Method for stripping off green husk of nut through mechanized dry process

A walnut green peeling and peeling technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve problems such as difficulty in ensuring the surface of nuts, reduced value of finished walnut nuts, and serious pollution at the processing site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, the present invention will be further described in conjunction with the accompanying drawings.

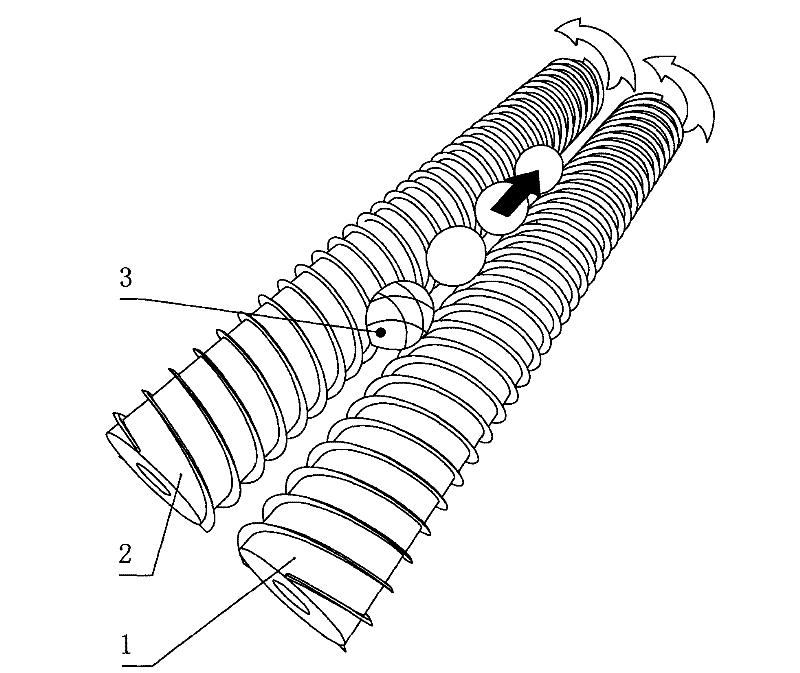

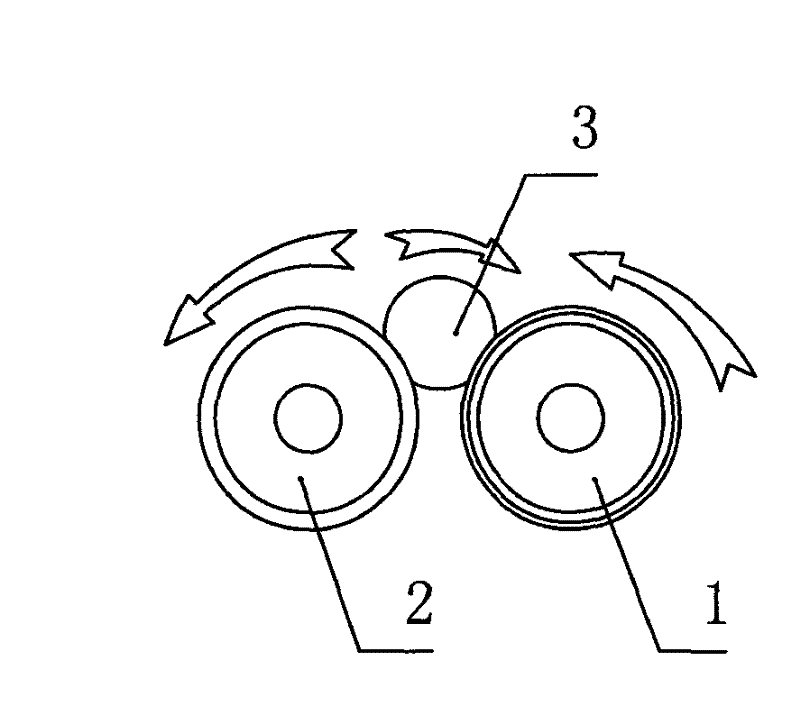

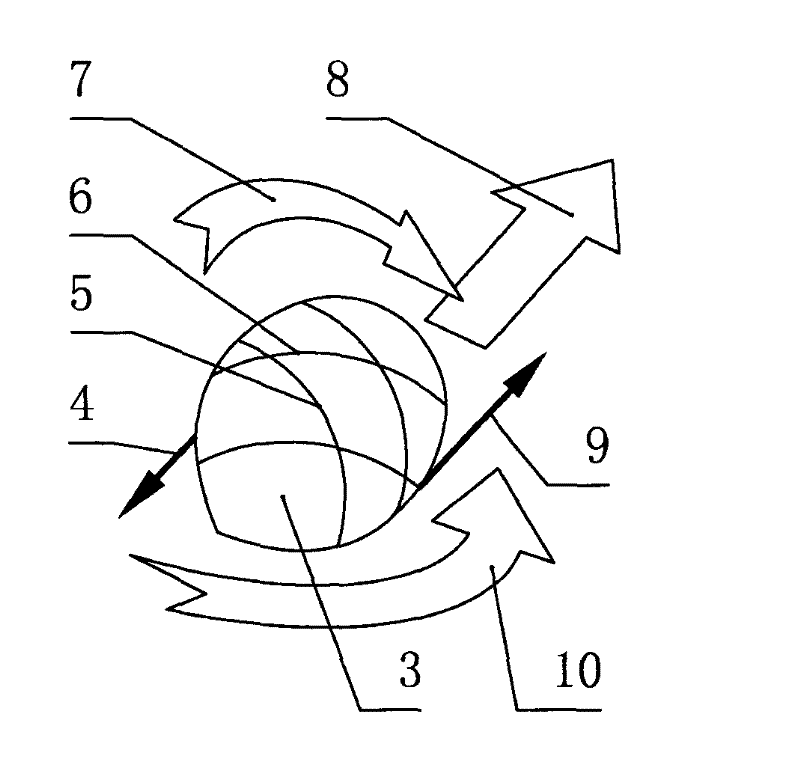

[0013] The present invention is a method for mechanized dry peeling of walnut green skin, which uses two right-handed spiral knife rollers 1 and left-handed spiral knife rollers 2 with opposite helical directions but the same direction of rotation and different speeds on fermented and mature green walnuts. 3. Cross-shaped left-handed spiral cut marks 5 and right-handed spiral cut marks 6 are cut out on the surface; the tangential force applied to the walnut fruit by the edge of the spiral knife roller makes the walnut fruit rotate vertically along the direction shown in 7, because figure 1 The rotating speed of middle right-handed spiral knife roller 1 is faster than the rotating speed of left-handed spiral knife roller 2 (also can be vice versa), so the axial force 9 applied by right-handed spiral knife roller to green walnut fruit 3 is higher than the axial force app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com