Intensifying sewage whole-course autotrophic nitrogen removal reactor and intensifying sewage whole-course autotrophic nitrogen removal method

A whole-process autotrophic denitrification and reactor technology, which is applied in the field of strengthening the whole-process autotrophic denitrification reactor for sewage, can solve the problems of difficult enrichment of autotrophic denitrification functional flora and low denitrification efficiency, and achieves an increase in biomass. and reactivity, simplify the process flow, and improve the effect of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

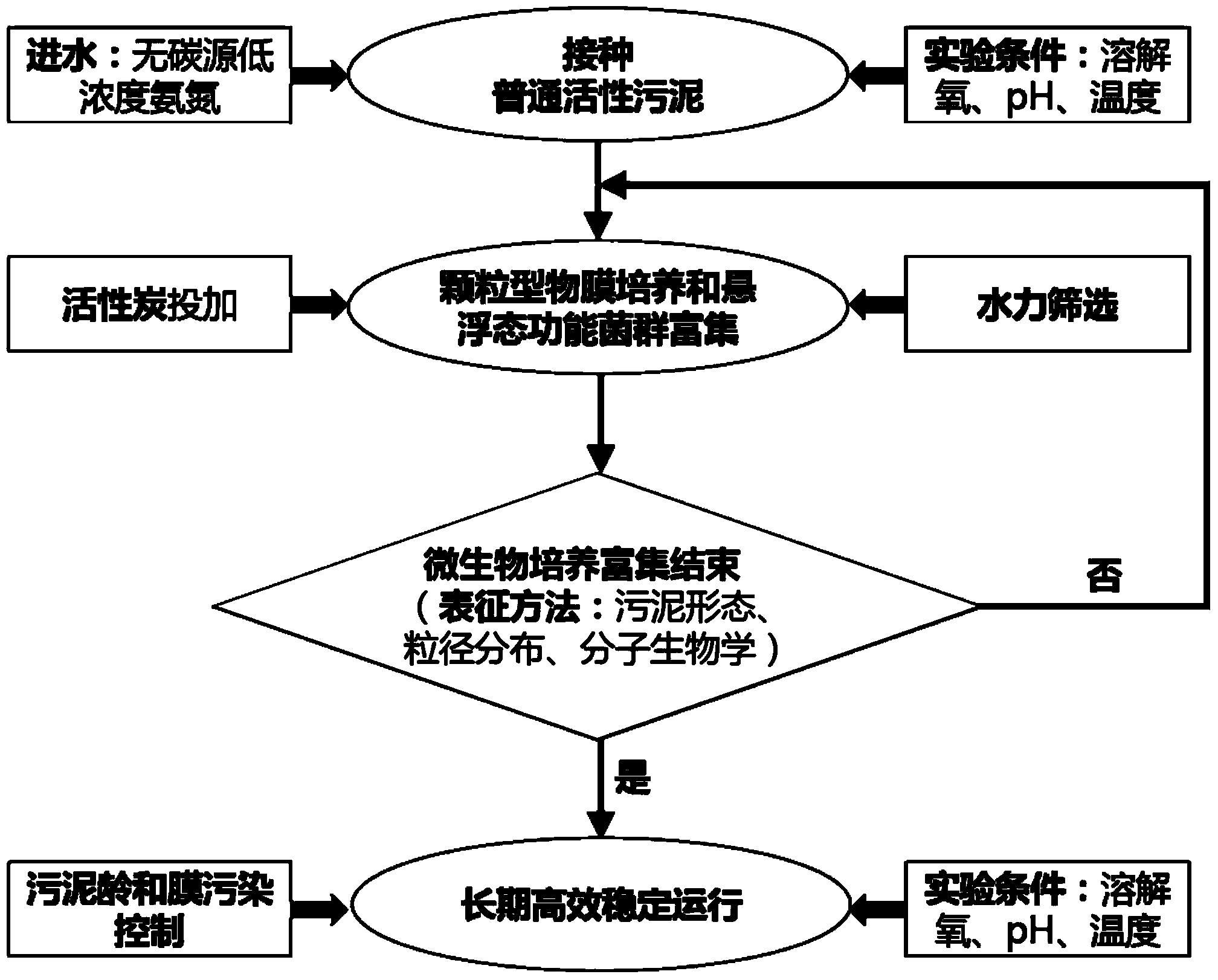

[0022] In order to solve the problems existing in the prior art, such as the difficulty in the enrichment of functional flora and the low load of ammonia nitrogen removal, the present invention provides an enhanced sewage autotrophic denitrification reactor and method, which realizes particle-based biofilm denitrification in the same reactor. The coupling of the two technologies of microbial immobilization and membrane interception-based enrichment of suspended bacteria can increase biomass and its reactivity, and effectively remove ammonia nitrogen, organic matter and suspended matter in sewage.

