Concentration homogenization method of hydrocarbon-containing waste gas

A waste gas and concentration technology, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of limited concentration homogenization effect and limited adsorption capacity of high-concentration hydrocarbon-containing waste gas, and achieve good concentration homogenization effect, Conducive to stable operation and large buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The hydrocarbon-containing waste gas discharged from an acidic water tank, due to the quality of the influent water, in the exhaust gas caused by water inflow, drainage and temperature changes, the volume content of hydrocarbons varies within the range of 1% to 12%, and the average concentration within a certain period is 5 %about.

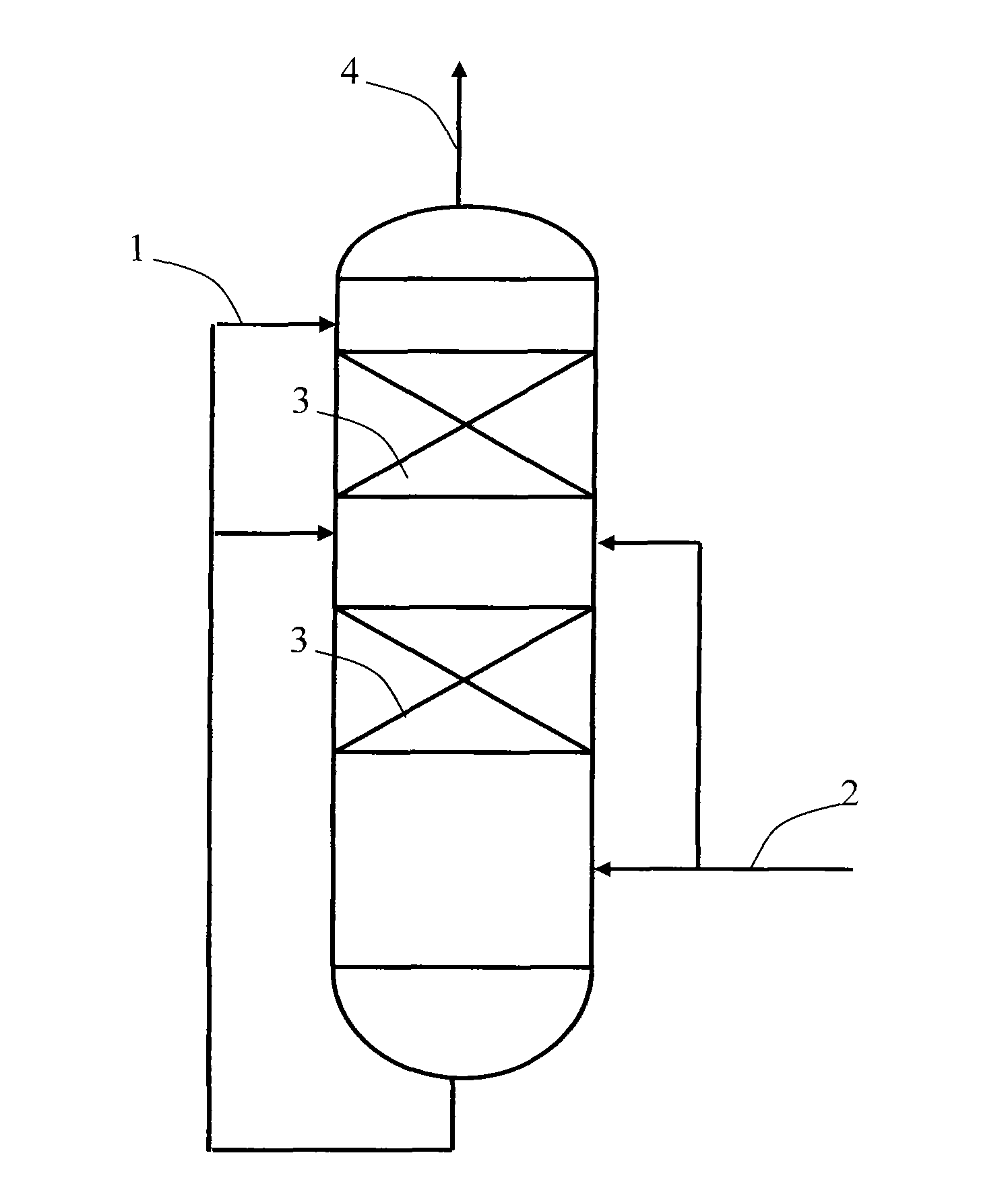

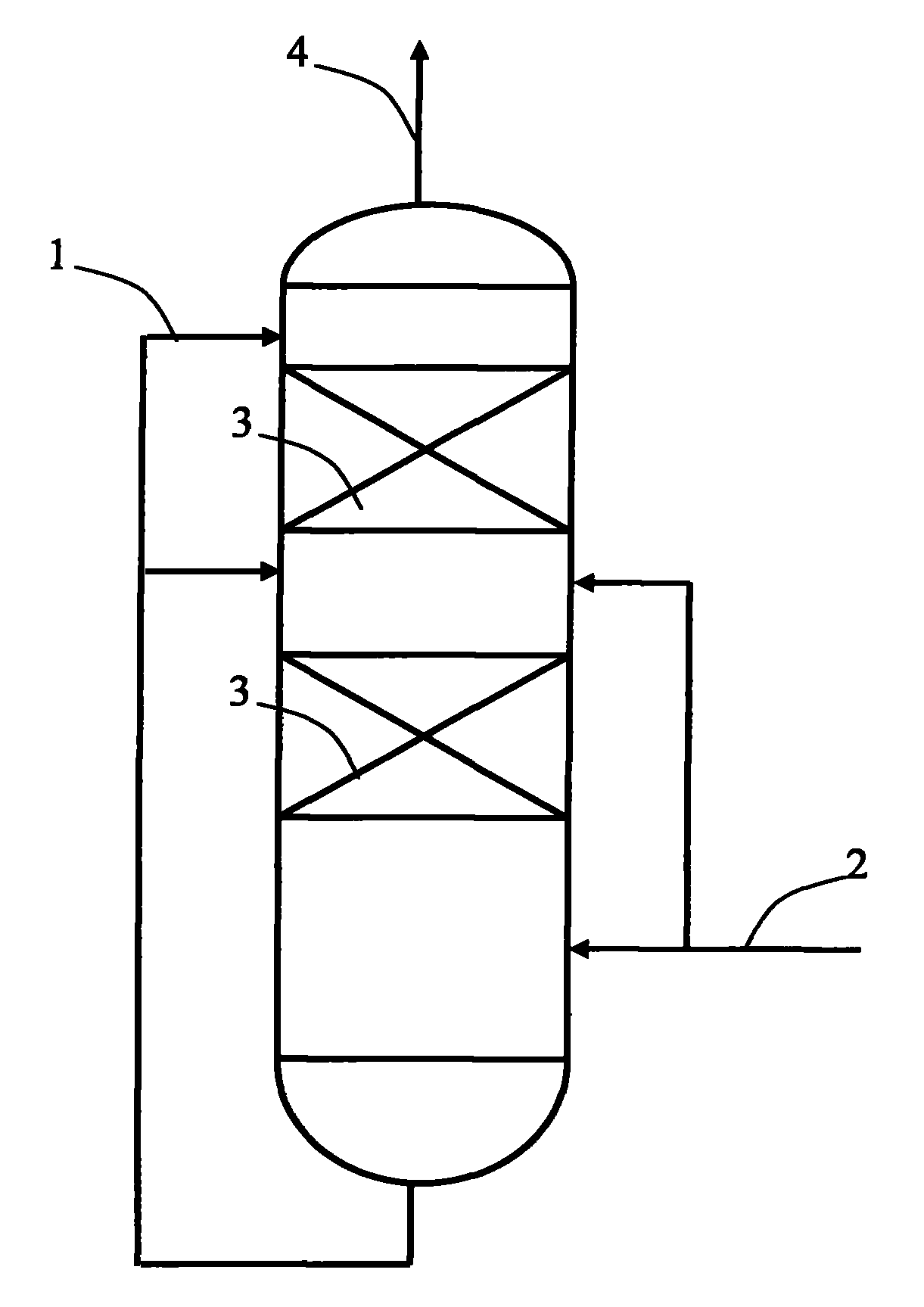

[0021] Diesel oil with a distillation range temperature of 220-350°C is used as solvent oil, and a bubble column is used. A gas distributor is installed in the middle of the bubble column for secondary gas-liquid contact distribution. The hydrocarbon-containing waste gas enters the bubble column from the bottom of the column. Exhausted from the top of the tower, the volume space velocity of the exhaust gas is 1000h -1 , after 48 hours of stable operation, the concentration of hydrocarbons in the exhaust fluctuates in the range of 4.2% to 7.8% (volume).

Embodiment 2

[0023] The concentration of total hydrocarbons in the discharge gas from a certain alkali slag tank farm ranges from 3% to 20% (volume), and the average concentration within a period of time is 8% (volume).

[0024] Diesel oil with a distillation range temperature of 250-380°C is used as solvent oil, and a spray packed tower is used. The circulating solvent oil circulates from the bottom of the tower to the top of the tower, and the hydrocarbon-containing waste gas enters the spray packed tower from the bottom of the tower, and is discharged from the top of the tower. The shower tower adopts stainless steel Pall ring packing with a packing of Φ25mm×25mm×2mm, and the spray liquid-gas ratio is 30L / m 3 , the volume space velocity of exhaust gas is 800h -1 , after 48 hours of stable operation, the concentration of hydrocarbons in the exhaust fluctuates in the range of 6% to 12% (volume).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com