Patents

Literature

56results about How to "Make full use of production capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

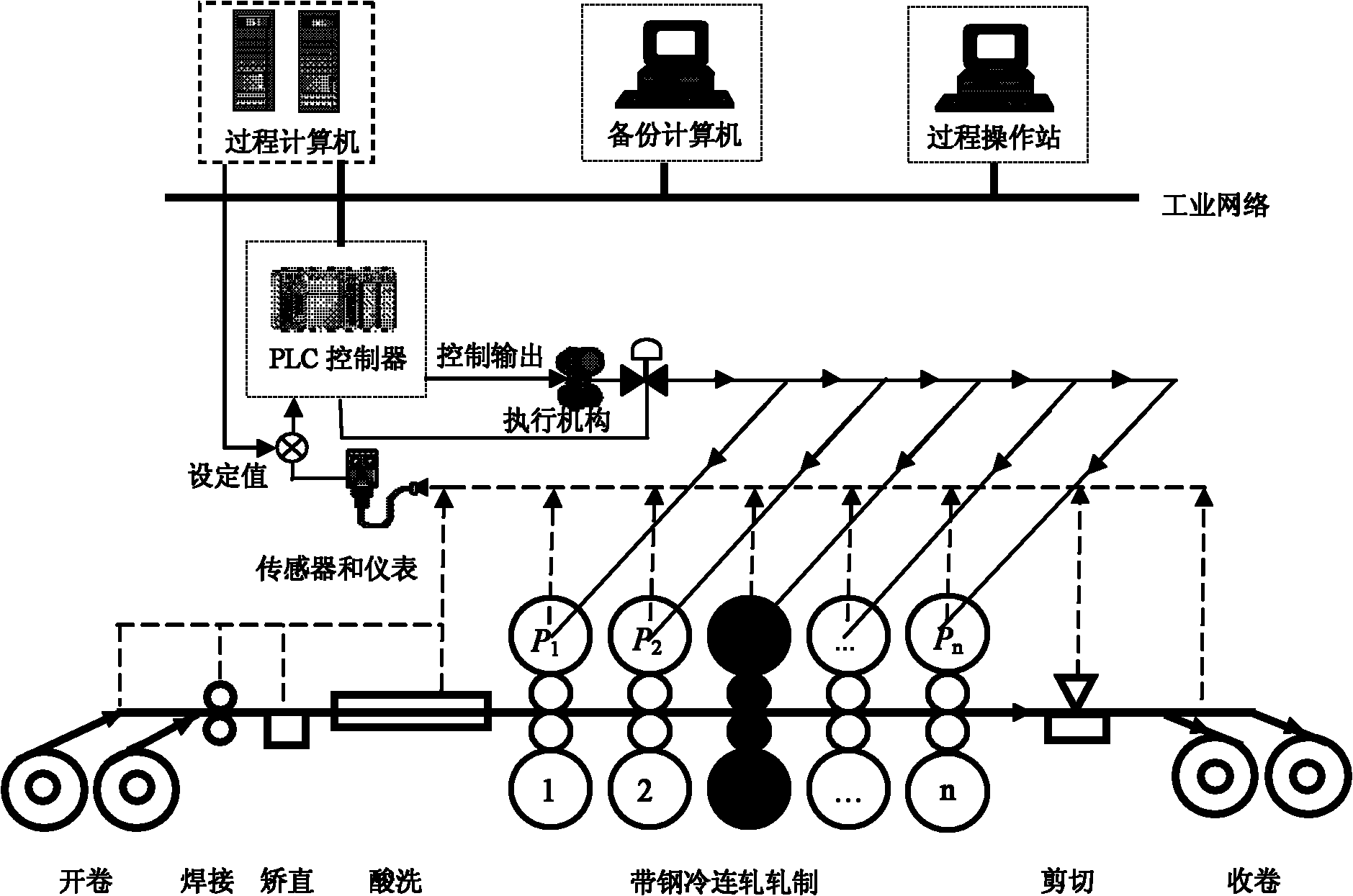

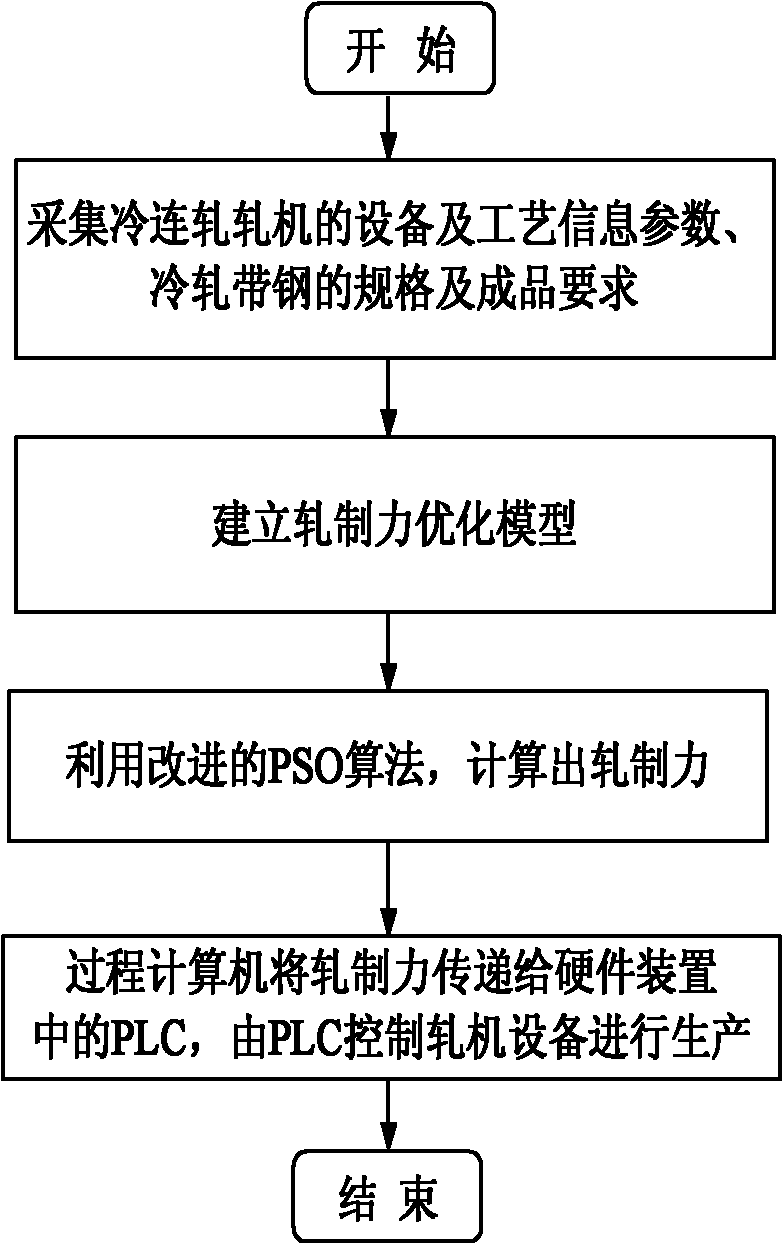

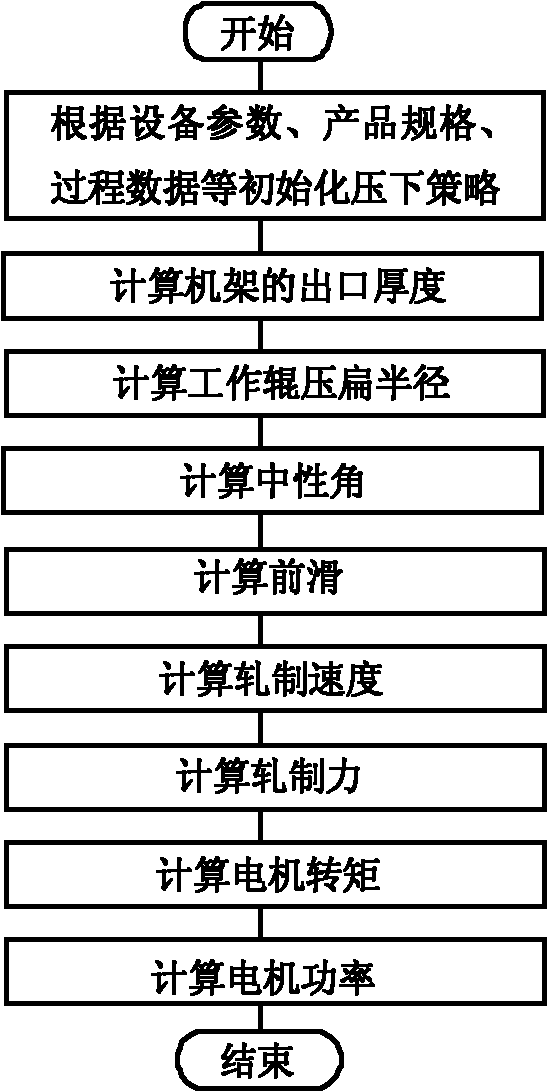

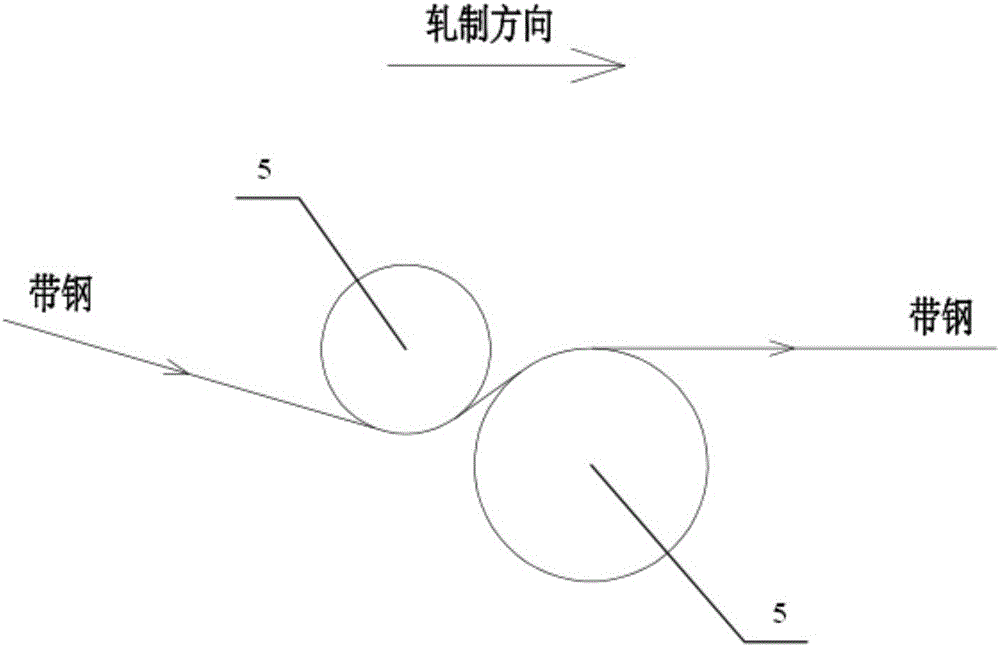

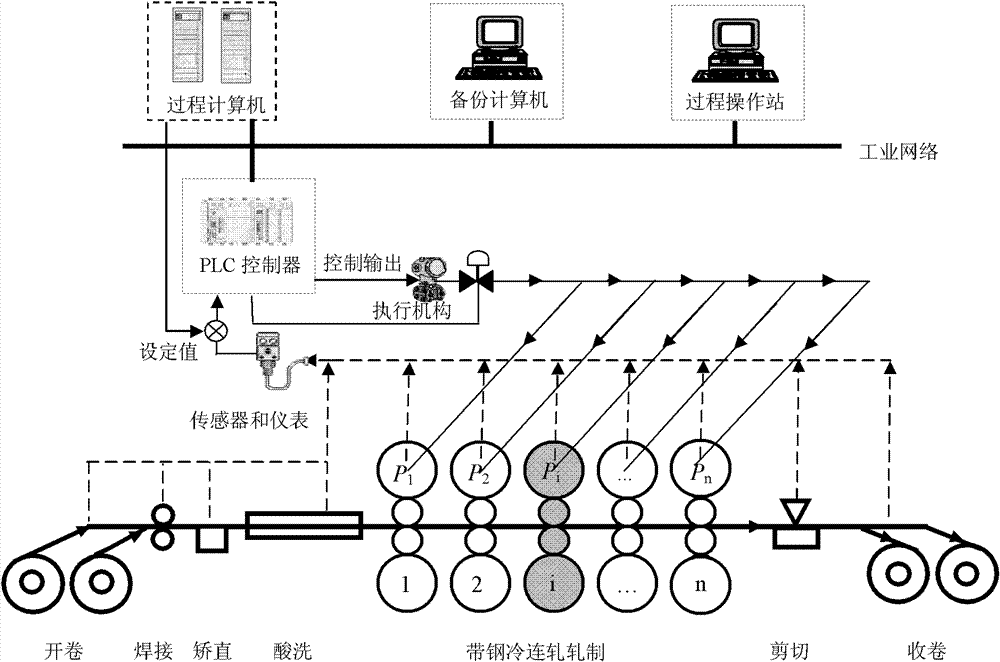

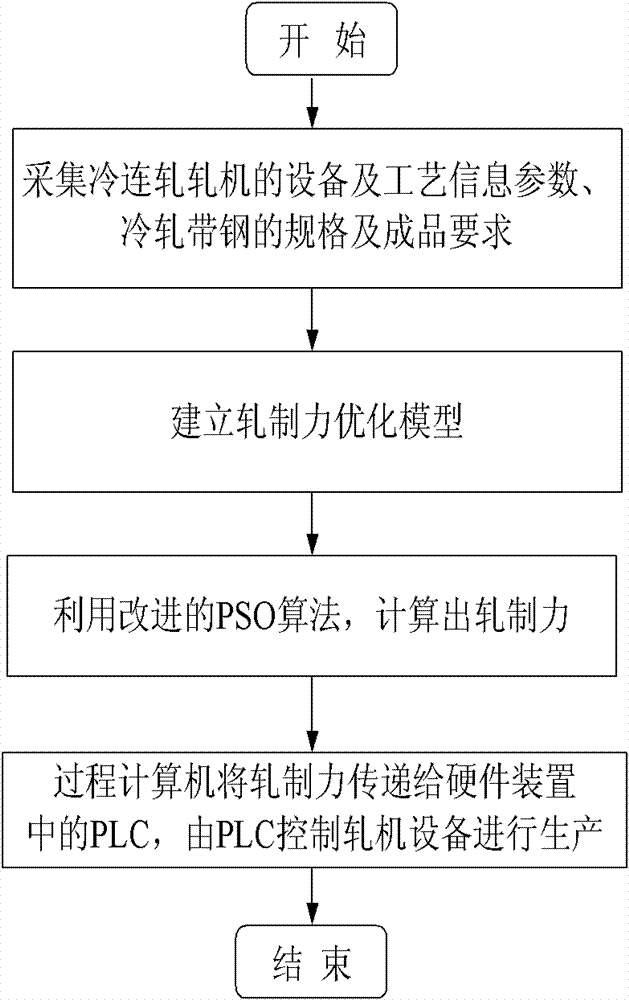

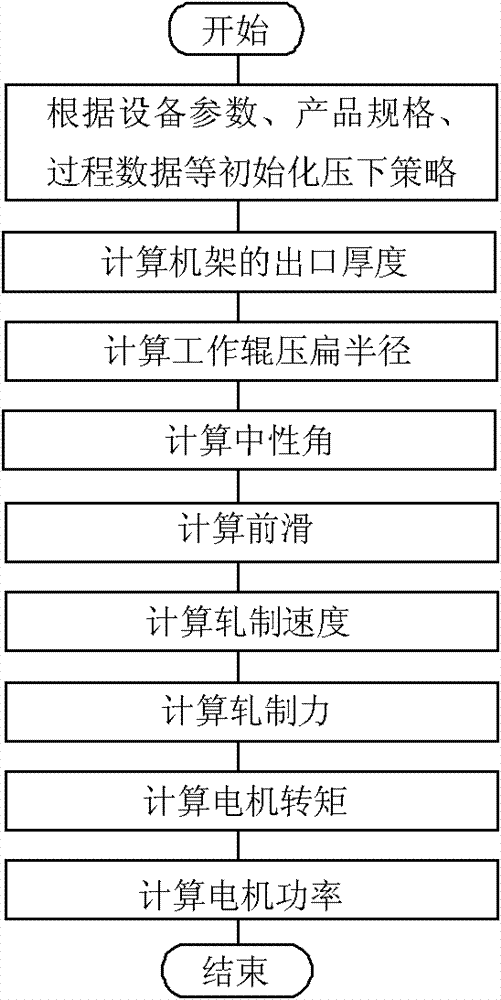

Rolling method and device for strip steel tandem cold rolling

ActiveCN102513351AQuick calculationMake full use of production capacityMeasuring devicesTension/compression control deviceElectric machineryStrip steel

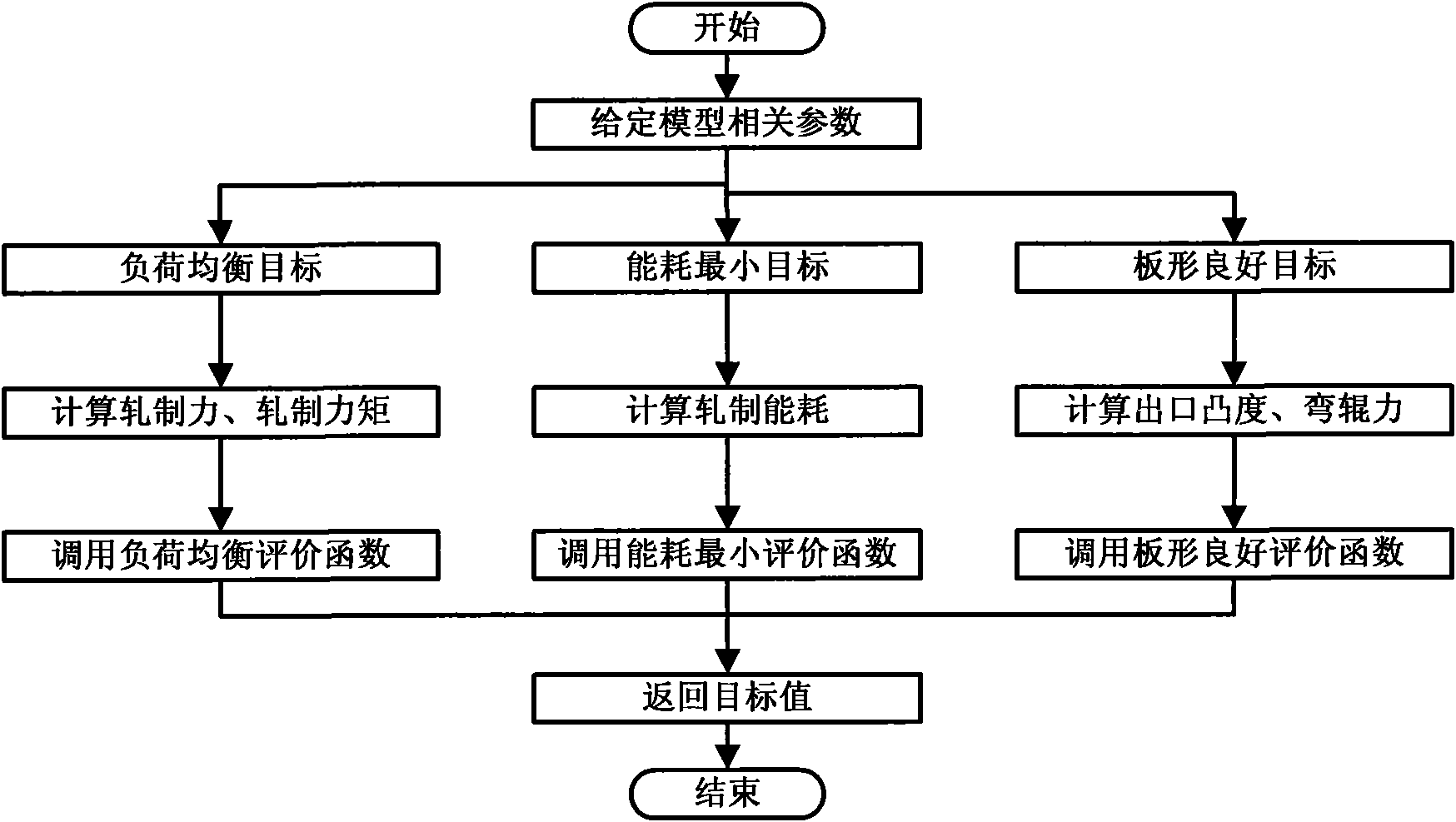

A rolling method and a device for strip steel tandem cold rolling belong to the technical field of metallurgical process control. Based on site conditions of the strip steel tandem cold rolling practical production, the rolling method and the device for the strip steel tandem cold rolling fully consider reasonability of optimization calculation of rolling force, select lowest energy consumption as an optimization goal, adopt a large number of constraint conditions in the practical rolling production process, utilize an improved particle swarm optimization (PSO) optimization algorithm to carry out optimal calculation on the basis of rolling mechanism relationship, and can quickly calculate out optimized rolling schedule information to avoid extra cost caused by lack of comprehensive consideration of experience rules. By means of the rolling method and the device for the strip steel tandem cold rolling, full play to the production capacity of the whole tandem cold rolling system can be given, product quality is improved, total power of a motor of a rolling mill is reduced simultaneously, and energy saving and consumption reduction are achieved accordingly.

