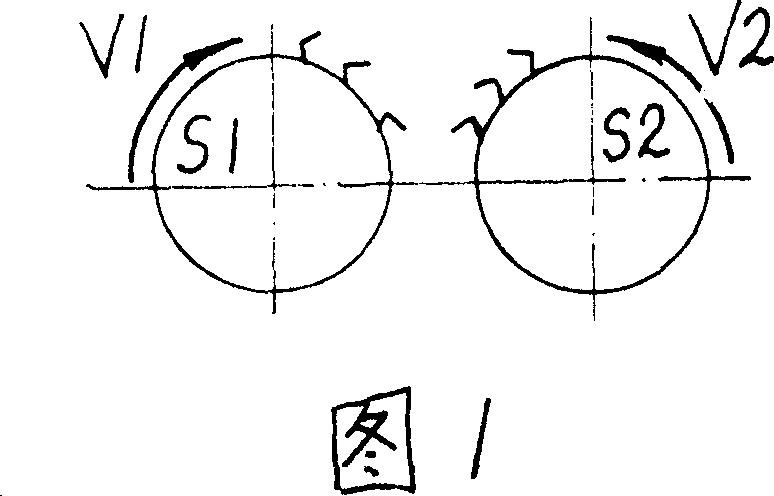

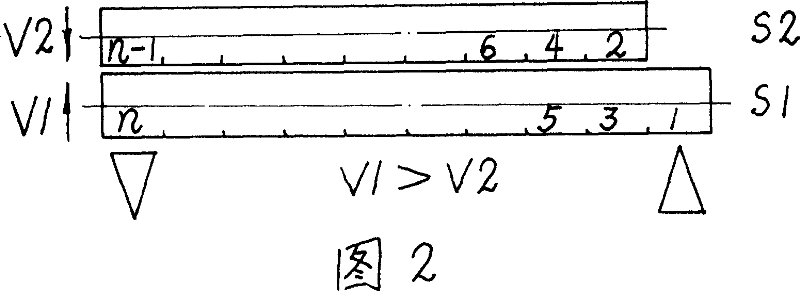

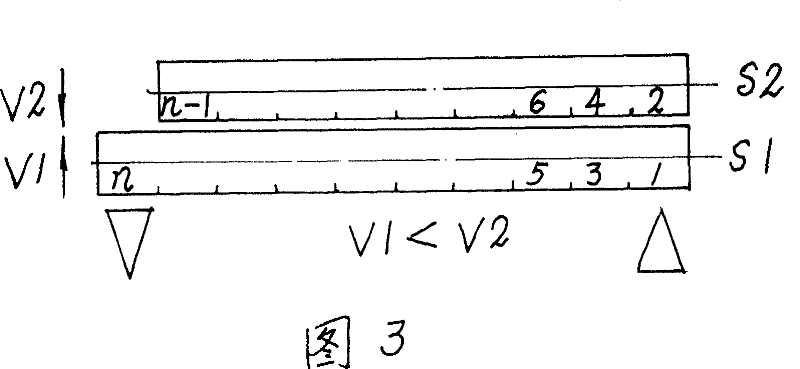

[0009] As shown in Figure 1, the two opening rollers S1 long roller and S2 short roller are arranged in parallel and the needle directions are in the same direction. When the cashmere is fed from the first section of the S1 long roller through the feeding device, the S1 long roller is running at a high speed and is located at the far right end, while the S2 short roller is running at a low speed and is located at the leftmost end, and the end faces of the two rollers are at the exit of the machine. end flush (see Figure 2). After running for a period of time, the S1 long roller decelerates to low-speed operation, and its position moves to the leftmost end; while the S2 short roller speeds up to high-speed operation, its position moves to the rightmost end, and the end faces of the two rollers are flush at the feeding end (see Figure 3 ). Since the line speed of the short roll of S2 is greater than that of the long roll of S1 at this time, the fibers on the long roll of S1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com