Joint elbow type lifting device of screen plate frame fixing rack

A technology of lifting device and fixing frame, which is applied in the direction of screen printing machine, rotary printing machine, printing, etc., which can solve the problems of large design space, easy vibration, workpiece displacement, and impact vibration can not be effectively eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

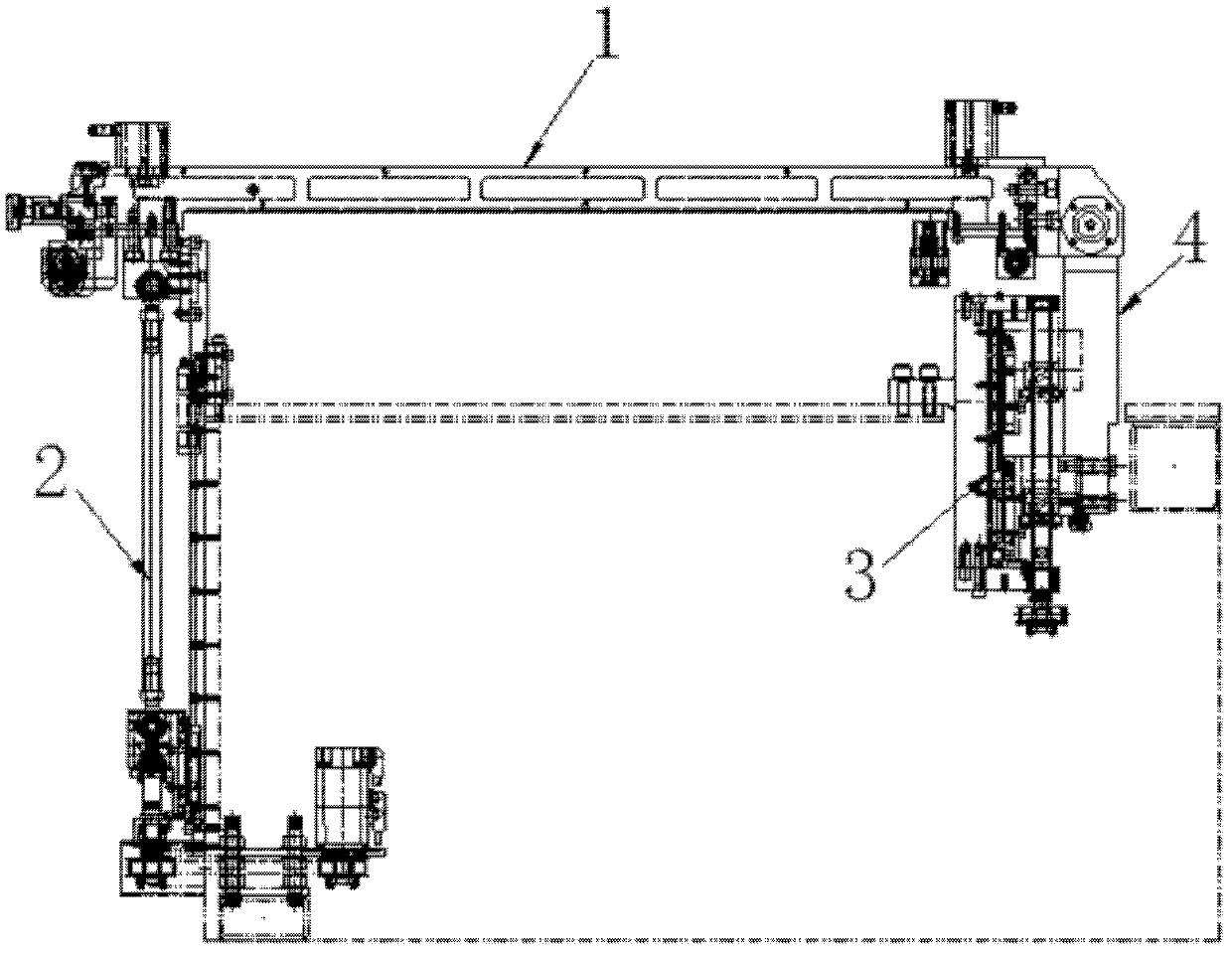

[0012] Embodiment: a joint elbow type screen frame fixing frame lifting device, including a screen frame fixing frame 1 capable of fixing the screen, a front lifting mechanism 2 arranged under the front end of the screen frame fixing frame, and a front lifting mechanism 2 arranged on the screen frame fixing frame. The rear lifting mechanism 3 below the rear end of the screen frame fixing frame, the rear lifting mechanism 3 is connected with a vertically arranged traction strut 4 and can drive the traction strut up and down, and the upper end of the traction strut 4 is fixed to the screen frame The rear end of frame 1 is pivotally connected, the front end of the screen frame fixing frame rests on the frame, and the front lifting mechanism can lift the front end of the screen frame fixing frame. Since the rear end of the screen frame fixing frame and the traction strut are pivotally connected with joint elbows, the screen frame fixing frame can rotate around its connection point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com