Owner:NORTHEASTERN UNIV

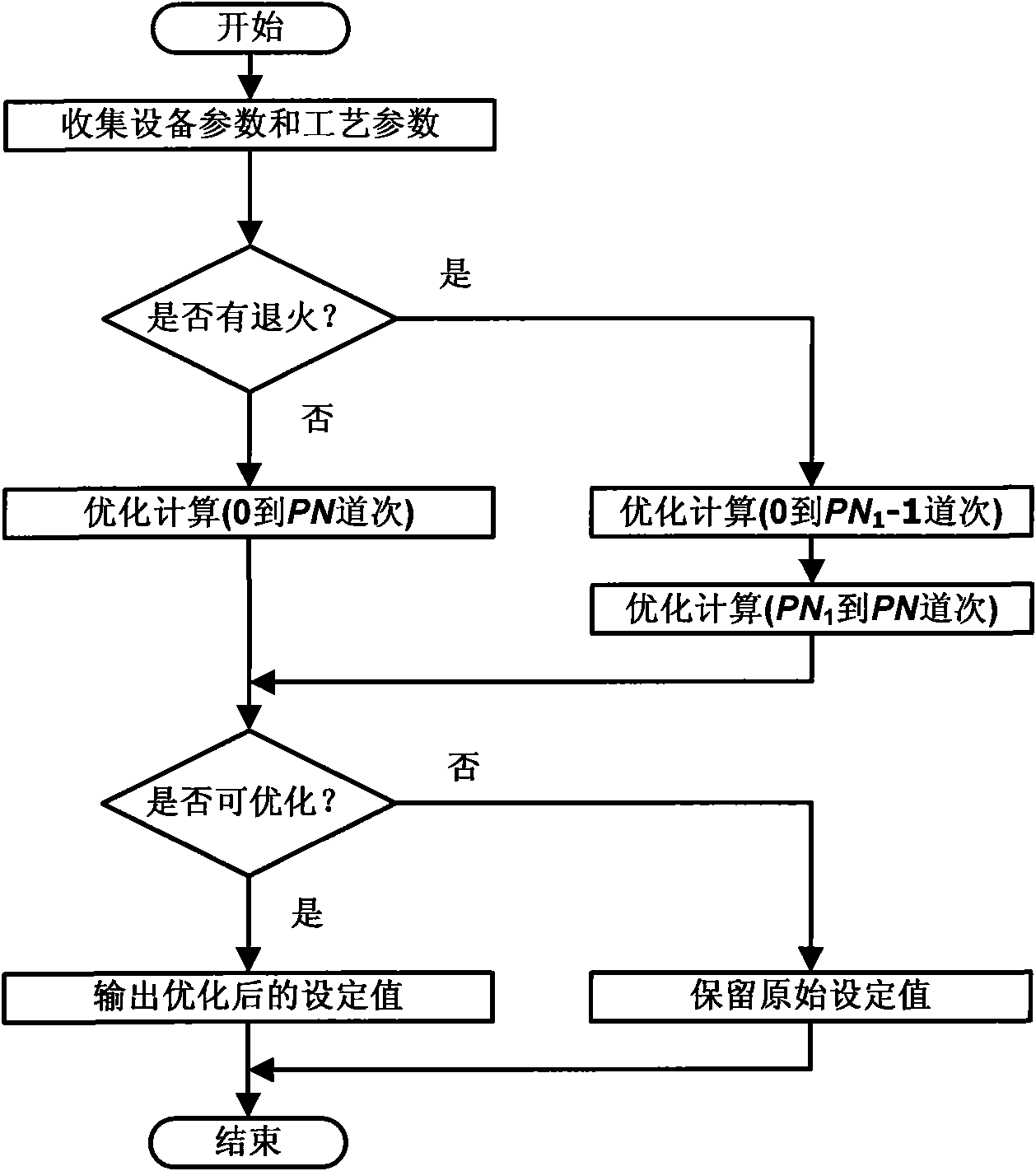

Optimization method of rolling schedule of non-reversible aluminum strip cold rolling mill

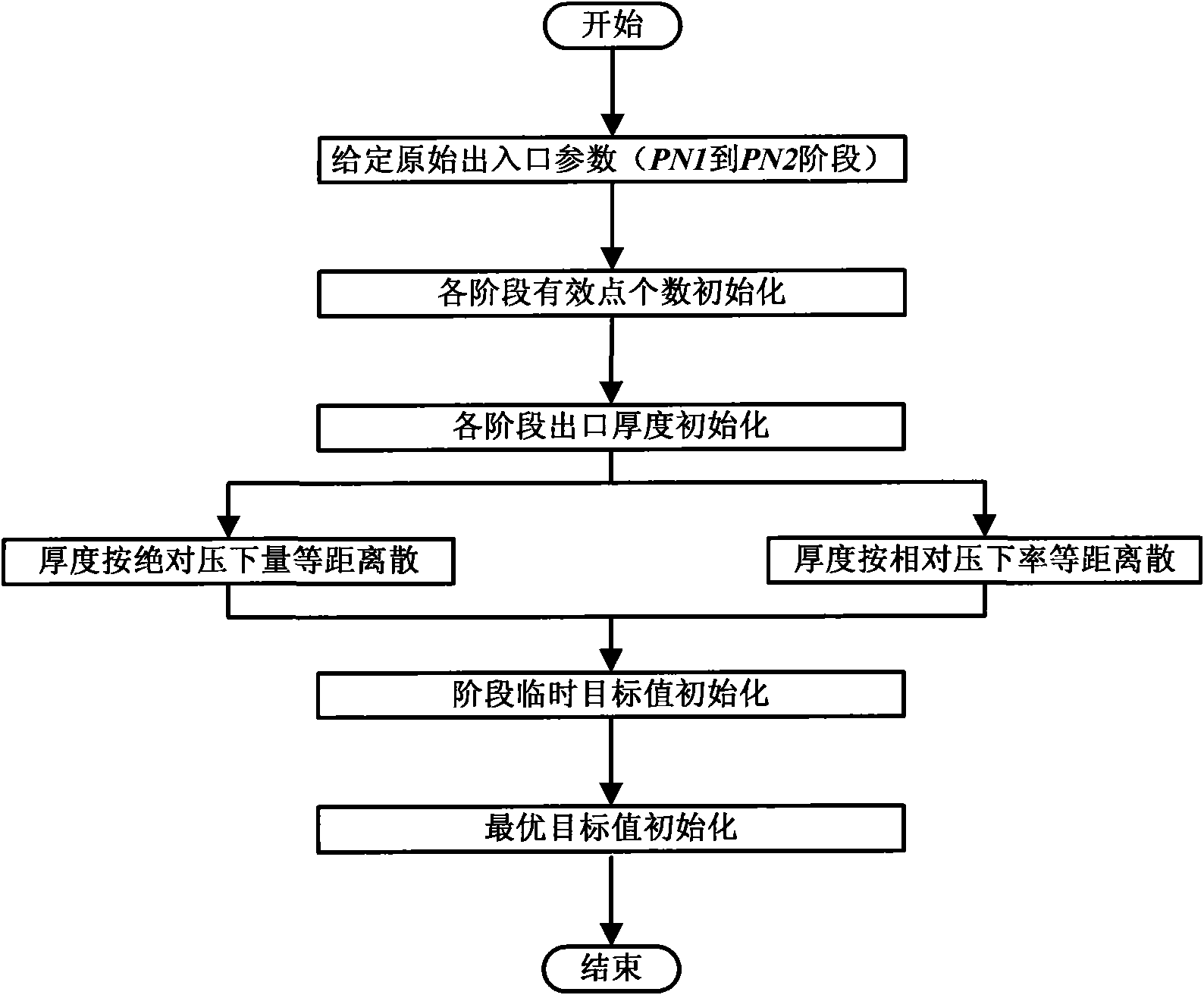

InactiveCN101658871AReduce in quantityMake full use of production capacityRoll mill control devicesMetal rolling arrangementsRational useDiscretization

The invention relates to an optimization method of the rolling schedule of a non-reversible aluminum strip cold rolling mill, which comprises the following steps: (1) collecting the equipment parameters and the technological conditions of the aluminum strip cold rolling mill; (2) determining the specification of strips and the requirements on finished products; (3) collecting the related parameters of the actual using schedule; (4) determining the optimization targets; (5) carrying out discretization and initialization on the thickness of an outlet; (6) calling an optimization and calculationsubprogram according to the annealing stage; and (7) completing the optimization calculation of the schedule. The optimization method takes full consideration of the reasonableness and the availability of the schedule after optimization and takes the actual application schedule as the optimization basis; the optimization method proposes the new target form of three optimization targets of load balance, minimum energy consumption and good strip shape; and the optimization method takes the consideration of the static constrains and the dynamic constraints in actual rolling during the optimization process, thereby improving the dynamic optimization algorithm, reducing the calculation amount and realizing the fast calculation. The optimization method fully plays the production capacity of therolling mill, thereby ensuring the reasonable use of equipment, leading the strip shape of the products to be good, reducing the energy consumption and being applicable to the online use.

Owner:苏州有色金属研究院有限公司

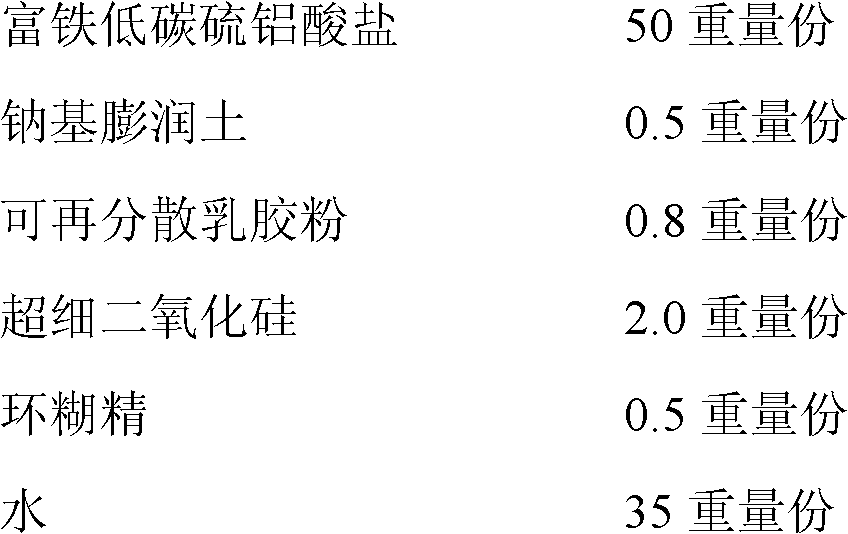

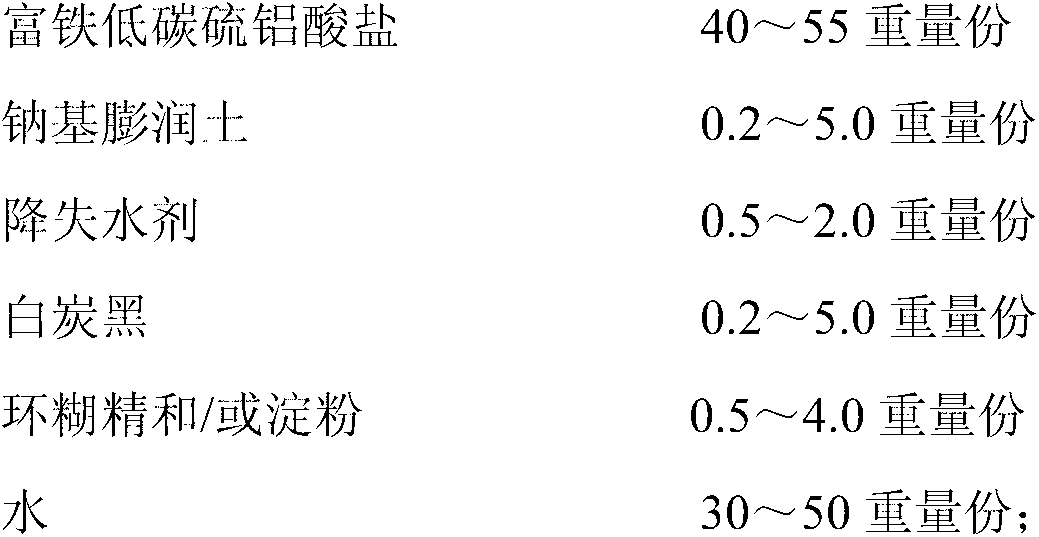

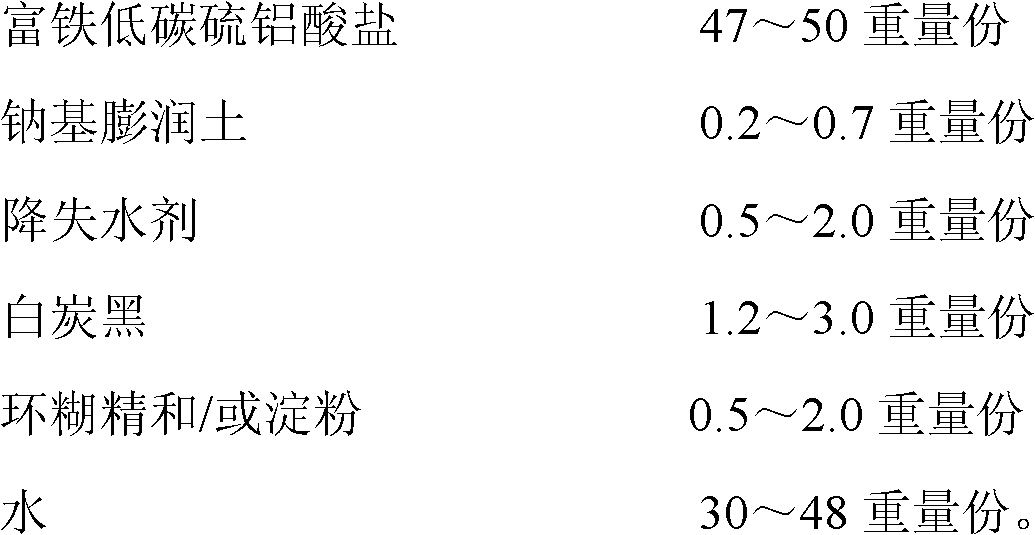

Thixotropic chemical sealing channeling agent

ActiveCN102181274AFormation damage is smallImprove construction safetyDrilling compositionSealing/packingChemistryCarbon black

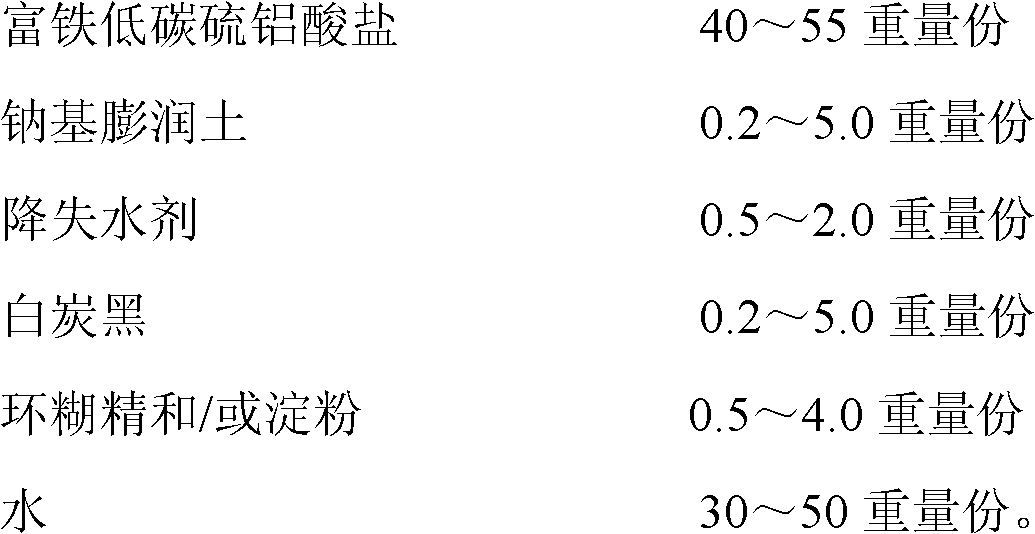

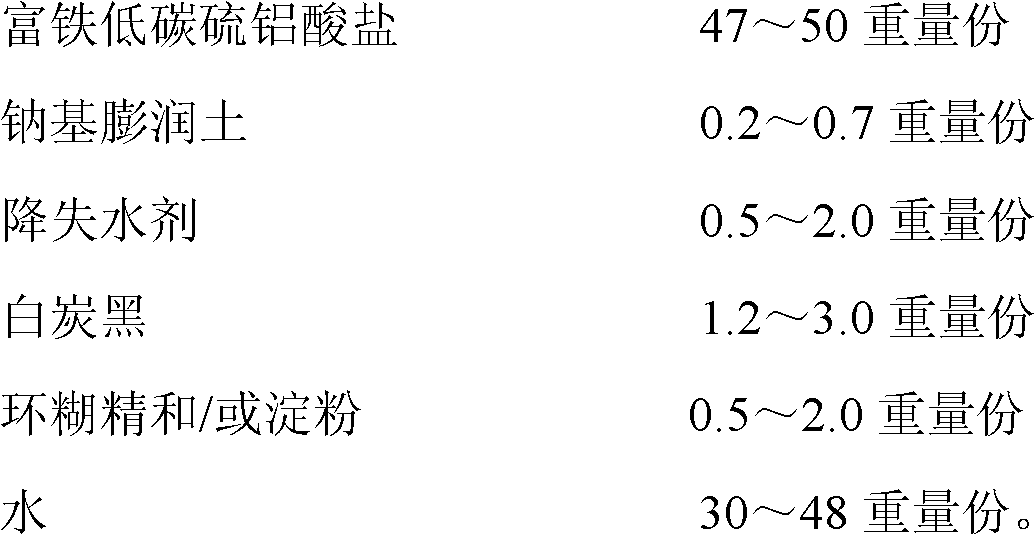

The invention provides a thixotropic chemical sealing channeling agent. The sealing channeling agent comprises the following raw materials: 40 to 55 weight parts of iron rich low-carbon sulfur aluminate, 0.2 to 5.0 weight parts of sodium-based bentonite, 0.5 to 2.0 weight parts of fluid loss agent, 0.2 to 5.0 weight parts of white carbon black, 0.5 to 4.0 weight parts of cyclodextrin and / or starch and 30 to 50 weight parts of water. The chemical sealing channeling agent has the characteristics of strong adhesion and thermal stability, good durability, prominent cracking resistance and the like; the linear expansion rate reaches over 0.2 percent, the compressive strength reaches over 30MPa, and the shearing strength reaches over 10MPa; and by adding dispersant, fluid loss agent and thixotropic regulator, the sealing channeling agent has high thixotropic property and loss resistance.

Owner:PETROCHINA CO LTD

Light thermal-insulation ceramic tiles and preparation method thereof

The invention discloses light thermal-insulation ceramic tiles, which are prepared by using the following raw materials in percentage by weight: 60.0 to 90.0 percent of ceramic tile raw material, 2.0 to 10.0 percent of additive, 10 to 20 percent of pore-forming material and 0.01 to 2 percent of foaming agent. The ceramic tiles are light, nonabsorbent, heat-proof, fire retardant, nontoxic, harmless, chemical corrosion resistance and mouldproof. The ceramic tiles have a small conductivity factor, stable performance and high mechanical strength. The ceramic tiles are low in cost, simple in process, convenient and quick in construction and good in decoration effect.