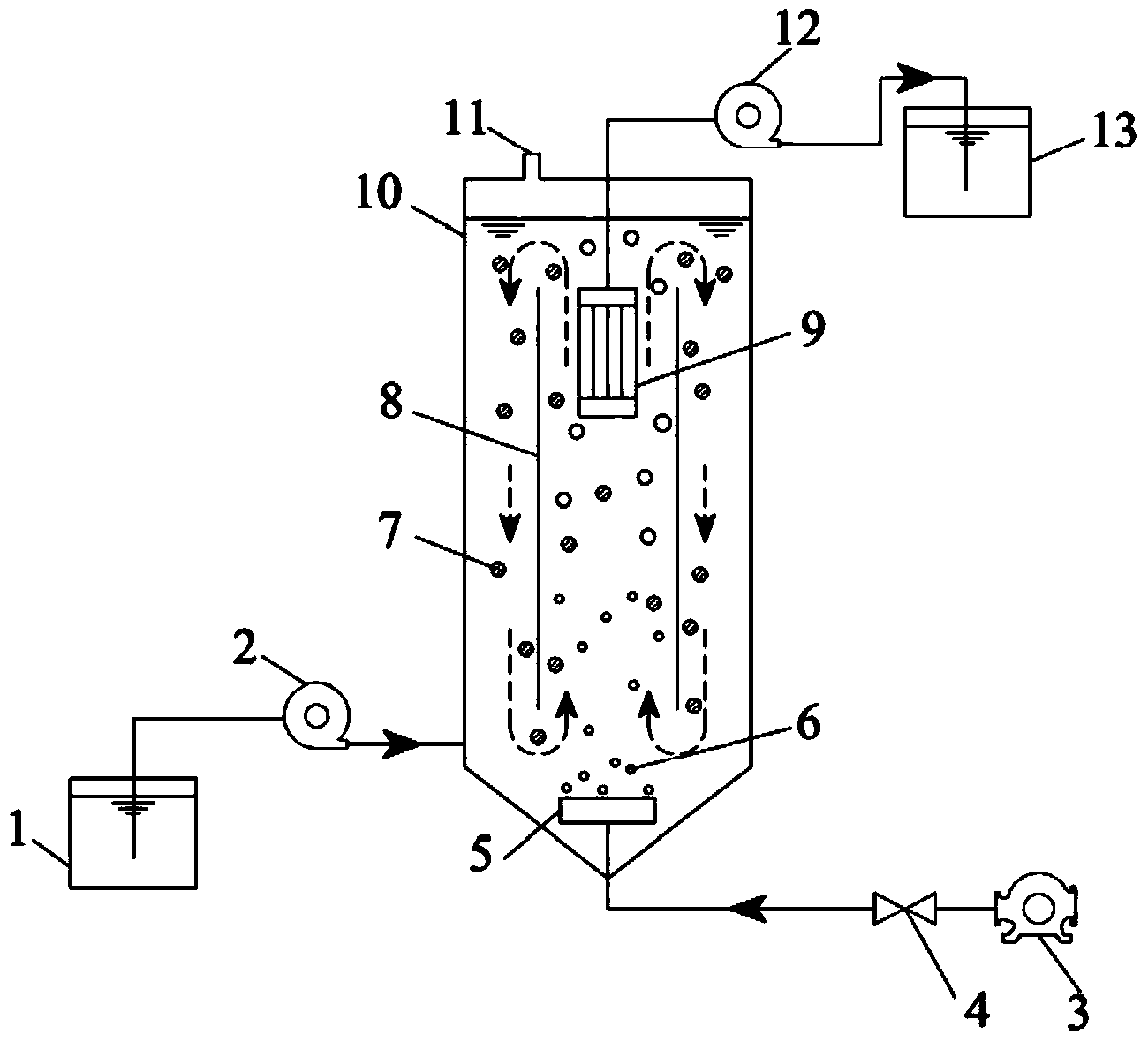

[0023] Such as figure 1 As shown, in the embodiment of the present invention, an enhanced sewage full autotrophic denitrification reactor mainly includes a reaction tank 10 and a microporous aerator 5 , a guide tube 8 and a membrane module 9 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com