Low energy consumption anaerobic-oxic coupled membrane bioreactor and sewage treatment method

A bioreactor, coupled membrane technology, used in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The problems of high flow rate and poor denitrification effect can achieve the effect of good denitrification effect and significant energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

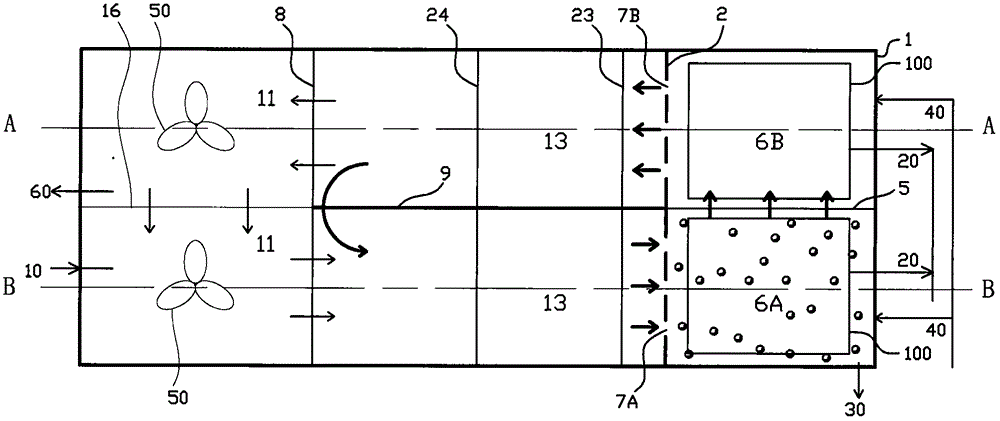

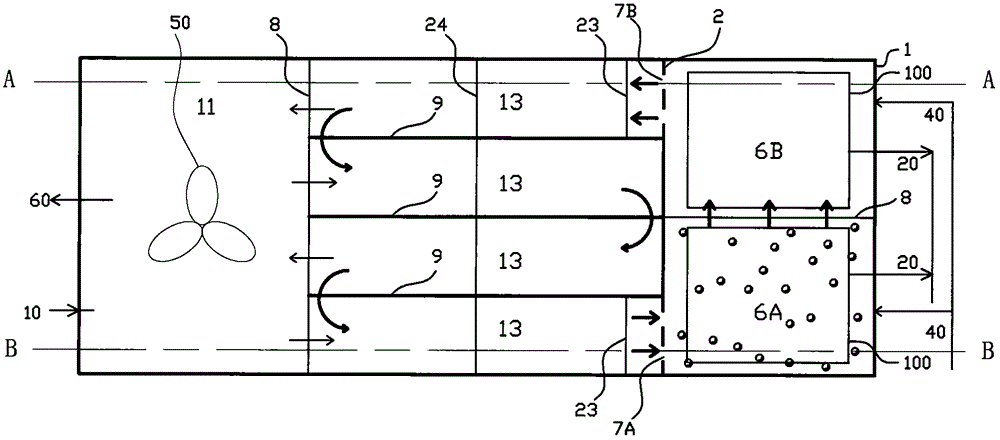

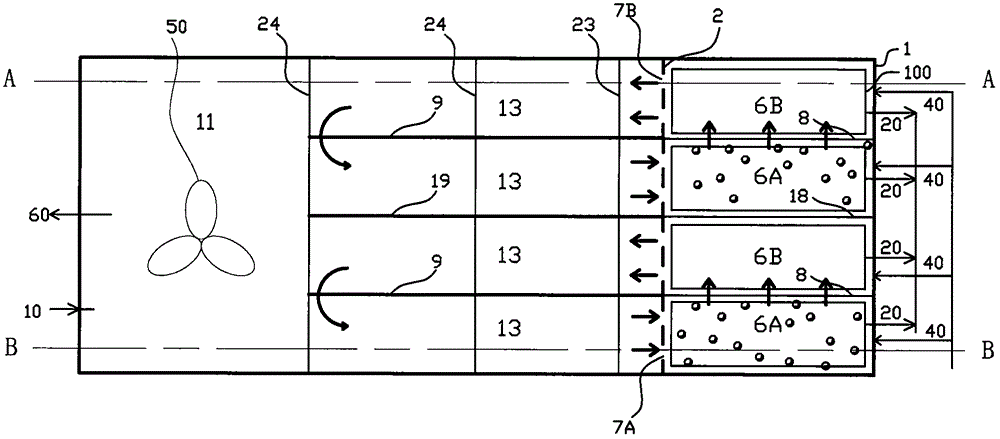

[0035] see Figure 1 to Figure 7 , the first to the fourth low energy consumption coupled membrane bioreactors are characterized in that they include a reaction tank (1), at least one vertical membrane tank partition (2) is arranged in the reaction tank (1), and the membrane tank Partition (2) separates the reaction zone (4) and the membrane tank (6) into which the reaction tank (1) is divided, and at least one horizontal air lift partition (5) is established in the membrane tank (6). The partition (5) divides the membrane pool (6) into equal at least one membrane pool A (6A) and at least one membrane pool B (6B), and the top of the air stripping partition (5) separates the membrane pool A (6A) and the membrane pool Pool B (6B) is connected, and at least one membrane module (100) is provided in the middle of membrane pool A (6A) and membrane pool B (6B); at least one membrane pool channel is provided at the bottom of the membrane pool partition (2) A (7A), which communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com