Owner:北京盛康宁科技开发有限公司

Earth pond artificial propagation and breeding integrated technology for crayfishes

InactiveCN105360030AQuality assuranceGuaranteed quantityPisciculture and aquariaPrawnEconomic benefits

The invention discloses an earth pond artificial propagation and breeding integrated technology for crayfishes. The earth pond artificial propagation and breeding integrated technology is characterized in that propagation and breeding are carried out in the same pond, so that both two seasons of juvenile crayfishes and two seasons of adult crayfishes can be harvested in one pond, and therefore, two seasons of juvenile crayfishes and one season of adult crayfishes are additionally harvested in comparison with crayfishes harvested by using a conventional pond breeding mode of crayfishes. According to the technical scheme adopted by the invention, the earth pond artificial propagation and breeding integrated technology for crayfishes comprises the following steps: (I) creating and modifying pond conditions; (II) preparing the pond; (III) feeding parent crayfishes; (IV) feeding the crayfishes and applying fertilizer; (V) enabling spawning, hatching and larva growing; (VI) carrying out breeding management; (VII) cultivating juvenile crayfishes; (VIII) breeding adult crayfishes; and (IX) catching adult crayfishes. Compared with the conventional pond breeding mode of crayfishes, the earth pond artificial propagation and breeding integrated technology provided by the invention has the beneficial effects that the artificial crayfish propagation is added, so that the quality and quantity of larvae bred in the pond are guaranteed; crayfish finished products come into market in advance; and the yield is increased. Thus, the economic benefits are improved.

Owner:HUBEI LAKER AQUATIC PROD

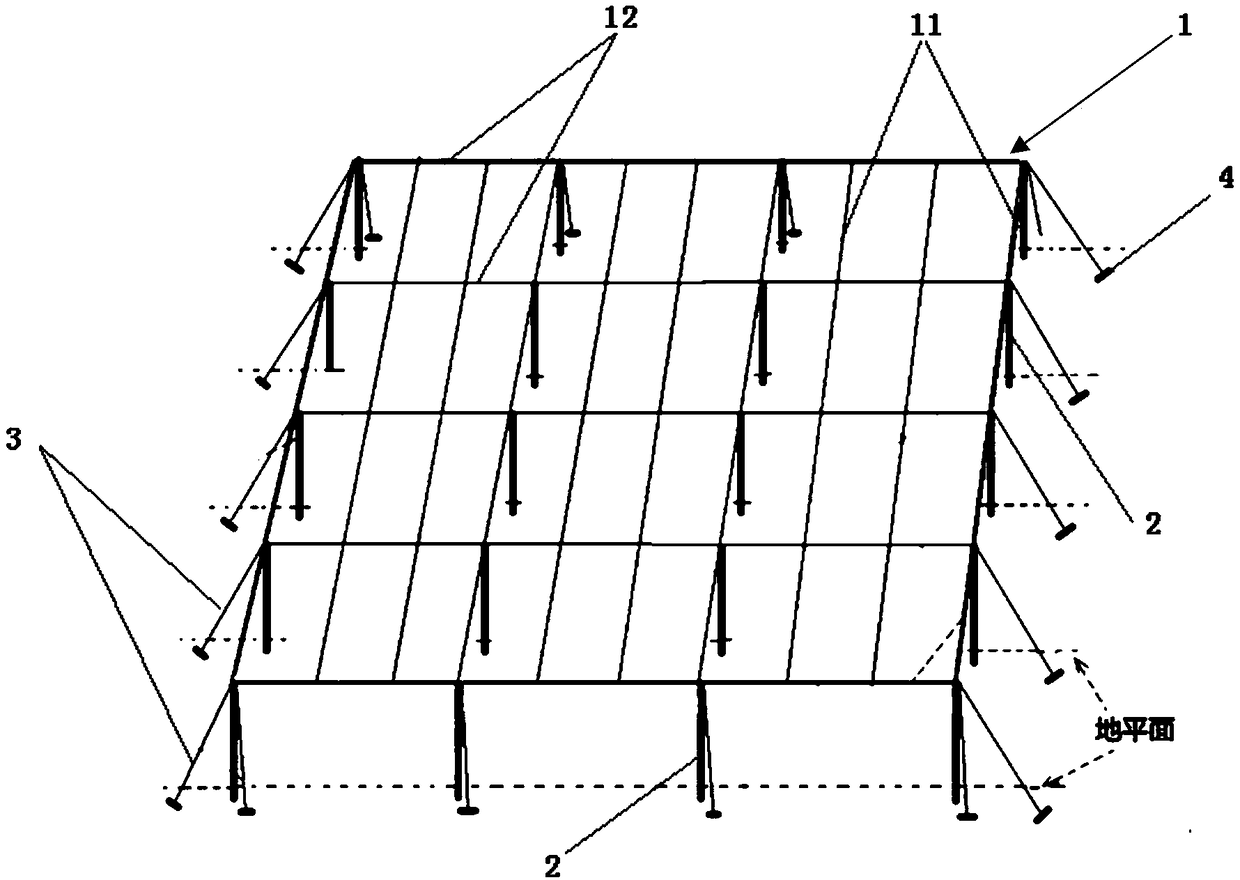

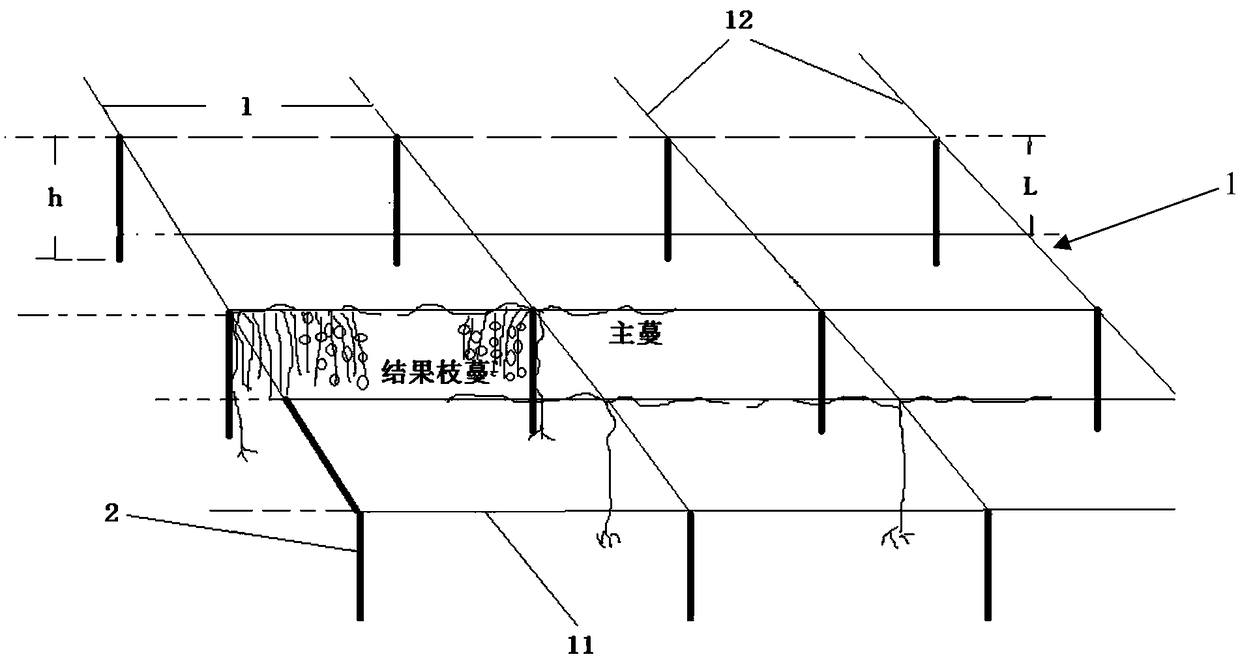

Permeable shelf-shaped cultivation method for passion fruit

ActiveCN109362501AGood light transmissionImprove ventilationPlant supportsFruit crop cultivationFruit setLight energy

The invention discloses a permeable shelf-shaped cultivation method for passion fruits, which comprises the following steps: (1) a permeable shelf-shaped fruit shed is built; (2) the passion fruit seedlings are fixedly planted below the longitudinal beams along the length direction of the longitudinal beams, the planting row spacing is at least 1.3 meters, and the planting spacing is at least 4 meters; (3) before the main trunk of the passion fruits is arranged on the shed frame, the lateral buds are all removed, and only the main buds are reserved for growth; when the main trunk reaches the length of the upper frame, the upper frame is wound on the longitudinal beams, so that the main trunk grows into a main vine along the wiring of the longitudinal beams; (4) combing and pulling down thefruiting branches and vines grown on the main vine to make the fruiting branches naturally droop, and then pruning the fruiting branches according to the growth of the passion fruits and the formation of flower buds to induce the formation of the fruiting branches; (5) pruning the fruiting branches and vines with picked fruits and reduced flower forming capacity; (6) continuously repeating the steps (4) and (5) in the process of planting the passion fruits so as to continuously induce the formation of the new fruiting branches and vines and increase the yield. According to the permeable shelf-shaped cultivation method, the permeability of fruit shed is improved, the utilization rate of light energy is improved, and the yield and quality of the passion fruits are improved.

Owner:广西贺州市正丰现代农业股份有限公司

Control method for preventing deviation of band steel in first-pass rolling procedures

ActiveCN105728473APrevent deviationImprove stabilityRoll force/gap control deviceStrip millSurface roughness

The invention discloses a control method for preventing deviation of band steel in first-pass rolling procedures. The control method includes that the band steel is centered by the aid of a CPC (coil planet centrifuge) device in band steel threading procedures after scrolling is carried out; uncoiling tension on the band steel on a reversible cold rolling mill with small roll diameters and a single framework is higher than reeling tension of pickling units by 20%-45%; reeling tension on the band steel on the reversible cold rolling mill with the small roll diameters and the single framework during first-pass rolling is higher than reeling tension of conventional rolling mills by 10%-20%; inlet turning clamping roll press rolls are positioned at turning locations and are pushed in whole first-pass rolling procedures, and an inlet pressure plate table is in a pushed state; the roughness of the surfaces of rolling mill working rolls is enlarged; first pass rolling is carried out by the aid of high roll bending force; roll gap inclination values are preset for first-pass starting rolling according to intrinsic attributes of rolling mill frameworks. The control method has the advantages that the rolling stability of the rolling mill with the small roll diameters can be improved by the aid of the control method, the probability of deviation breakage accidents can be lowered, and increase of roll consumption due to the deviation breakage accidents can be reduced.

Owner:WISDRI ENG & RES INC LTD

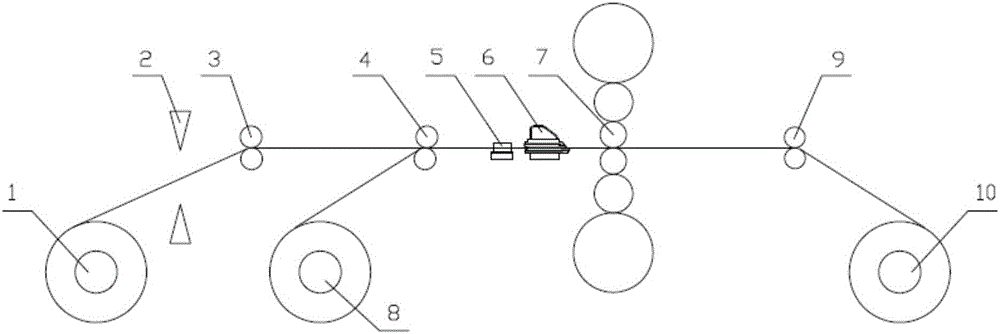

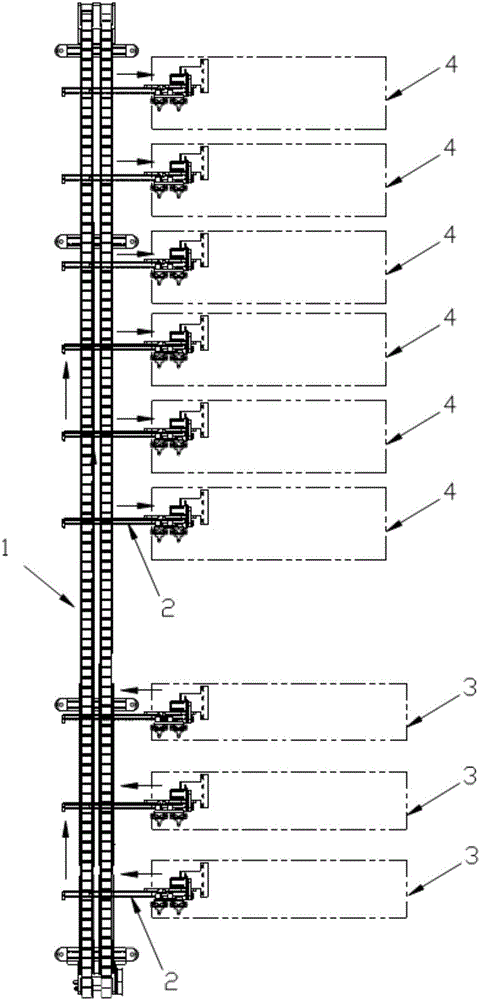

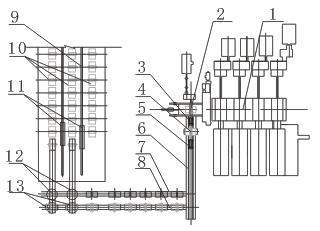

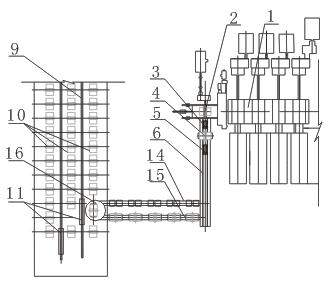

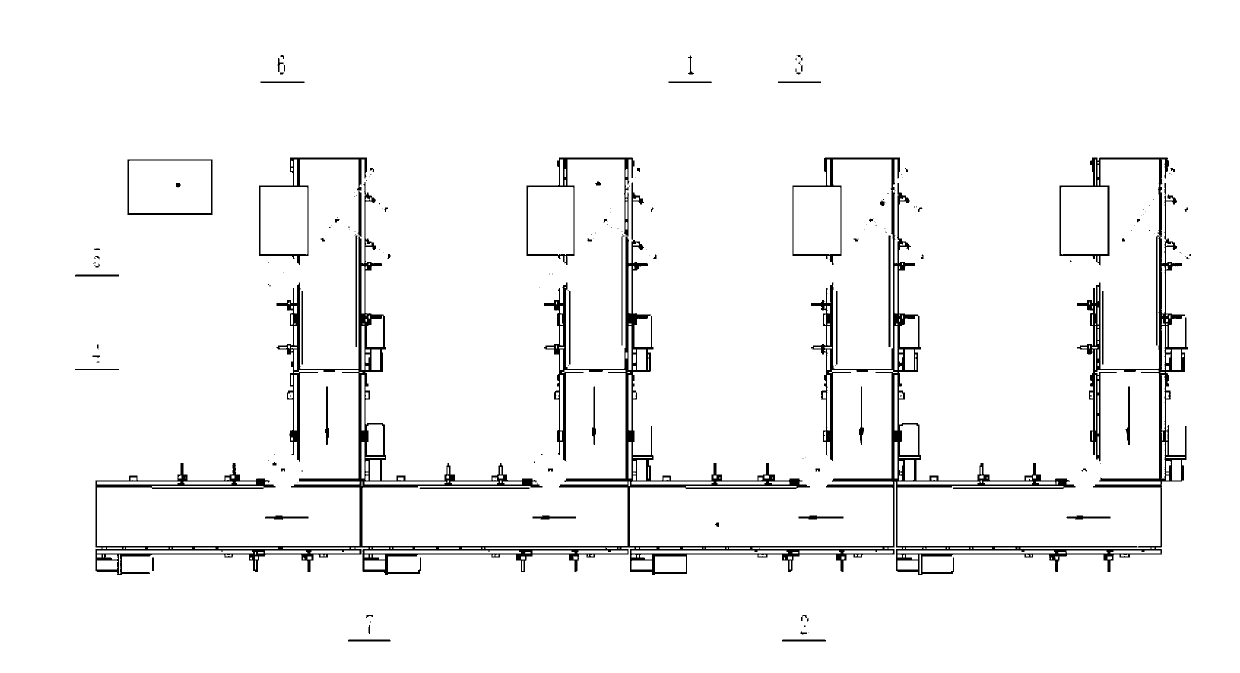

Intelligent card production system and method

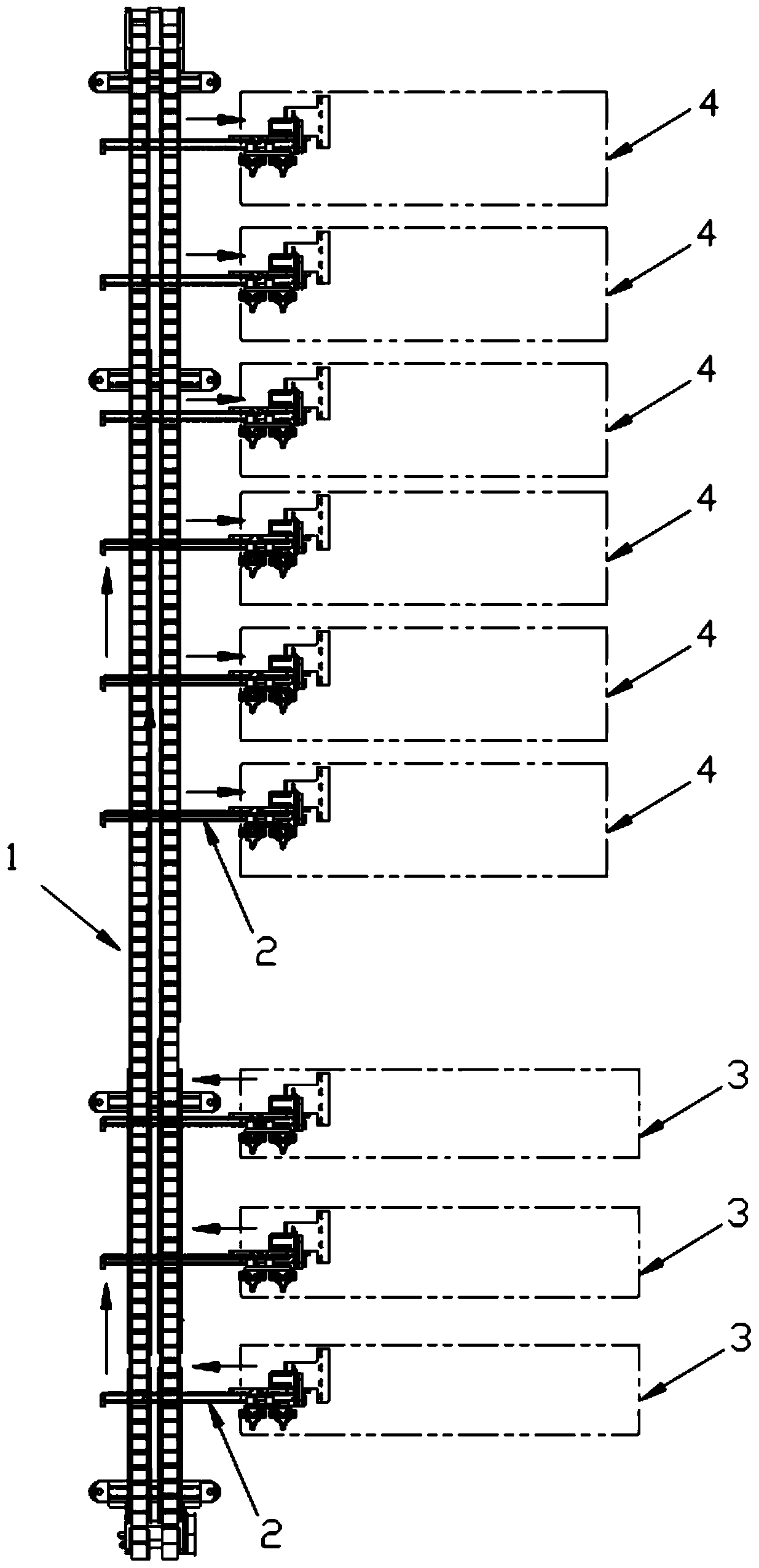

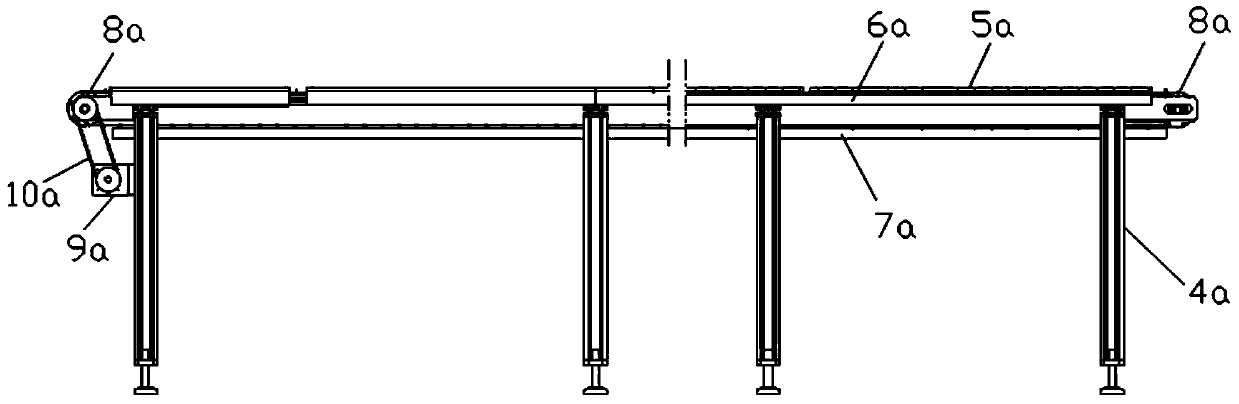

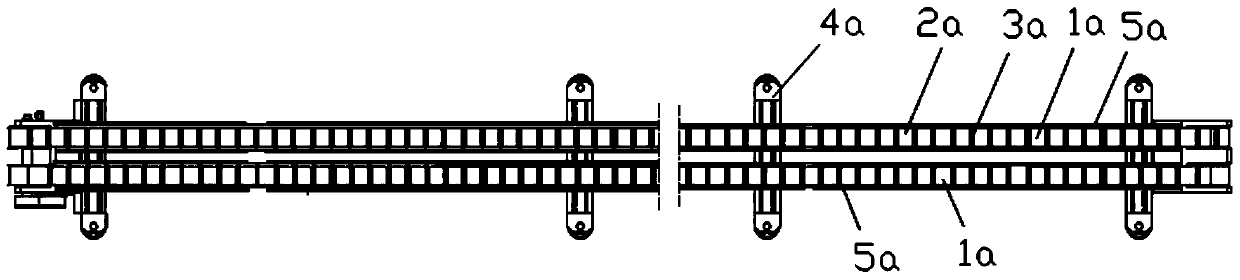

ActiveCN105913115AHigh degree of automationHigh card feeding efficiencyConveying record carriersRecord carriers used with machinesSmart cardEngineering

The invention discloses an intelligent card production system and method. The production system comprises a card conveying total line and a plurality of intelligent card machining devices. The intelligent card machining devices are divided into upstream intelligent card machining devices for conveying cards to the card conveying total line and downstream intelligent card machining devices for obtaining the cards from the card conveying total line. A card carrying device for carrying the cards is arranged between each set of intelligent card machining device and the card conveying total line. The card conveying total line comprises a conveying belt of a closed circulation structure and a power mechanism for driving the circulation operation of the conveying belt. Card seats for accommodating cards are uniformly arranged on the conveying belt along the length direction of the conveying belt. According to the invention, the plurality of intelligent card machining devices and the card conveying total line serving as a link are combined to form the production system, the automatic degree is high, the number of the combined machining devices is not limited, the production efficiency is high, and the whole conveying process of the cards can be tracked.

