Detection method of full-automatic background module detector

A technology of a backlight module and a detection method, applied in the field of detection machines, can solve the problems of low accuracy and low efficiency, and achieve the effect of high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

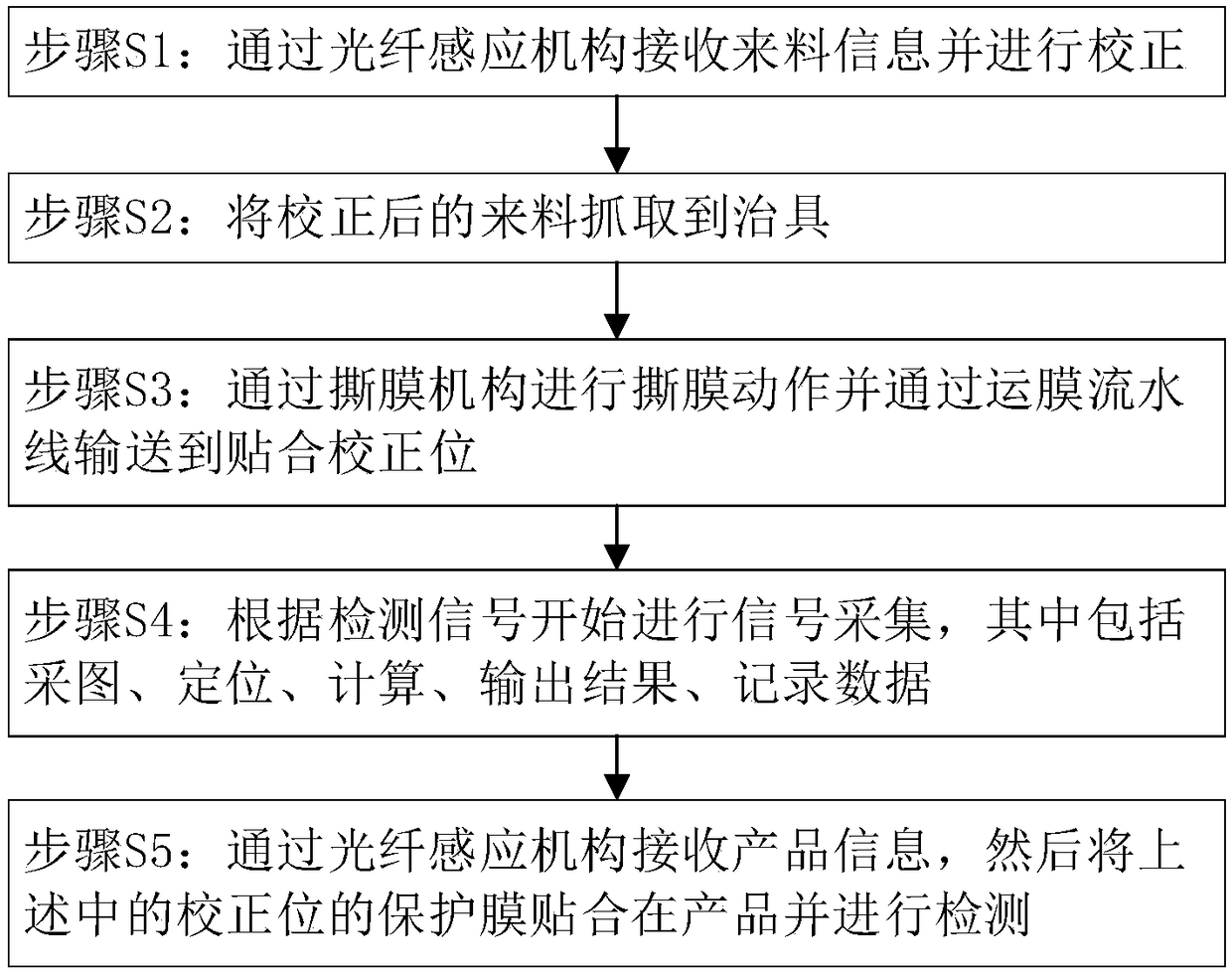

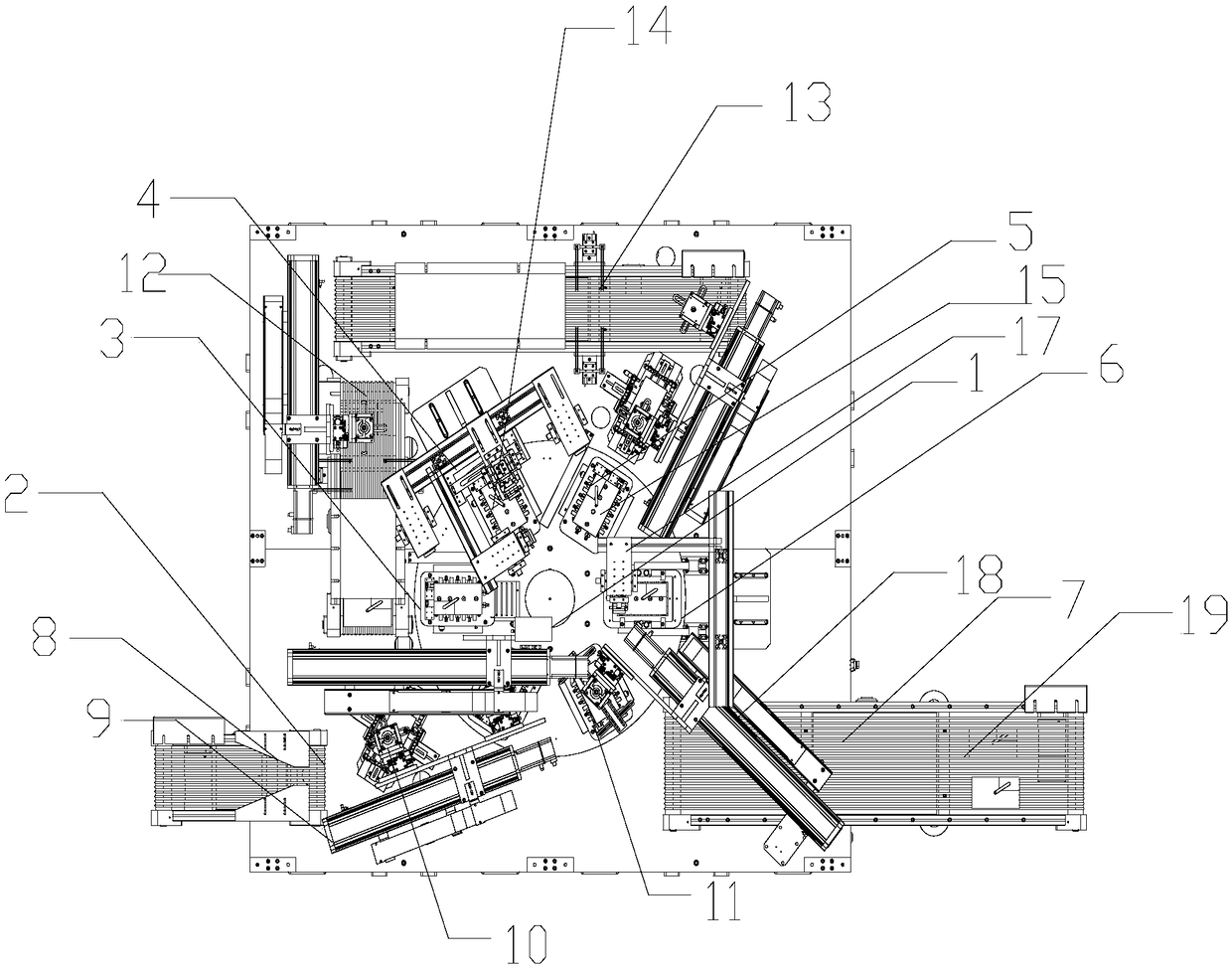

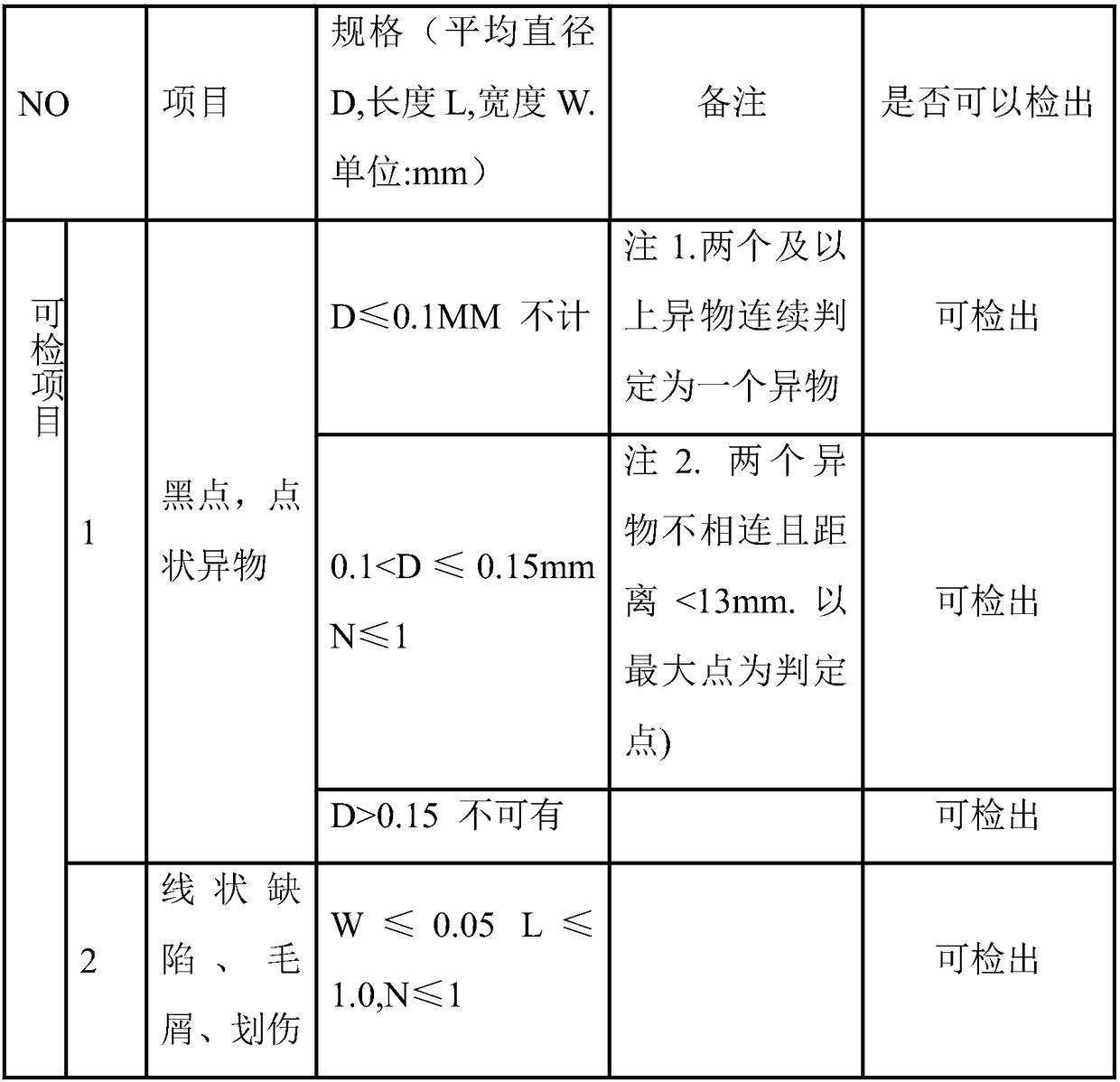

[0044] The invention provides a detection method of a fully automatic backlight module detection machine, comprising step S1: receiving incoming material information through an optical fiber sensing mechanism and correcting it; step S2: grabbing the corrected incoming material to a jig; step S3 : The film tearing action is carried out through the film tearing mechanism and transported to the lamination correction position through the film conveying line, which specifically includes: the Z axis descends after the turntable mechanism is rotated in place, and then the protective film is clamped by the film clamping cylinder, and the Z axis and the X axis Cooperate with the film tearing action; step S4: start signal acquisition according to the detection signal, including image acquisition, positioning, calculation, output results, and recording data, specifically including: after the turntable mechanism is rotated in place, the light cylinder is pressed down, and the pressure is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com