Owner:GUANGZHOU MINGSEN TECH CO LTD

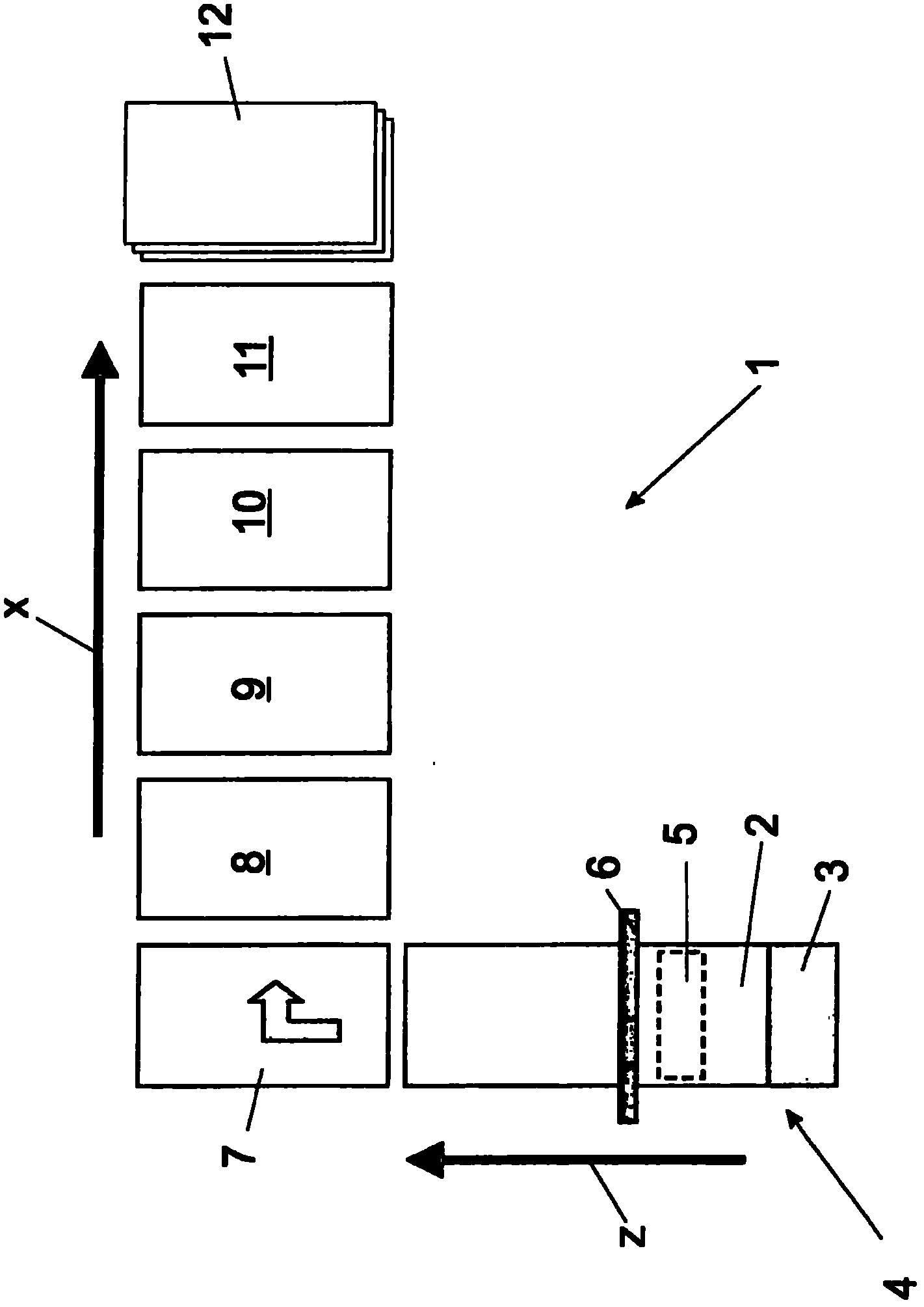

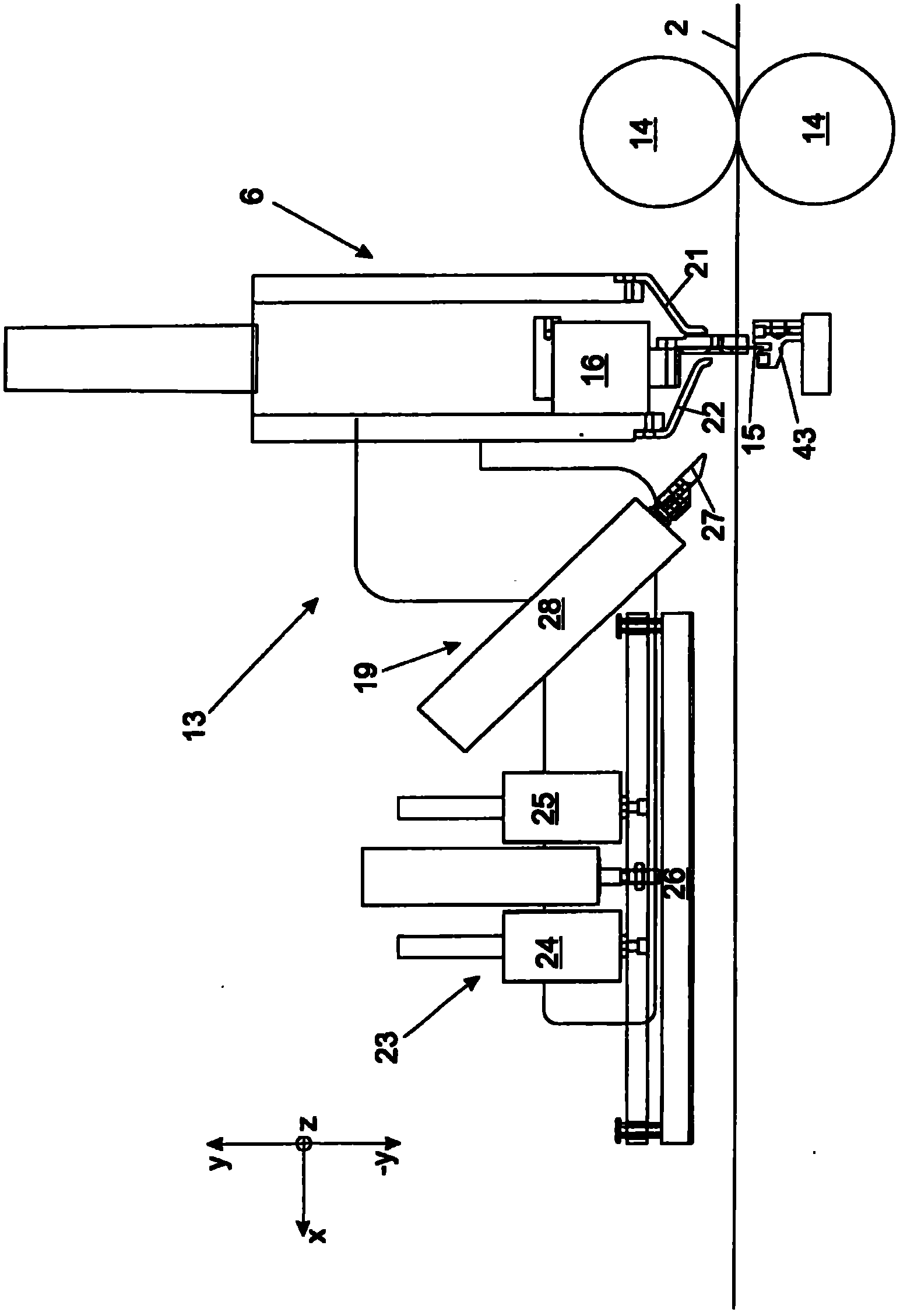

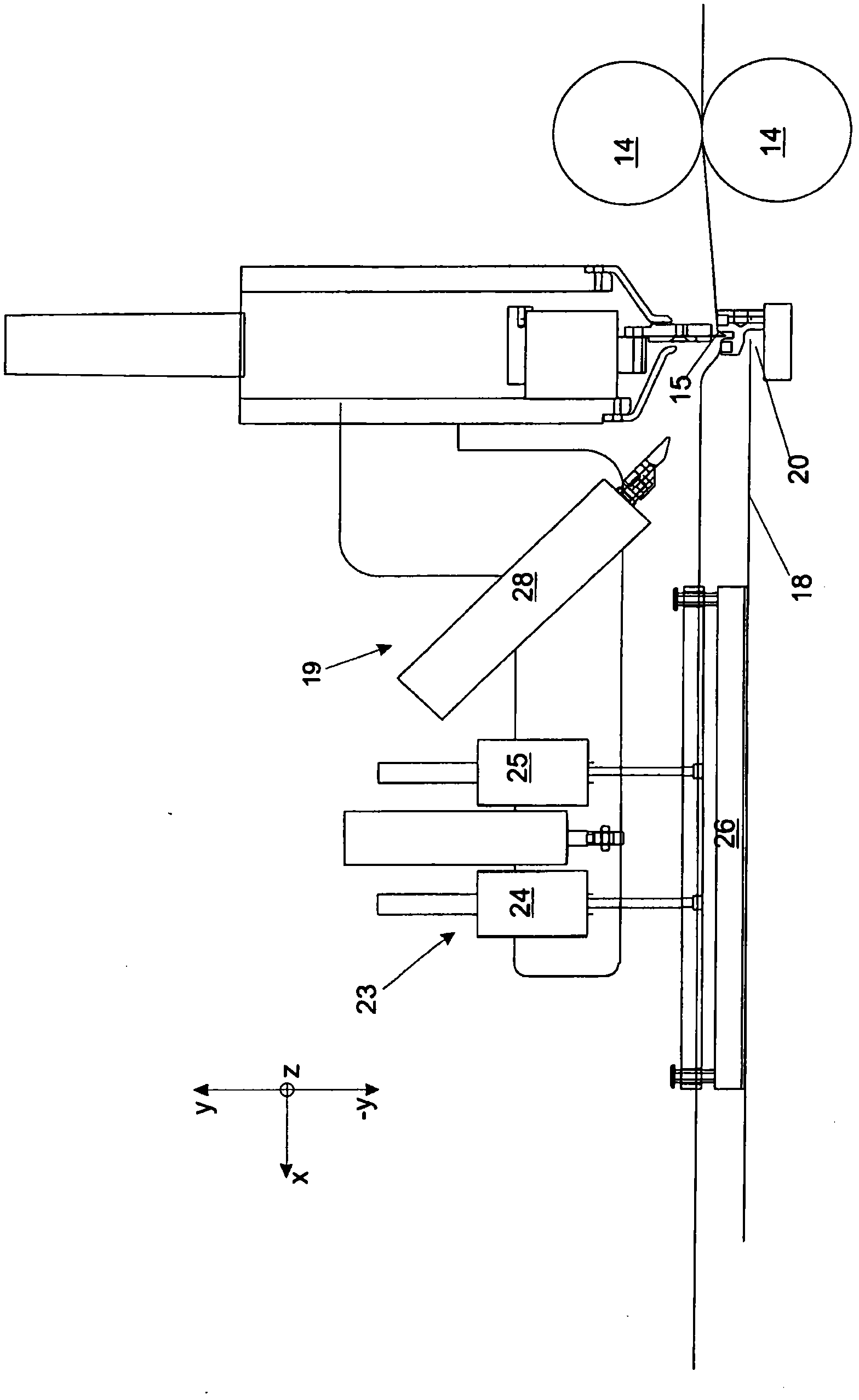

Device and method for producing bags from pieces of tubing

ActiveCN101983166AIncrease spacingTake advantage ofBag making operationsFlexible containers manufactureDriven elementMechanical engineering

The invention relates to a device for producing bags (1) preferably comprising fabric made of stretched strips of plastic and consisting of two layers of material, one over the other. Such a device comprises: an unwinding device (4) from which tubular material or strip-like material, from which a tube can later be made, can be unwound and displaced in the longitudinal direction (z); a detaching device (6) by which means pieces of tubing (18) can be detached from the tubular material (2); and transfer means (42) by which means the individual pieces of tubing supplied in the longitudinal direction can be transferred onto a continuous transversal transport device (x-direction) or taken by said transversal transport device. The transfer means (42) comprise at least one driving element (29) by which means each piece (18) of tubing can be gripped. The at least one driving element (29) can be held at least in the moment of the piece (18) of tubing.

Owner:WINDMOELLER & HOELSCHER GMBH

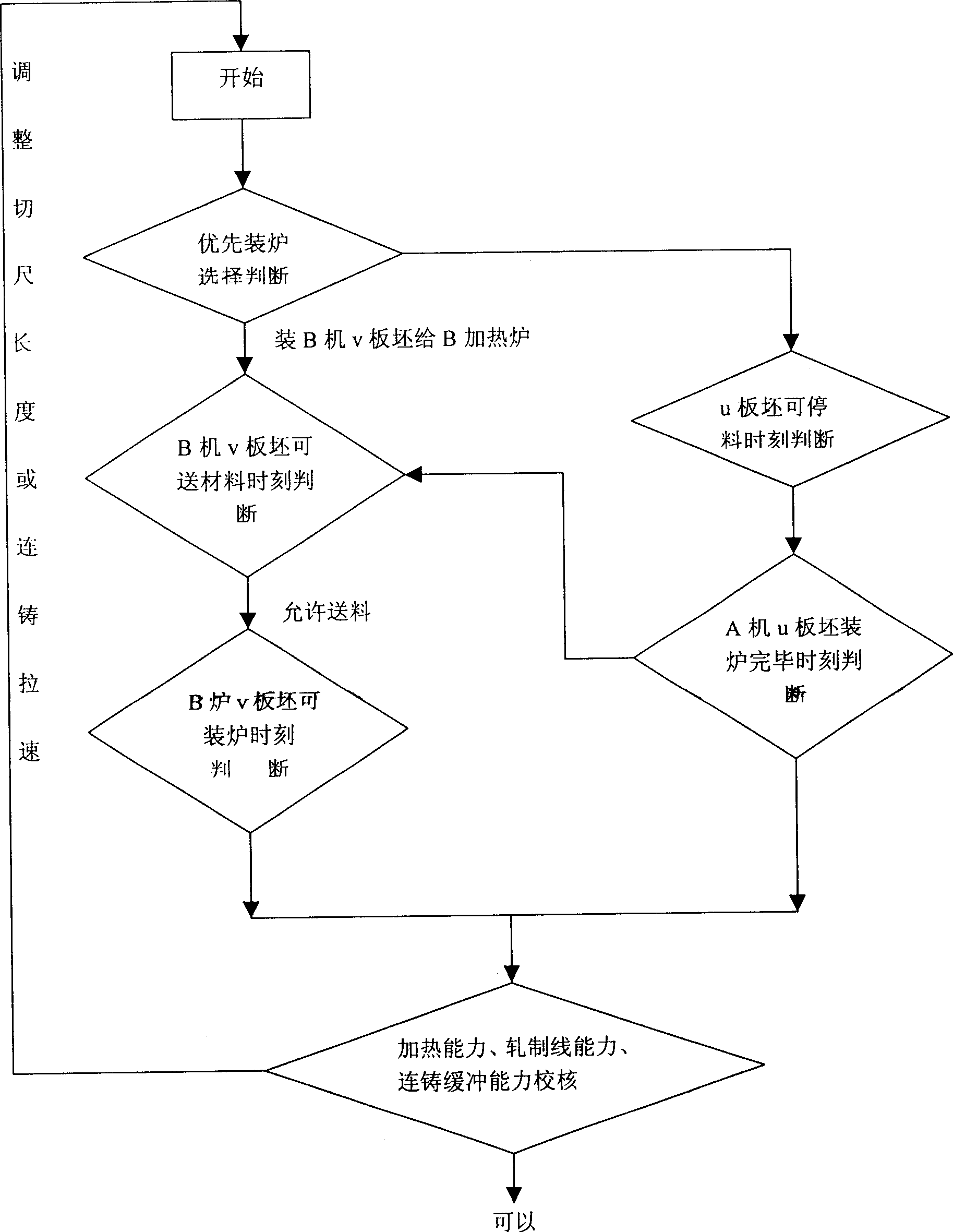

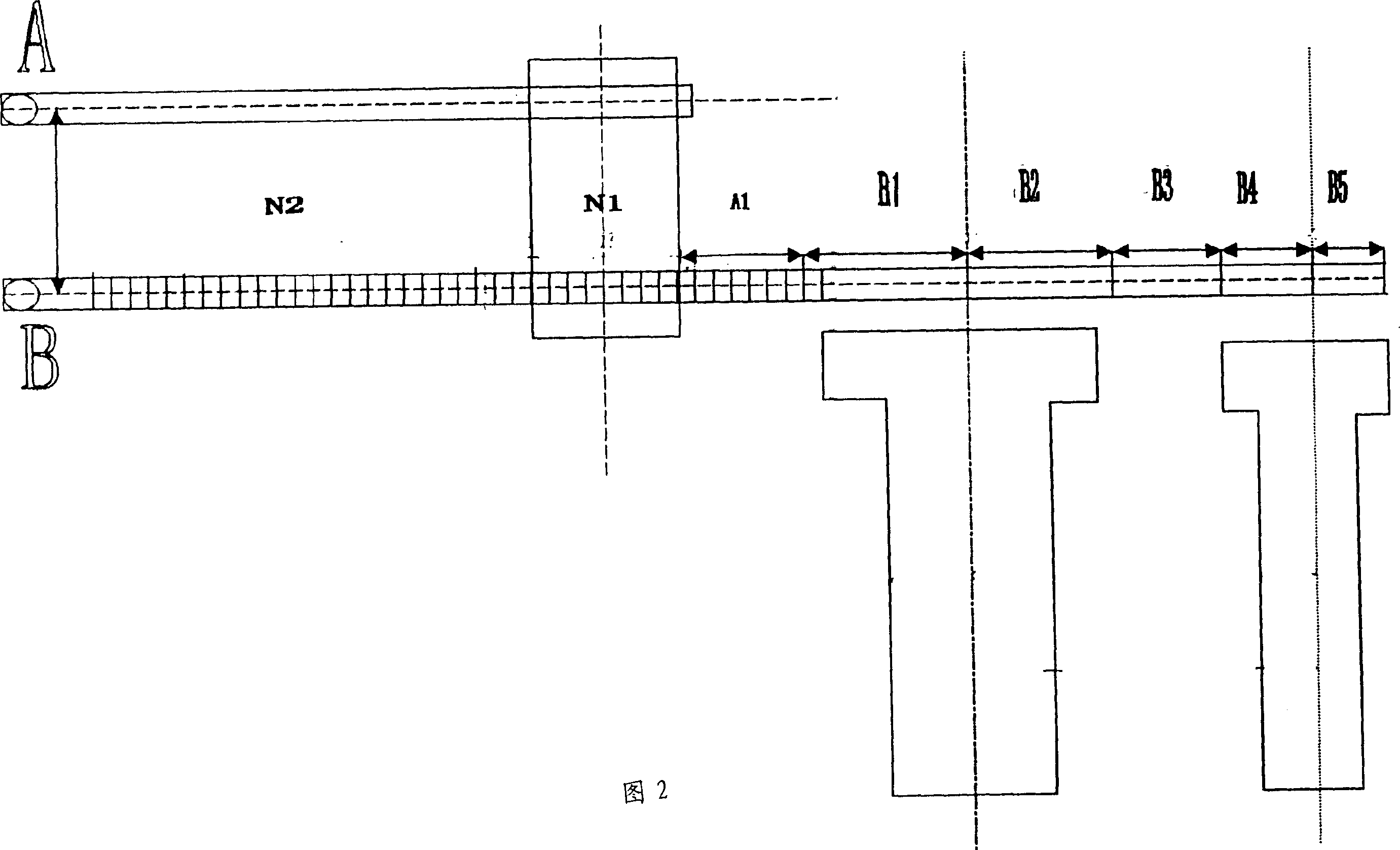

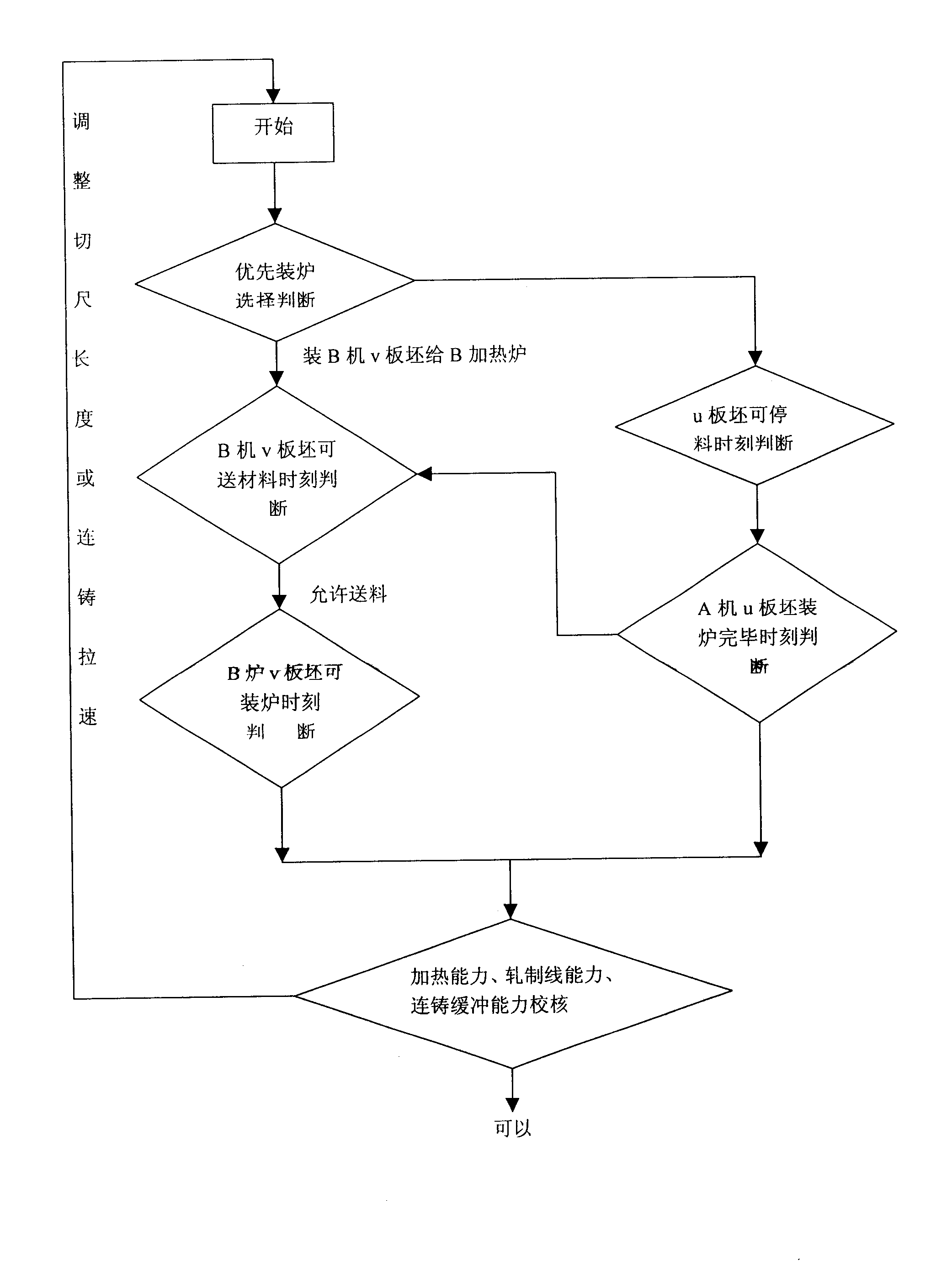

Method for controlling material flos of double-casting machine single roller way double-heating furnace

InactiveCN1483534AMake full use of production capacityEliminate conflictMetal rolling arrangementsProduction lineHeating furnace

The present invention provides a material flow control method for continuous casting and continuous rolling workshop, and is applicable to equipment arrangement mode in which two continuous casting machines are set and their output roller conveyers are combined together, then fed into one heating furnace, and its control method mainly adopts four time comparison: precedence charging time comparison, selecting A casting machine U slab or B casting machine V slab, which can be precedently charged; feeding time comparison of V slab; chargint time comparison of V slab and stripping time comparison after heating. Said invention can implement continuous casting-heating furnace-rolling line semi-rigid connection, and can raise their production capacity.

Owner:ANGANG STEEL CO LTD

Transportation system of hot rolled coil entering high rack warehouse after coil discharge

InactiveCN102431756AReduce storage timeMeet efficiencyStorage devicesProduction lineTransport engineering

The invention discloses a transportation system of a hot rolled coil entering a high rack warehouse after coil discharge, used for transporting the hot rolled coil in a hot-rolled workshop into the high rack warehouse after discharged at the coil discharge position on a coiler. The transportation system is characterized in that the transportation system comprises a coil transportation rail A with a coil transportation trolley and a transportation line, wherein one end of the coil transportation rail A is relatively connected with the coil discharge position of the coiler, the other end of the coil transportation rail A is connected with one end of the transportation line in a matching way, and the other end of the transportation line extends into the high rack warehouse; and the hot rolled coil is transported to the transportation line through the coil transportation trolley along the coil transportation rail after discharged from the coiler and sent into the high rack warehouse through the action of the transportation line. With the adoption of the transportation system, the high rack warehouse is directly butted to a hot-rolled production line without using a mode of crown block hoisting and transportation, thereby the transportation time of warehousing the hot rolled coil is greatly shortened, the transportation system is rapid and has high efficiency, and the safety hidden dangers existing in the hoisting and transportation process of a crown block are also avoided.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

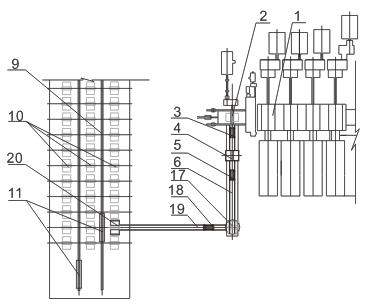

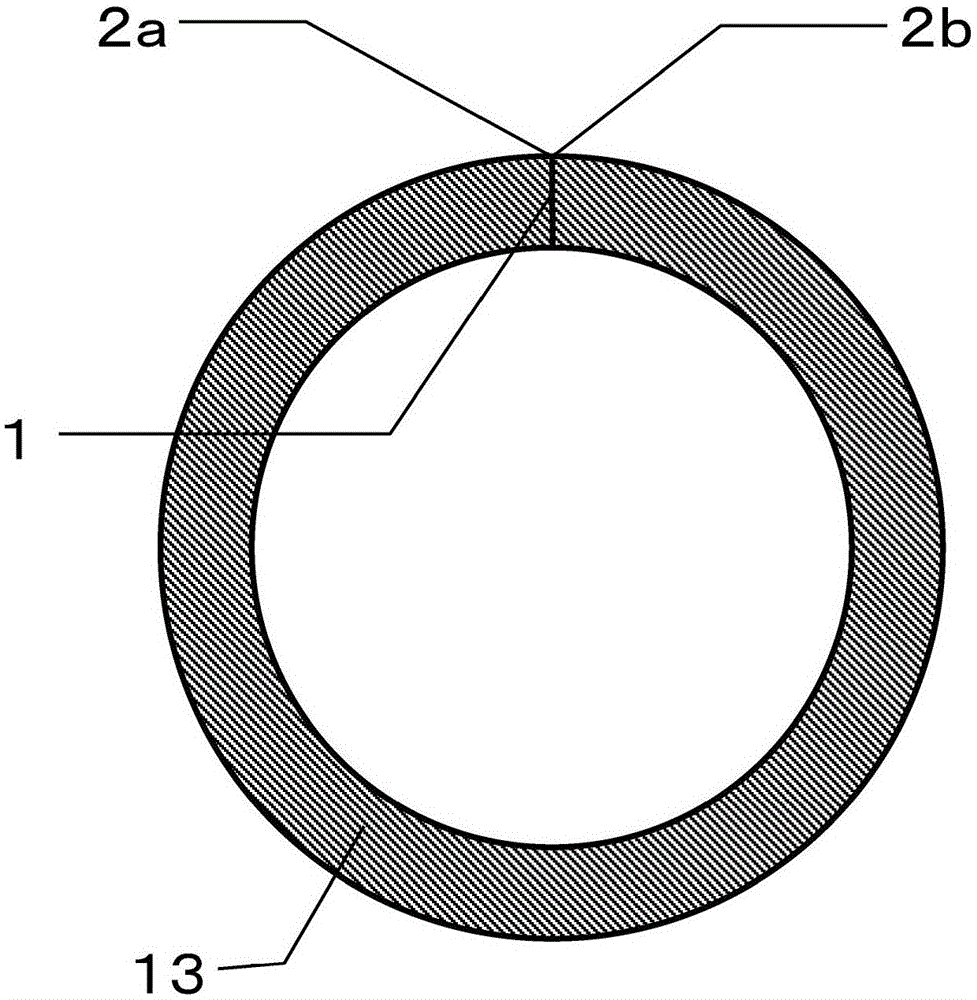

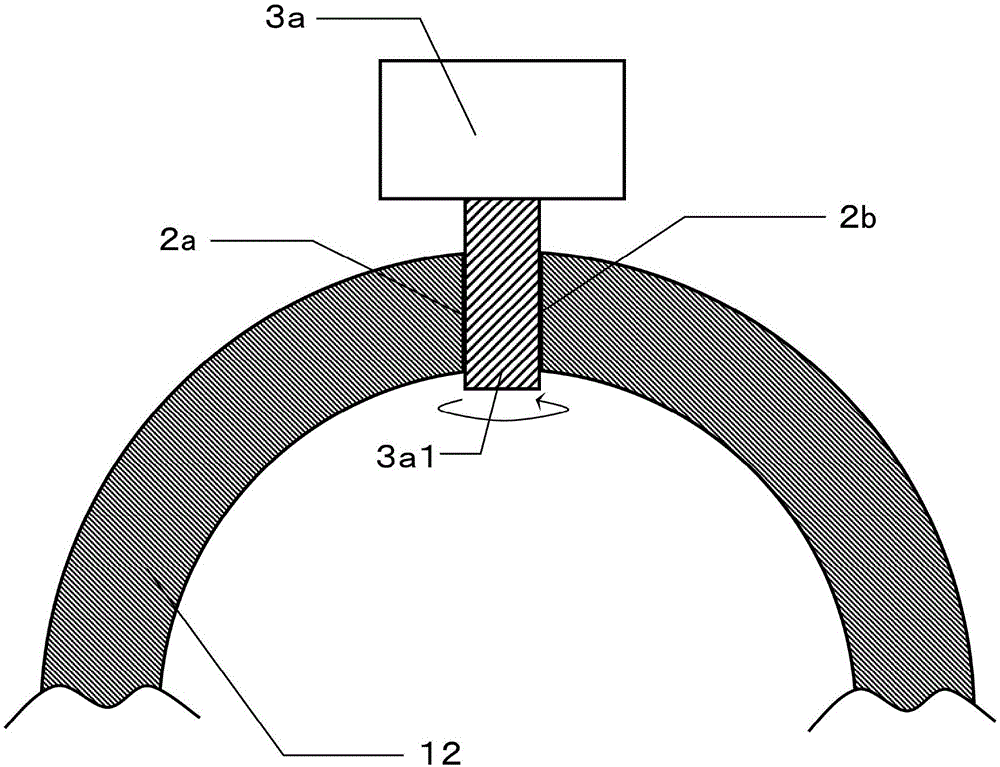

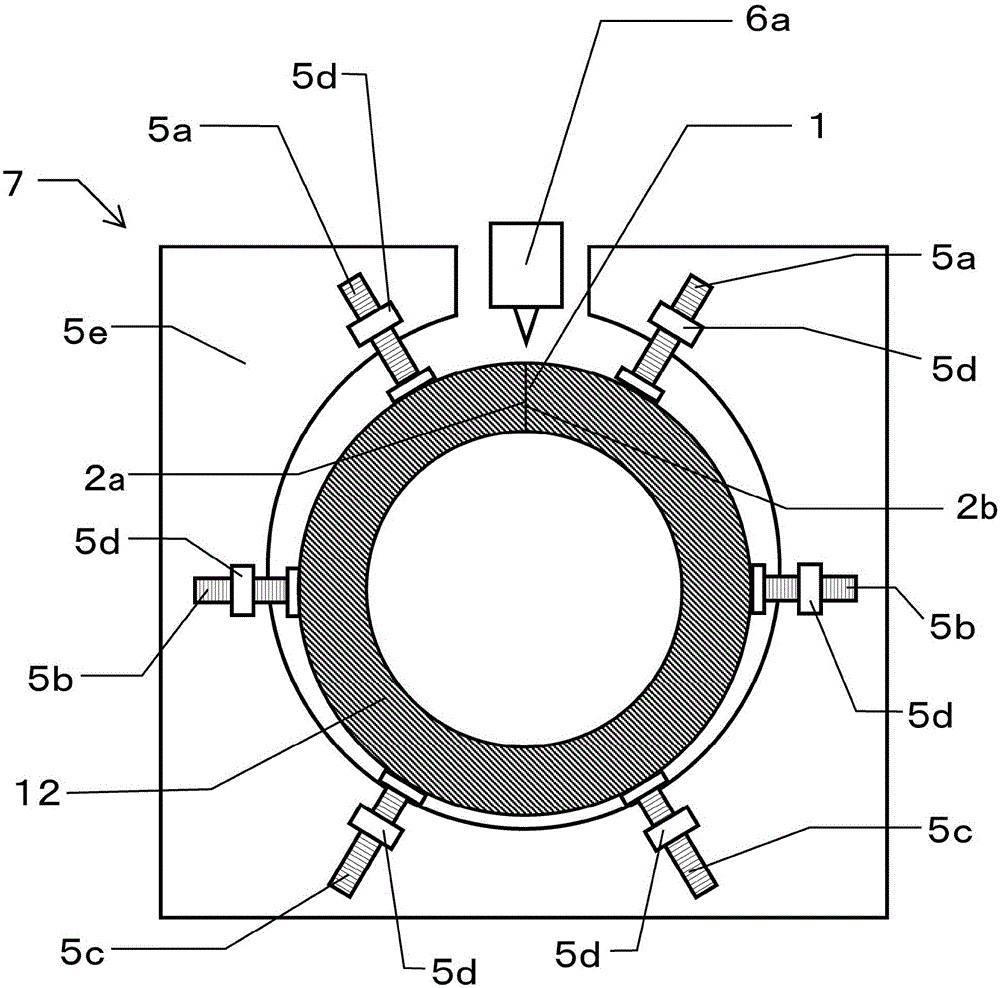

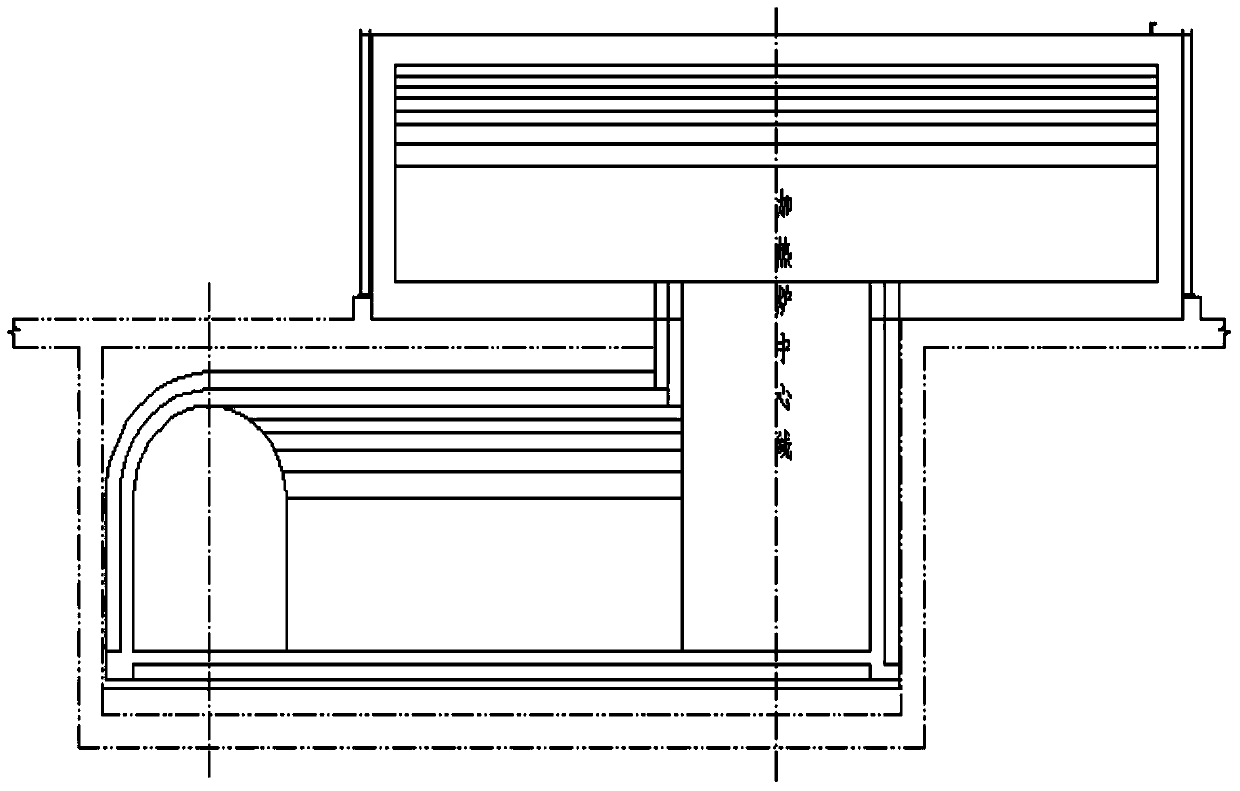

Production method for plate-bending hollow roll, plate-bending hollow roll, and device for steel plate production process

In the present invention, plate-bending processing in which a metal plate is bent into a cylindrical shape is performed. A butting left end surface (2a) and a butting right end surface (2b) of the metal plate (12) are subsequently tack welded by subjecting, to spot welding or the like, a side surface of a butt section (1). Thereafter, an end mill is used to subject the butt section (1) to joint processing, and an interval between the end surfaces is uniformly formed. The outer peripheral surface of the metal plate (12) which has been subjected to joint processing is then pressed by pressing bolts provided to a C-shaped fixation jig (7), to hold a gap in a reduced state. Thereafter, a laser beam welding device (6a) is used to perform laser beam welding on the butt section (1), and, as a result, the butt section (1) is joined, and the metal plate (12) bent into the cylindrical shape is formed into the cylindrical shape. Accordingly, a plate-bending hollow roll can be efficiently produced at low cost, while exhibiting a sufficient facility production capacity, said plate-bending hollow roll enabling the conveyance of steel plate with high surface quality, without having to imprint a roll-surface shape onto the steel plate to be conveyed.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

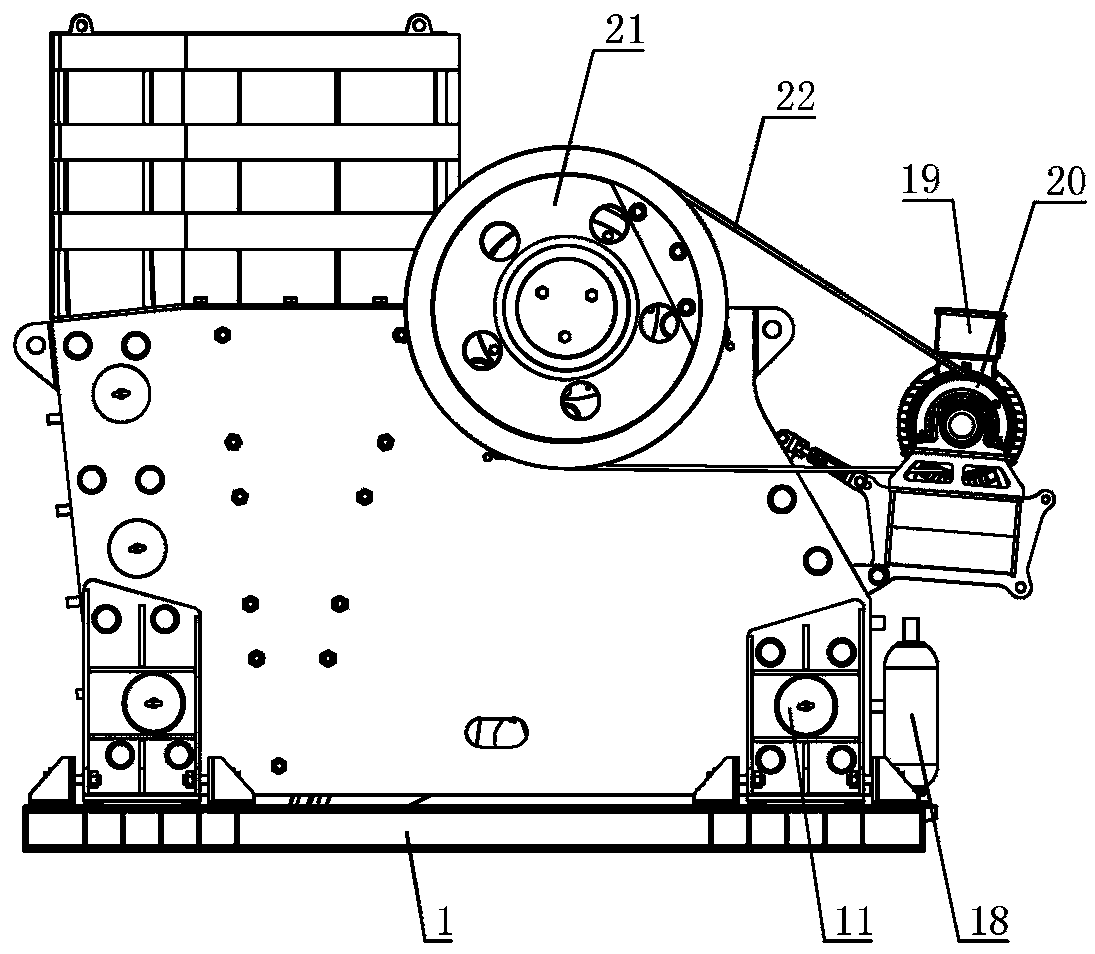

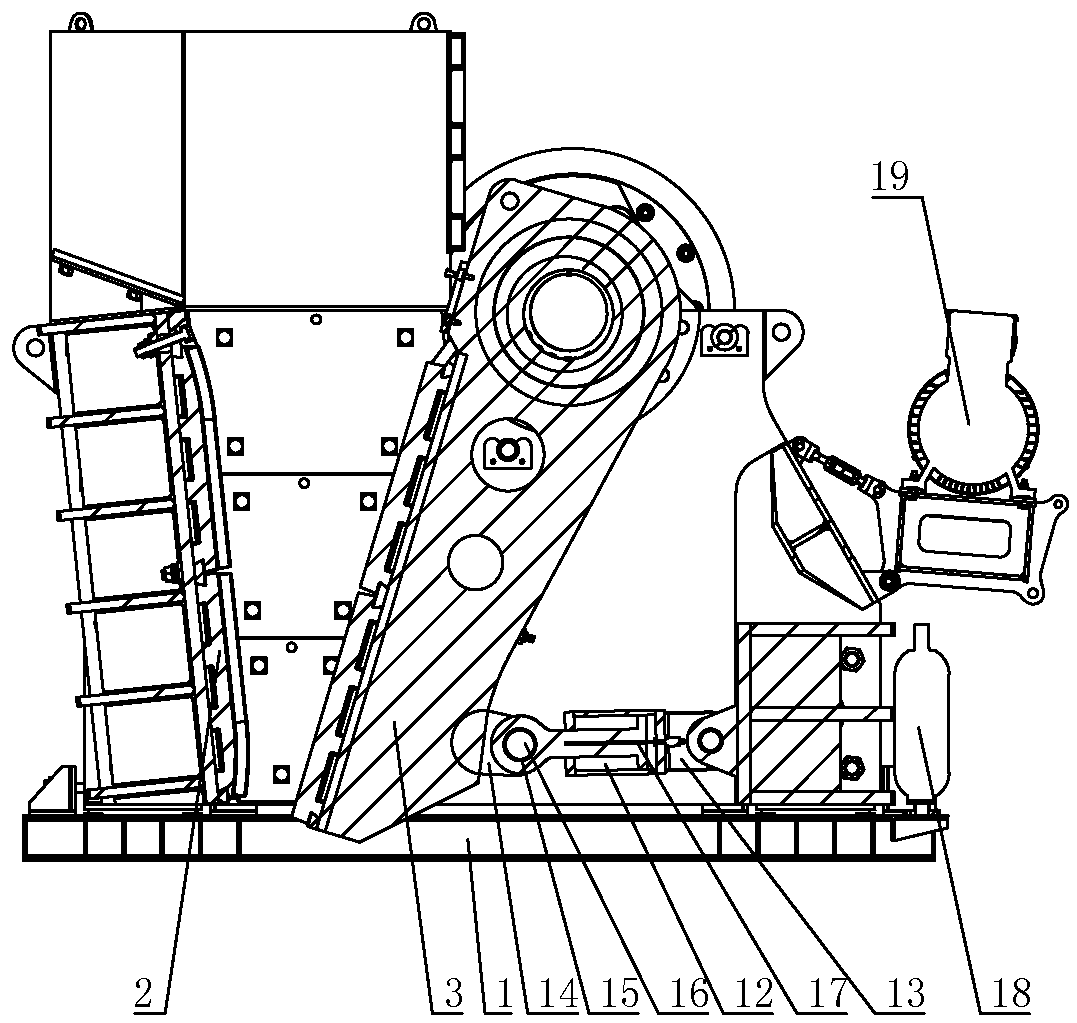

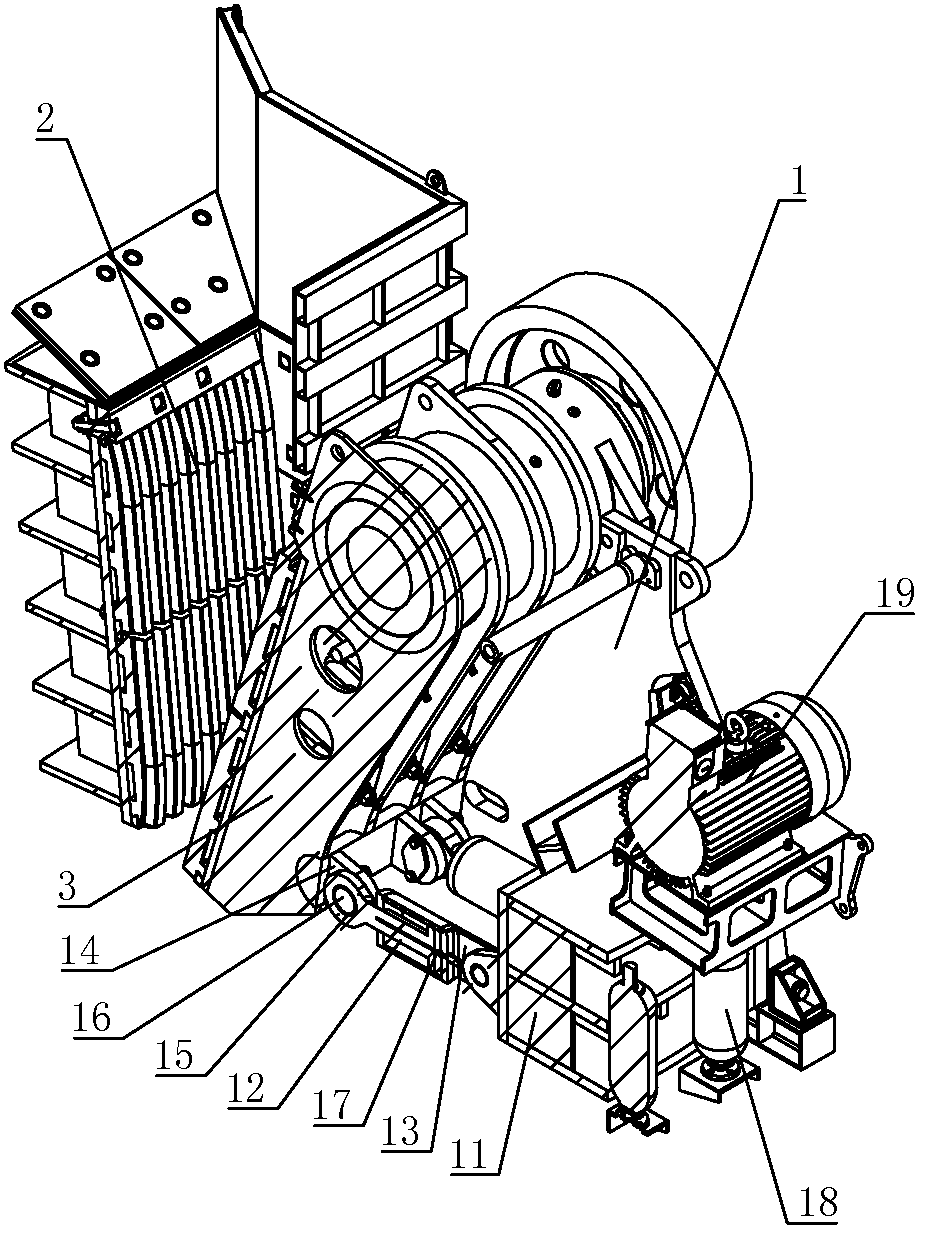

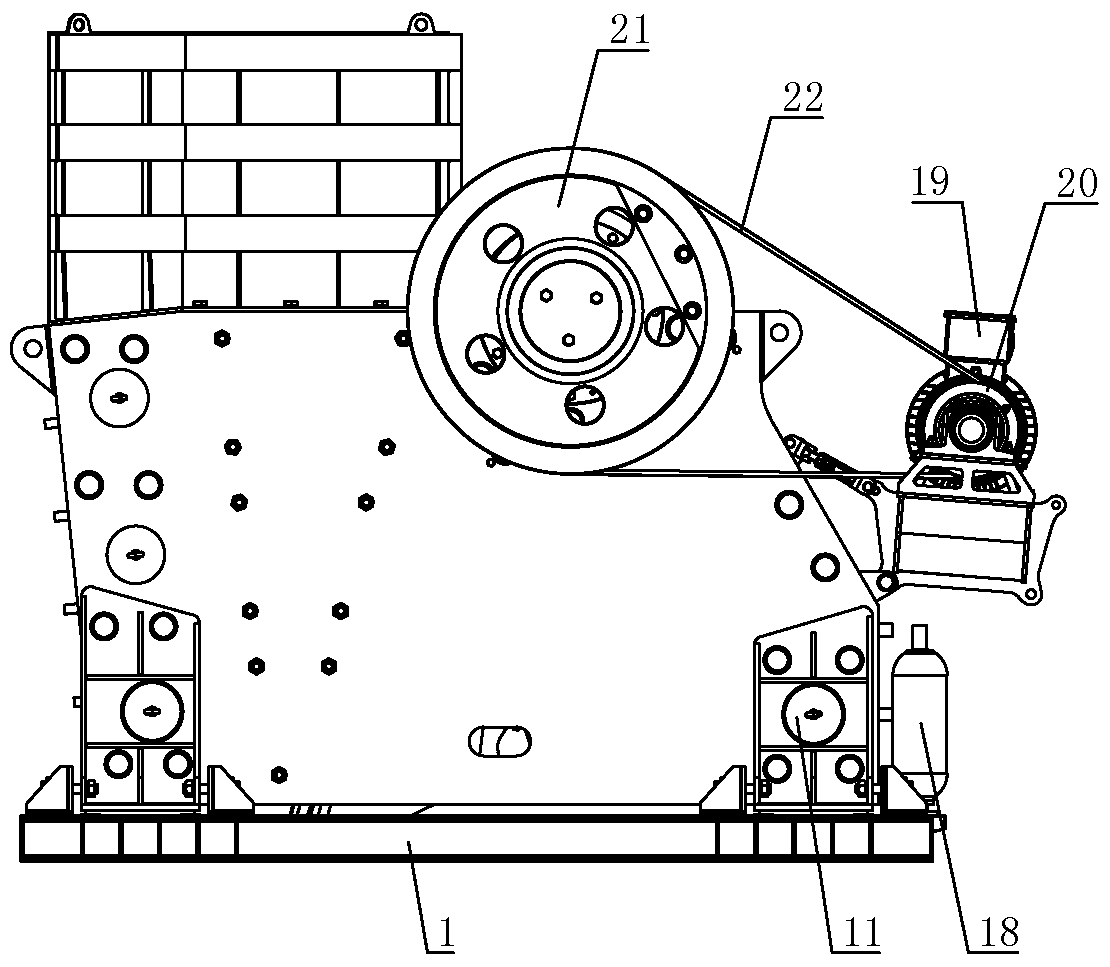

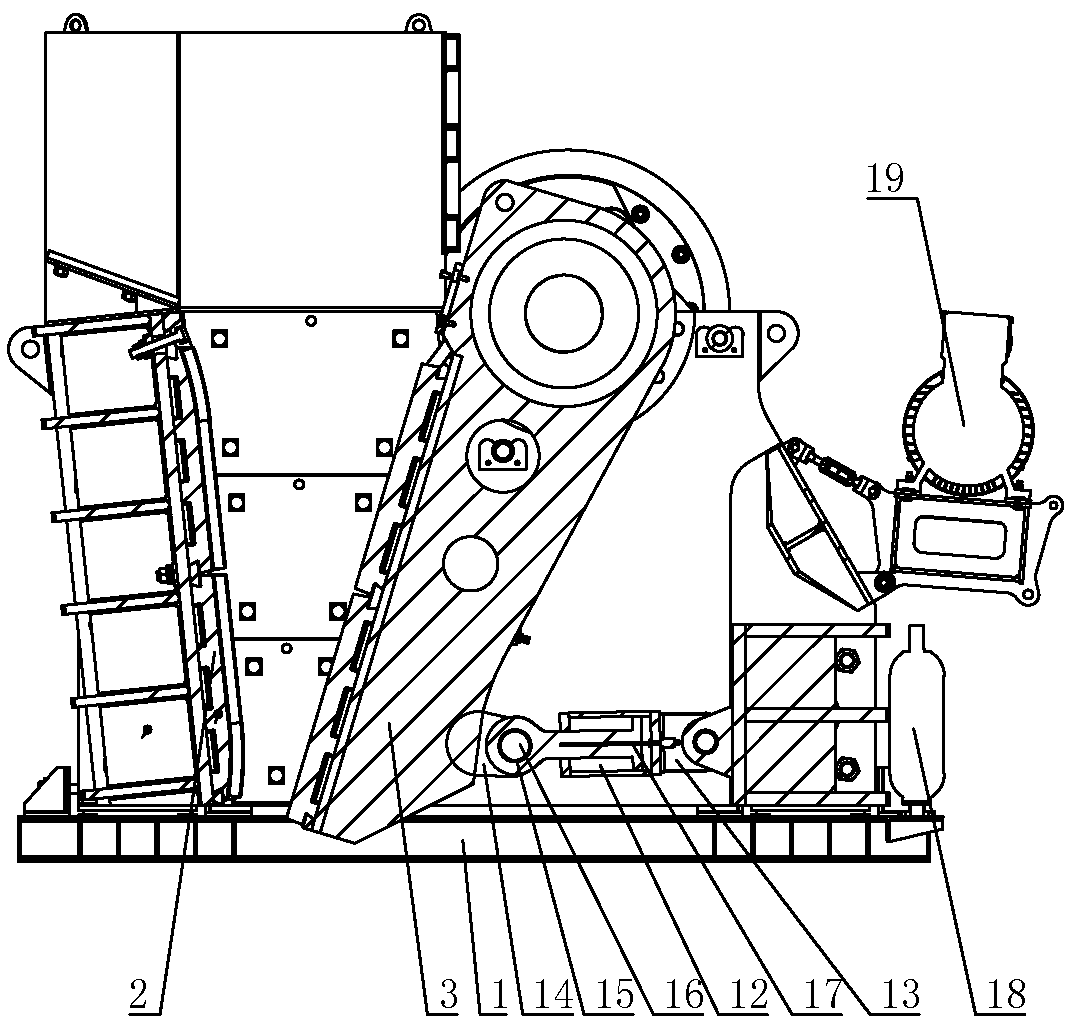

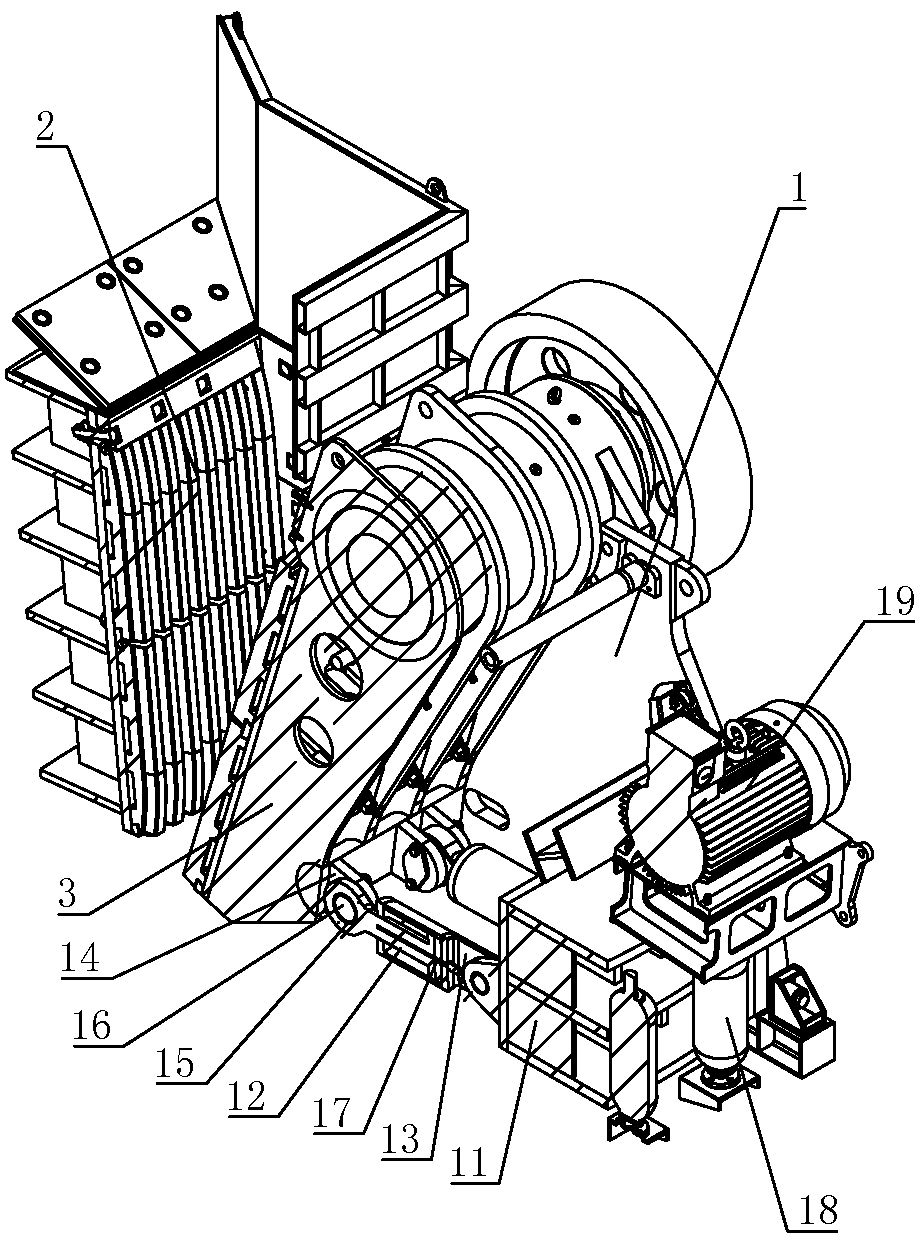

Efficient and intelligent jaw type crusher

ActiveCN110193396AExtended service lifeConfiguration changeableGrain treatmentsHydraulic cylinderEngineering

The invention provides an efficient and intelligent jaw type crusher. By means of the efficient and intelligent jaw type crusher, the problems that a working condition that an existing crusher cannotbe applied to various ore exists, an ore-discharging port cannot be adjusted automatically and accurately, and a crusher toggle plate is easy to go wrong are effectively solved. The efficient and intelligent jaw type crusher comprises a crusher rack, a fixed tooth plate and a movable jaw tooth plate and further comprises a movable jaw stroke adjustment device connected with the movable jaw tooth plate and an intelligent control device system. The movable jaw stroke adjustment device is used for adjusting the distance between the fixed tooth plate and the movable jaw tooth plate. The intelligent control device system comprises a movable jaw stroke compensation device and an ore-discharging port size automatic adjustment device. According to the efficient and intelligent jaw type crusher, configuration of the equipment can be made changeable through the movable jaw stroke adjustment device; the crusher can be applied to working conditions of various ore, and full play is given to the production capacity of the equipment; by adopting a pressure sensor and a displacement sensor on a hydraulic cylinder, the problem that manual repeated measurement is needed is solved; and by means of anoverloading automatic protective device, abrasion reminding of crusher tooth plates is achieved.

Owner:HENAN ZHONGYU DINGLI INTELLIGENT EQUIP CO LTD

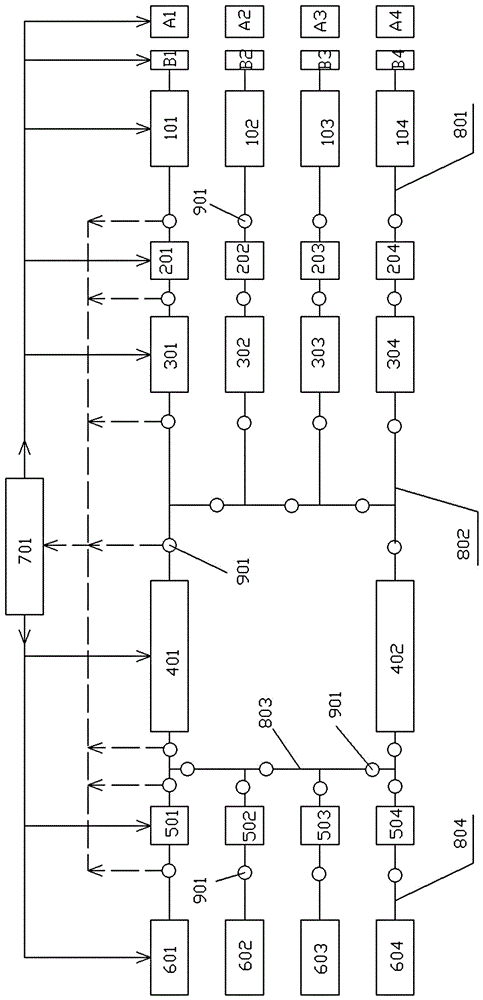

Photovoltaic glass deep processing tampering furnace parallel production control system

ActiveCN107179755AGuaranteed continuityLabor savingGlass tempering apparatusProgramme total factory controlControl systemProduction control system

The invention discloses a photovoltaic glass deep processing tampering furnace parallel production control system, which comprises four edge grinding lines, two tampering lines and four unloading lines, and is characterized in that each edge grinding line and each unloading line are provided with a conveying roller track, and a furnace-inlet transportation and distribution roller track is arranged between outlets of the four edge grinding lines and inlets of the two tampering lines; a furnace-outlet transportation and distribution roller track is arranged between outlets of the two tampering lines and inlets of the four unloading lines; the control system further comprises a DCS control center, each roller track is provided with a photoelectric switch used for detecting the glass position, each photoelectric switch is connected with an input interface of the DCS control center, and the DCS control center controls running of each device and regulates the start, stop and running speed of each device according to the position of a glass sheet; and the DCS control center controls the feeding speed of the furnace-inlet transportation and distribution roller track and the discharging speed of the furnace-outlet transportation and distribution roller track according to the load of a tampering furnace, and enables glass tampering to be dynamically balanced with glass feeding and discharging; and the photovoltaic glass deep processing tampering furnace parallel production control system performs unified linkage control and ensures the continuity of production.

Owner:CNBM YIXING NEW ENERGY CO LTD

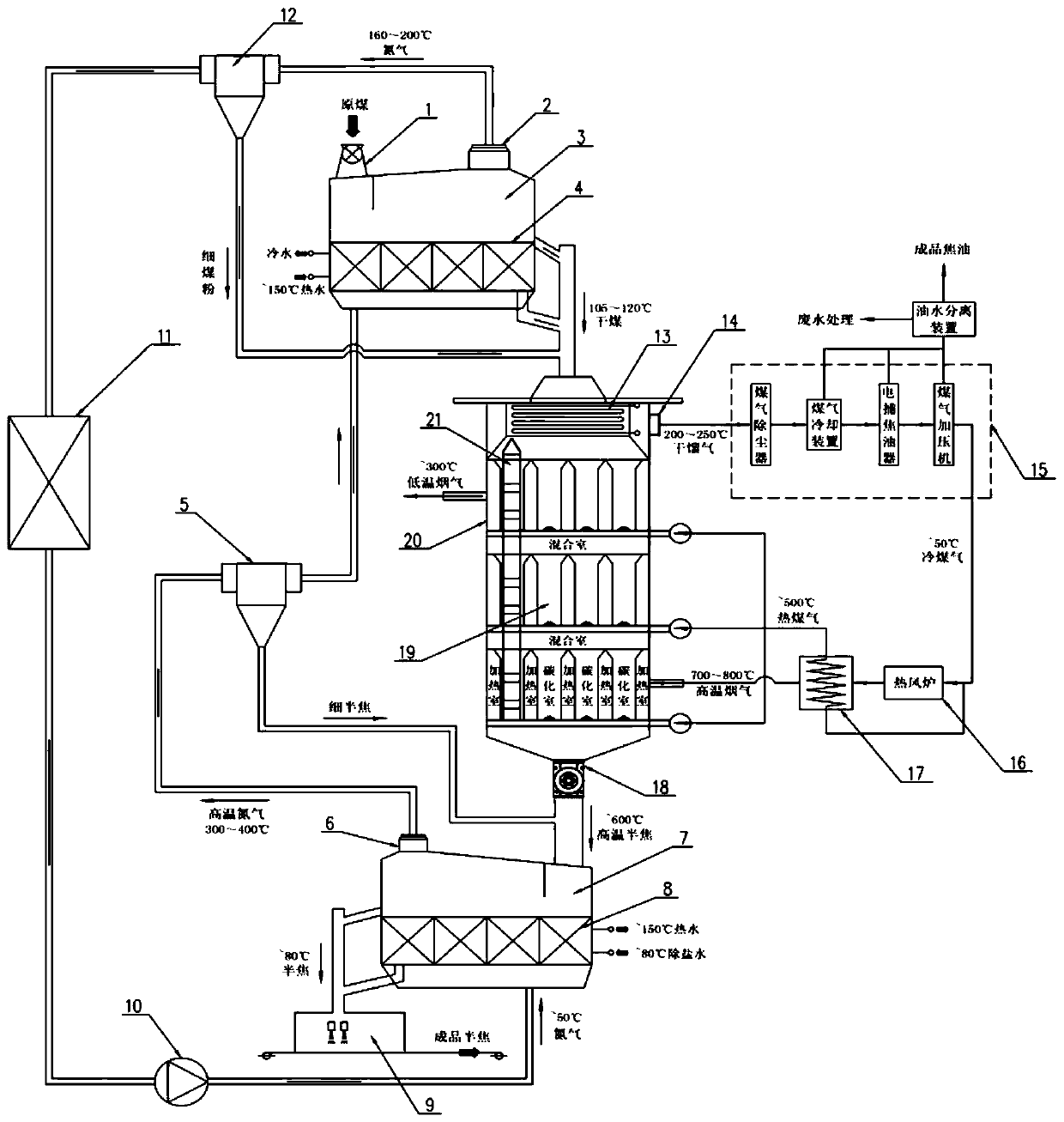

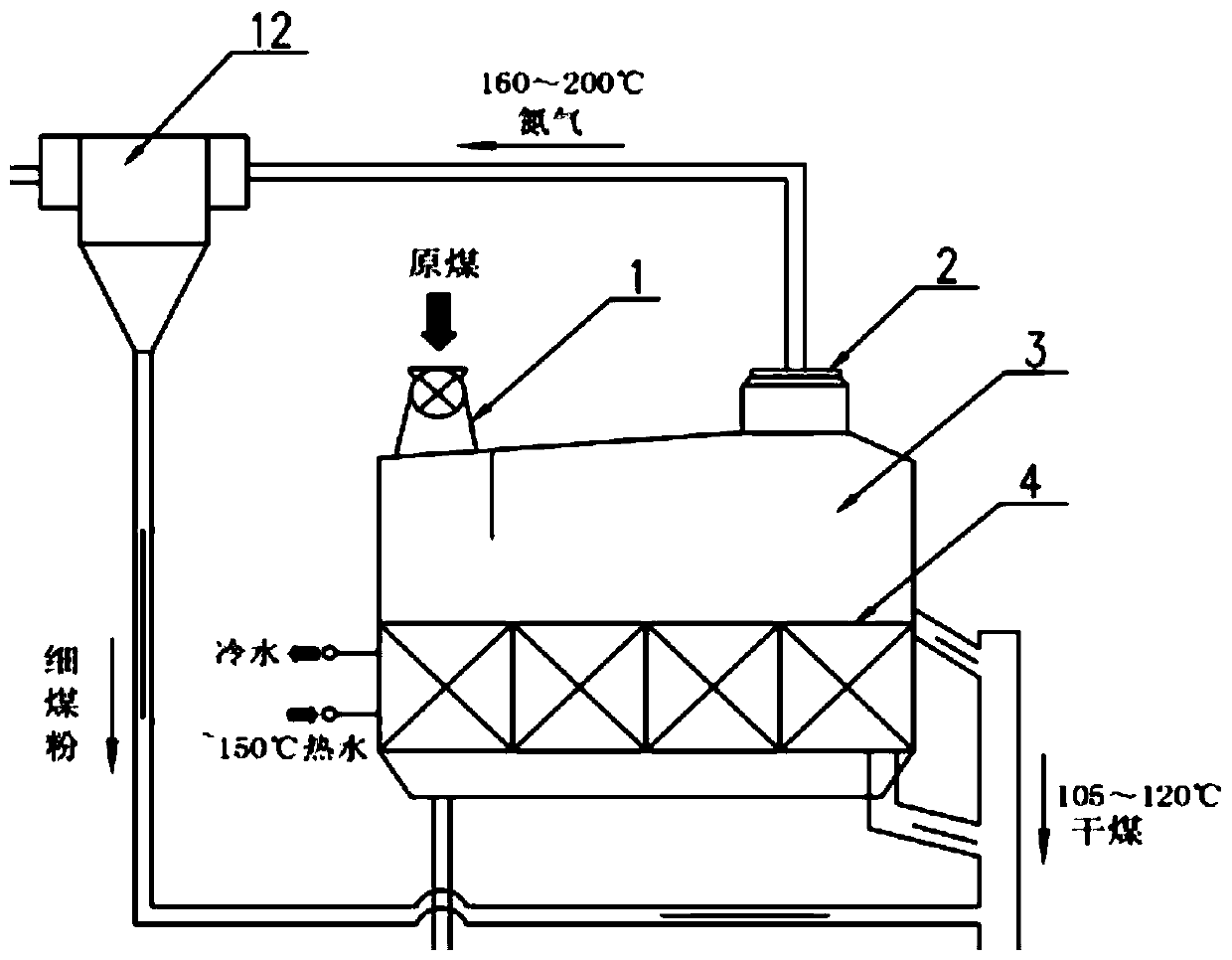

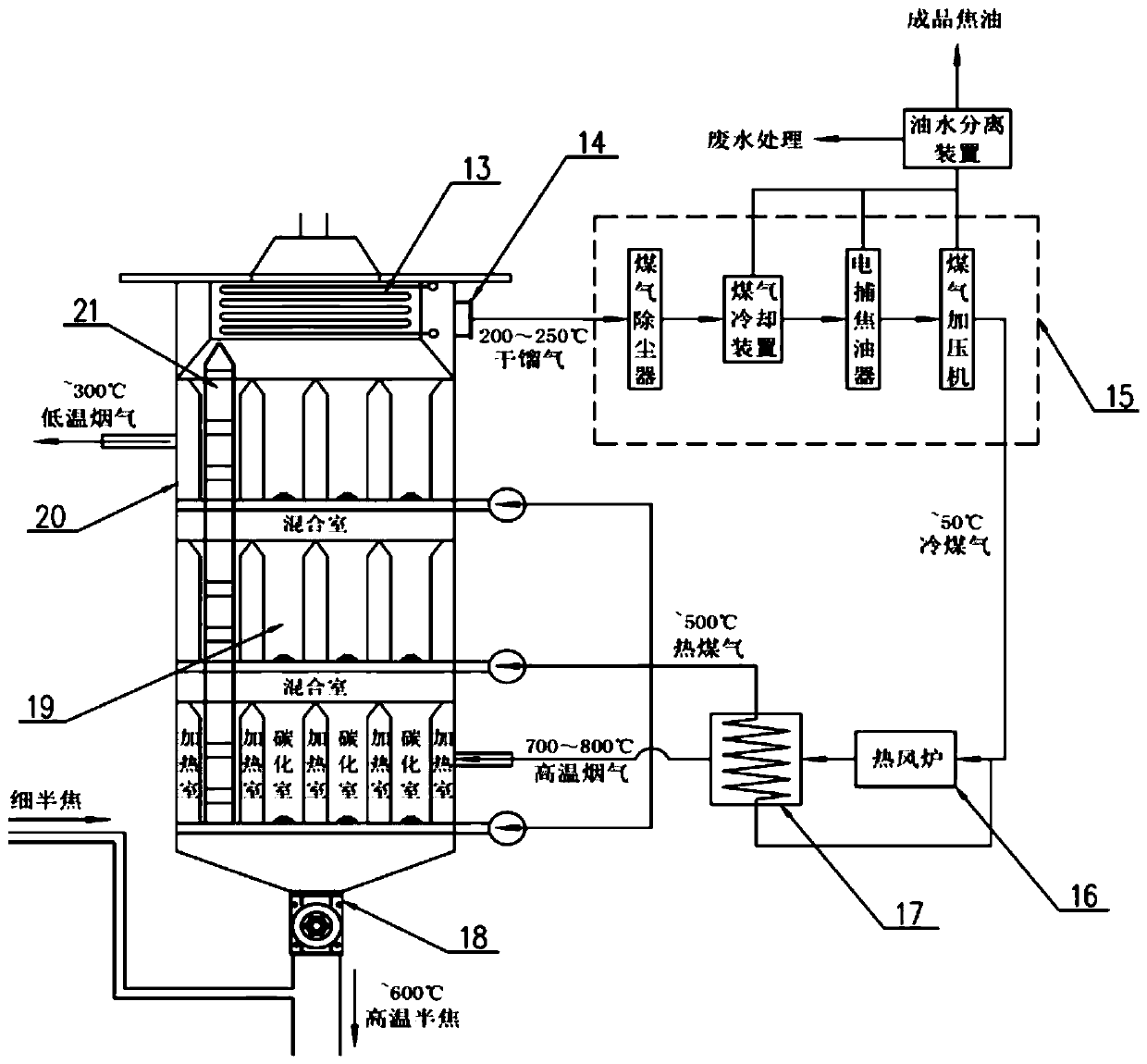

Dual-heat-source low-rank-coal low-temperature-carbonization pyrolysis technology system

PendingCN110117497AIncrease the speed of dry distillation pyrolysisGuaranteed calorific valueIndirect and direct heating destructive distillationEnergy inputCarbonizationNitrogen gas

The invention discloses a dual-heat-source low-rank-coal low-temperature-carbonization pyrolysis technology system. The dual-heat-source low-rank-coal low-temperature-carbonization pyrolysis technology system comprises a fluidized-bed raw-coal drying dehydration device, a low-rank-coal low-temperature-carbonization pyrolysis device, a fluidized-bed semi-coke cooling device, a nitrogen circulatingsystem and a dual-heat-source system; the dual-heat-source system comprises a pyrolysis-coal-gas heat supplying pipe system adopting one part of pyrolysis coal gas generated by the low-rank-coal low-temperature-carbonization pyrolysis device as a first heat source and one part of pyrolysis coal gas generated by the low-rank-coal low-temperature-carbonization pyrolysis device as a second heat source, the pyrolysis coal gas of the first heat source is burned into high-temperature flue gas through a fuel-gas hot air furnace in an external heating mode to become an external heat source of the low-rank-coal low-temperature-carbonization pyrolysis device, and purified pyrolysis coal gas of the second heat source is heated into hot coal gas through a coal gas reheater to directly enter a coal layer of the low-rank-coal low-temperature-carbonization pyrolysis device to participate a carbonization pyrolysis reaction. According to the dual-heat-source low-rank-coal low-temperature-carbonizationpyrolysis technology system, through recycling of waste heat of the technology system, energy consumption is reduced, the purity, a heat value and the coal-carbonization-pyrolysis finished-product recovery rate of output coal gas are increased, and the coking technology wastewater quantity is decreased.

Owner:WUXI YIEN TECH

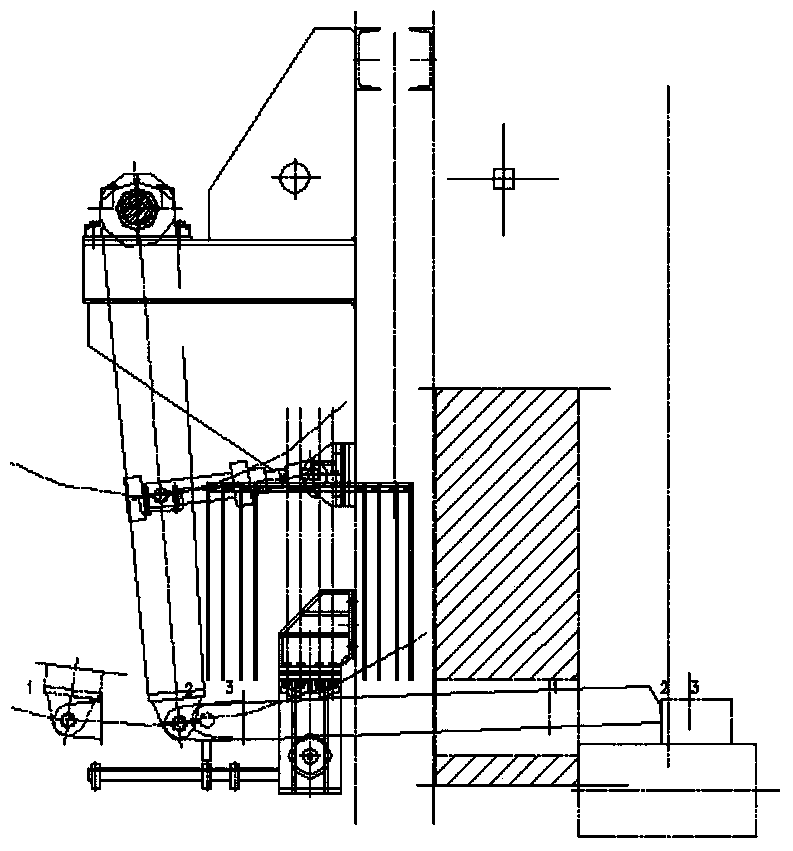

Rod and wire heating furnace achieving flexible matching direct hot loading of casting machine and rolling mill

ActiveCN103808150AIncrease hot delivery and hot charging rate and furnace entry temperatureIncrease productionCharge manipulationWaste heat treatmentFlueCharge type

The invention provides a rod and wire heating furnace achieving flexible matching direct hot loading of a casting machine and a rolling mill, and belongs to the technical field of industrial furnaces. The rod and wire heating furnace comprises a cantilever roller bed side-inlet and side-outlet step-type heating furnace body, accessory equipment, a loading end lower smoke exhausting tube, a smoke exhausting flue, a flexible matching loading machine and a suspension furnace-charging type pusher. The flexible matching loading machine is arranged at the end of the cantilever roller bed side-inlet and side-outlet step-type heating furnace body and the end of the accessory equipment, the suspension furnace-charging type pusher is arranged on the end of the cantilever roller bed side-inlet and side-outlet step-type heating furnace body, the end of the accessory equipment and the upper portion of the flexible matching loading machine, and the exhausting tube and the smoke exhausting flue are arranged at the end of the cantilever roller bed side-inlet and side-outlet step-type heating furnace body, the end of the accessory equipment and the lower portion of the flexible matching loading machine. The rod and wire heating furnace has the advantages that the problem that the steel making continuous casting machine and the steel rolling mill are not matched in production speed and production and maintaining system is solved, the hot conveying and hot loading furnace charging rate and hot conveying billet furnace charging temperature can be improved, and energy consumption of the heating furnace is reduced.

Owner:BEIJING SHOUGANG INT ENG TECH

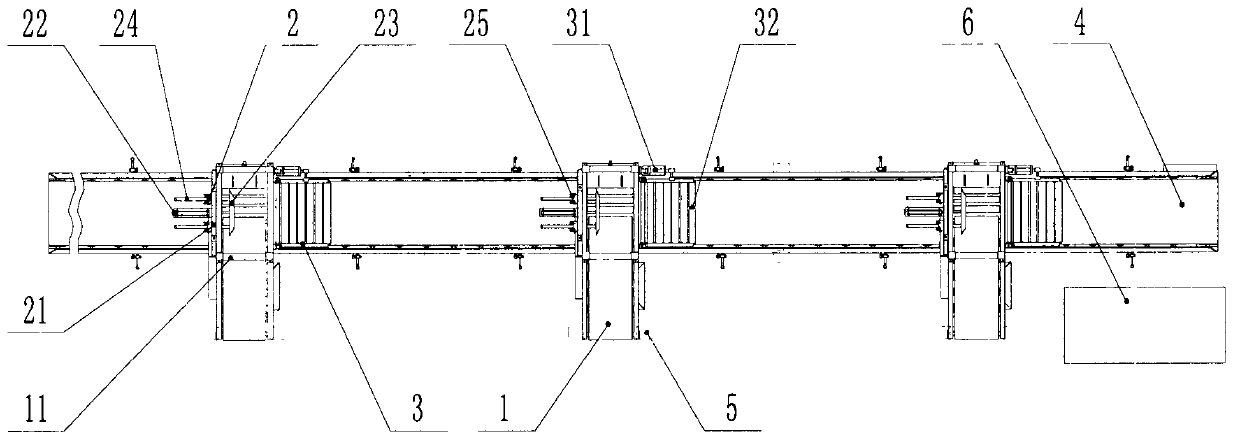

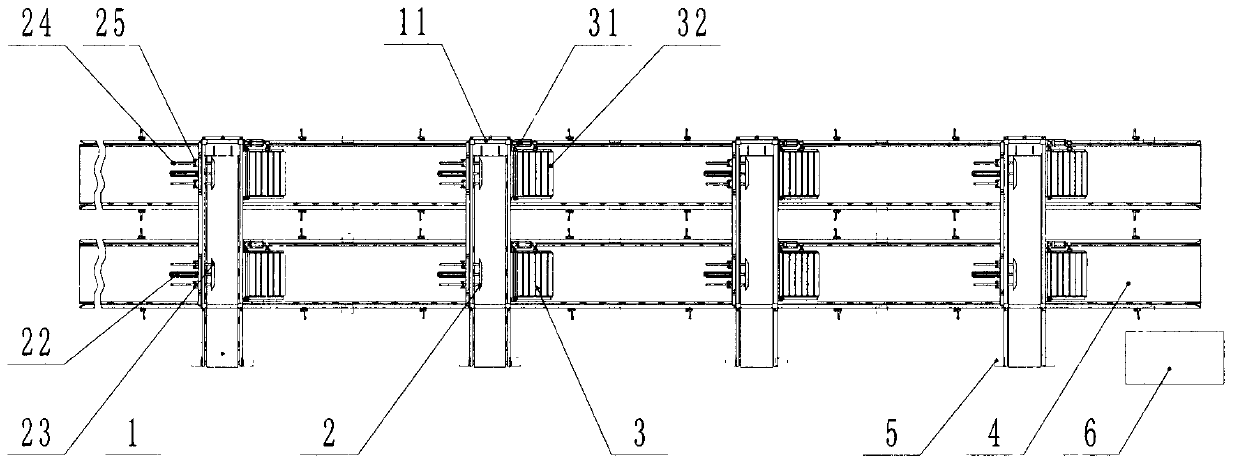

Automatic poured bag stacking and grouping machine

ActiveCN103129956AFully automatedMake full use of production capacityConveyor partsLand resourcesEngineering

The invention discloses an automatic poured bag stacking and grouping machine comprising entrance conveying units, bag-pouring devices, bag outlet devices, exit conveying units and sensors. The entrance conveying units and the exit conveying units are mounted in a mutually perpendicular manner; the entrance conveying units higher than the exit conveying units are linearly connected with the rear end of a packing conveyor; the number of the bag-pouring devices is the same as the number of the bag outlet devices; each pair of the bag-pouring device and the bag outlet device opposite to each other is disposed above the side of the entrance conveying unit; and the sensors are respectively disposed on frames of the entrance conveying units and the exit conveying units. The automatic poured bag stacking and grouping machine can be connected with a plurality of packing conveyors to sort and group bagged products disorderly delivered thereto from a plurality of the packing conveyors, and the sorted and grouped bagged products are collected to a conveyor or distributed to over two conveyors. Consequently, production capacity of a stacker is improved; unnecessary waste of equipment investment and management resources is avoided; occupied space is minimized; and valuable productive land resources are saved.

Owner:GUANGXI LIYUANBAO SCI & TECH

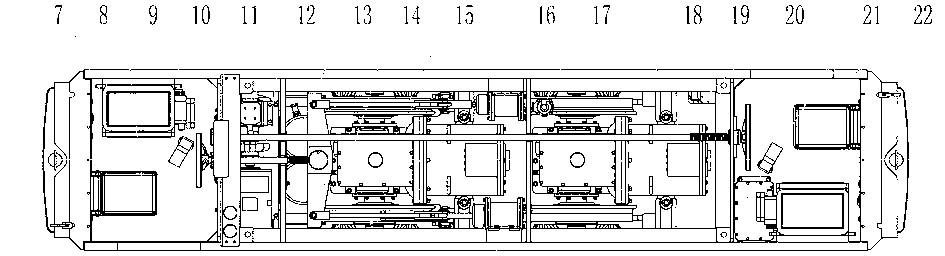

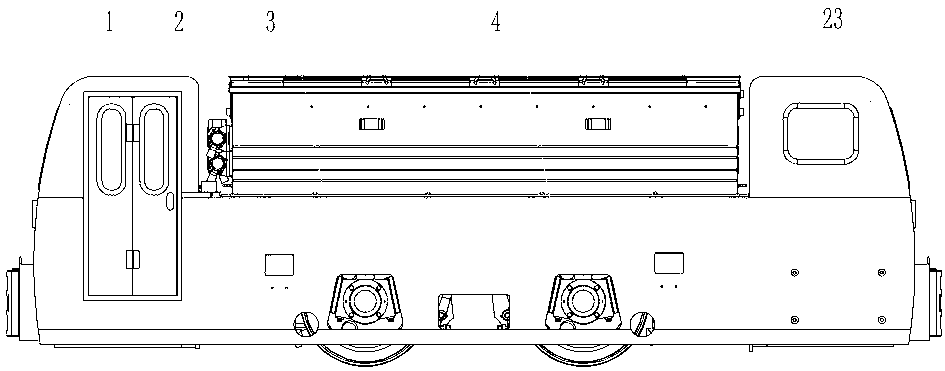

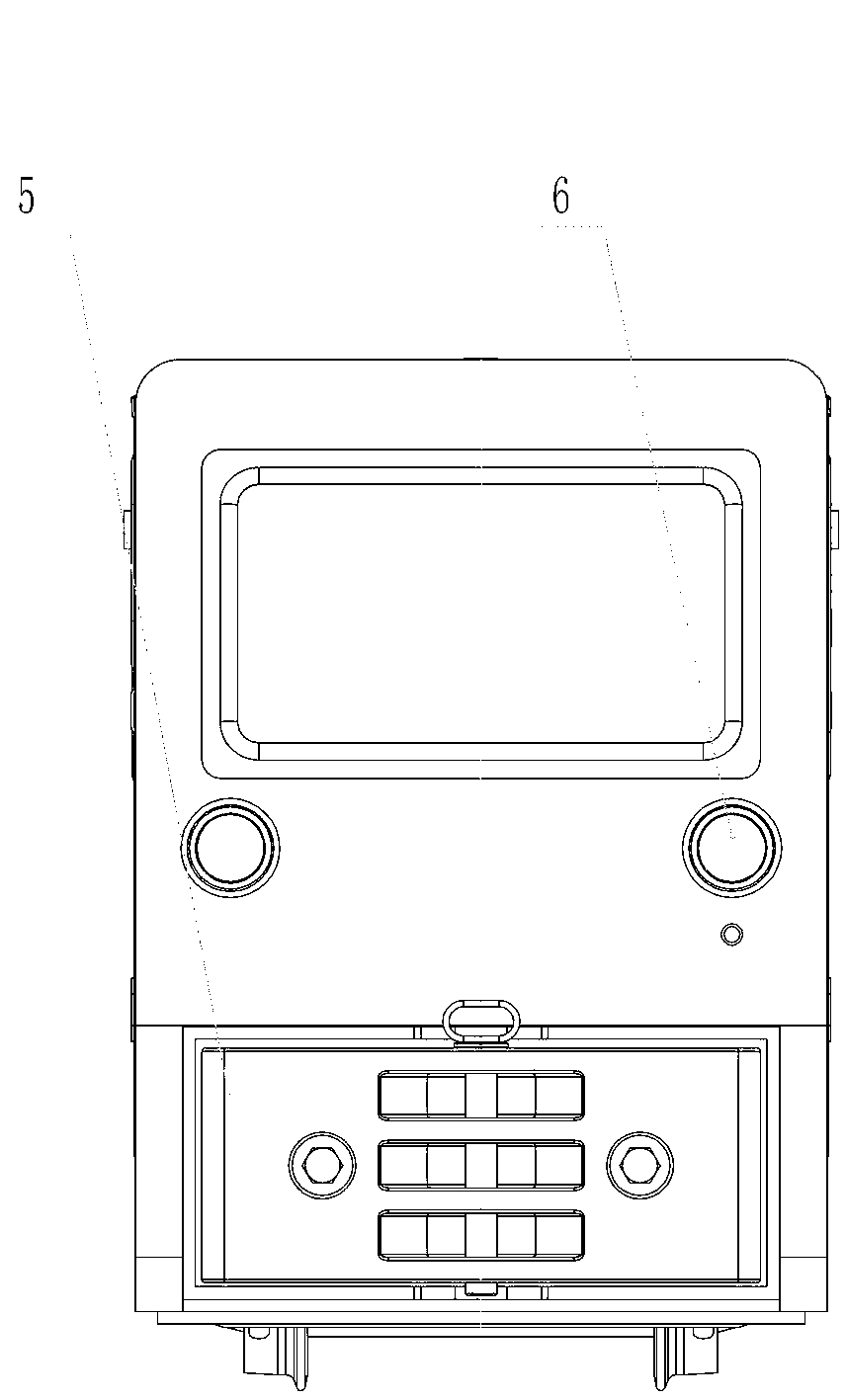

Storage-battery-type fast-frequency-conversion electric locomotive

ActiveCN103318189AMake full use of production capacityReduce energy consumptionElectric locomotivesMine carsVehicle frameLow speed

The invention relates to a storage-battery-type fast-frequency-conversion electric locomotive which belongs to a storage-battery-type fast-frequency-conversion electric locomotive. The electric locomotive is mainly used for solving technical problems such as large energy consumption, low speed, insufficient running capacity, low working efficiency, and the like of existing storage-battery-type fast-frequency-conversion electric locomotives. The invention adopts a technical scheme that: the electric locomotive comprises a cab (1), a storage battery box (2), and a frame (22). The frame (22) adopts a streamlined structure. The cab (1) and a vehicle rear control room (23) are respectively arranged on front and back ends of the frame (22). The storage battery box (2) is arranged on the upper part of the frame (22) between the cab (1) and the vehicle rear control room (23) An air braking device is arranged below the storage battery box (2) and on the back side of the cab (1). The electric locomotive is mainly used in coal mine tunnel transportation.

Owner:XIANGTAN ELECTRIC LOCOMOTIVE FACTORY

Shaking ladle premelting process for producing medium and low carbon ferromanganese

The invention relates to a shaking ladle premelting process for producing medium and low carbon ferromanganese. Medium manganese pre-shaking slag with alkalinity of 1.2-1.3 and MnO content of 20-25% and liquid silicomanganese are mixed according to the weight ratio of 1.0:1-1.2:1, and the mixture is loaded into a shaking ladle. The capacity of the ladle is 15 m<3>, a desilication reaction is carried out in the shaking ladle, the revolution of the shaking ladle is 40-60 RPM, and the shaking smelting time is 15-20 min. The invention has the advantages that one shaking ladle is big enough to match a 5000 kVA electric refining furnace to produce because the capacity of the shaking ladle is enlarged, the production capability of the 5000 kVA electric refining furnace is fully exerted, the heat loss is small, and the desilication rate is high. By reasonably controlling the revolution of the shaking ladle and the shaking smelting time, an optimal desilication effect can be achieved, the consumption of secondary refining ore is reduced, the smelting time is shortened, manganese element in slag can be recovered to the maximum extent, and the production cost of medium manganese alloy is reduced.

Owner:CITIC JINZHOU METAL

Intelligent control system for jaw crusher, and jaw crusher thereof

ActiveCN110193397AReduce maintenance costsFor intuitive readingGrain treatmentsIntelligent control systemEngineering

The invention relates to an intelligent control system for a jaw crusher, and the jaw crusher thereof, and effectively solves the problems that an existing crusher cannot be applied to working conditions of multiple ores, an ore discharge hole cannot be automatically and accurately adjusted, and a crusher toggle plate is easy to go wrong. The jaw crusher comprises a crusher rack, a fixed tooth plate and a movable jaw tooth plate, wherein the fixed tooth plate is fixedly arranged on the crusher rack; the movable jaw tooth plate is movably arranged on the crusher rack; a crushing chamber is formed between the fixed tooth plate and the movable jaw tooth plate; and the ore discharge hole is formed in the lower end of the crushing chamber. The jaw crusher further comprises a movable jaw strokeadjusting device and the four-in-one intelligent control system, so that the equipment can be flexibly configured to be applied to the working conditions of the multiple ores; by adopting a pressure and displacement sensor on a hydraulic cylinder, the problem that manual repeated measurement is required is solved; through an automatic overload protection device, the warning on the abrasion of thetooth plates of the crusher is realized, and the stable and fast protection feedback is realized; and automatic intelligent data feedback and acquisition are completely realized.

Owner:HENAN ZHONGYU DINGLI INTELLIGENT EQUIP CO LTD

Thixotropic chemical sealing channeling agent

ActiveCN102181274BMake full use of production capacityImprove efficiencyDrilling compositionSealing/packingSodium BentoniteCyclodextrin

The invention provides a thixotropic chemical sealing channeling agent. The sealing channeling agent comprises the following raw materials: 40 to 55 weight parts of iron rich low-carbon sulfur aluminate, 0.2 to 5.0 weight parts of sodium-based bentonite, 0.5 to 2.0 weight parts of fluid loss agent, 0.2 to 5.0 weight parts of white carbon black, 0.5 to 4.0 weight parts of cyclodextrin and / or starch and 30 to 50 weight parts of water. The chemical sealing channeling agent has the characteristics of strong adhesion and thermal stability, good durability, prominent cracking resistance and the like; the linear expansion rate reaches over 0.2 percent, the compressive strength reaches over 30MPa, and the shearing strength reaches over 10MPa; and by adding dispersant, fluid loss agent and thixotropic regulator, the sealing channeling agent has high thixotropic property and loss resistance.

Owner:PETROCHINA CO LTD

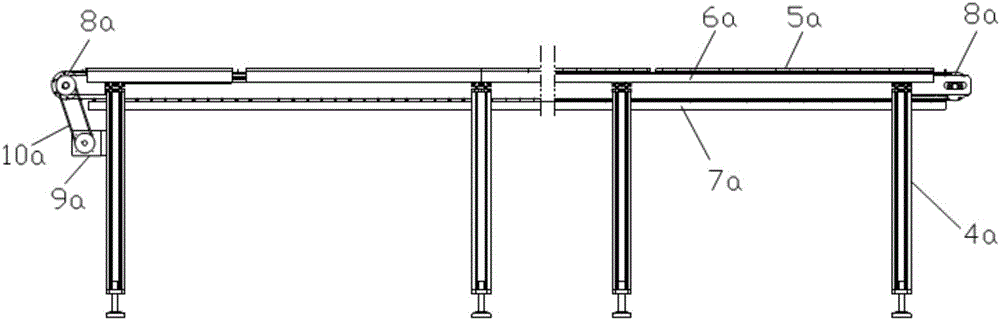

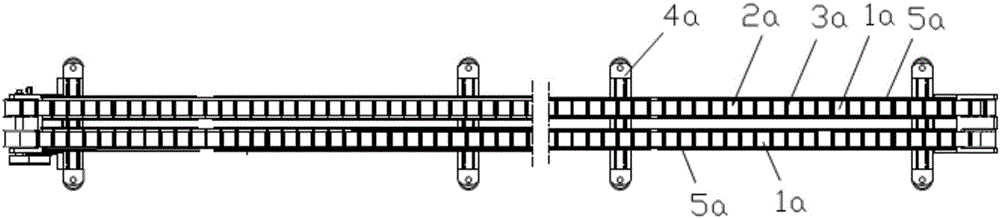

Automatic stacking, conveying and marshalling system

InactiveCN103274206AFully automatedMake full use of production capacityConveyor partsControl engineeringPalletizer

The invention discloses an automatic stacking, conveying and marshalling system which comprises a plurality of sets of inlet conveyor units which are distributed in parallel, a set of outlet conveyor units, a plurality of guiding devices, a plurality of sensors and an electronic control cabinet, wherein the outlet conveyor units are vertically installed at the output ends of the inlet conveyor units, the guiding devices are installed at the connecting corners of the inlet conveyor units and the outlet conveyor units and used for guiding steering, the sensors are installed on the inlet conveyor units and the outlet conveyor units respectively, and the electronic control cabinet is electrically connected with the inlet conveyor units, the outlet conveyor units and the sensors. The automatic stacking, conveying and marshalling system is simple in structure, reliable in operation, and capable of ensuring normal stacking operation of an automatic stacker crane and meeting requirements for efficient operation of the stacker crane.

Owner:GUANGXI LIYUANBAO SCI & TECH

Mixed sintering ore

ActiveCN104988258AIncrease usage ratioImprove blast furnace conditionBlast furnace detailsAlkalinityBlast furnace

The invention discloses mixed sintering ore. The mixed sintering ore is prepared by mixing the following materials: acid sintering ore with the alkalinity being 0.6 to 0.8 and alkaline sintering ore with the alkalinity being 1.8 to 2.3 according to the weight ratio of being 1:3 to 5. The mixed sintering ore is prepared by mixing the following materials: acid sintering ore with the alkalinity being 0.6 to 0.8 and alkaline sintering ore with the alkalinity being 1.8 to 2.3 according to the weight ratio of being 1:3 to 5, wherein the acid sintering ore accounts for 1 part, and the alkaline sintering ore accounts for 3 to 5 parts, due to the mixed matching, the condition that the acid sintering ore with the alkalinity being 0.6 to 0.8 can not be independently used for blast-furnace production is overcome; the average alkalinity of the mixed sintering ore is about 1.62 by measurement, and the use ratio of the sintering ore in a blast furnace can reach 88 percent to 90 percent of the use amount of iron-making materials in the blast furnace, so that the productivity of a sintering machine can be fully exerted; after the use ratio of the sintering ore is greatly increased, more benefit is brought for smooth conduction of the furnace condition, reduction of fuel consumption, improvement of technical indexes of the blast furnace and reduction of molten iron.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

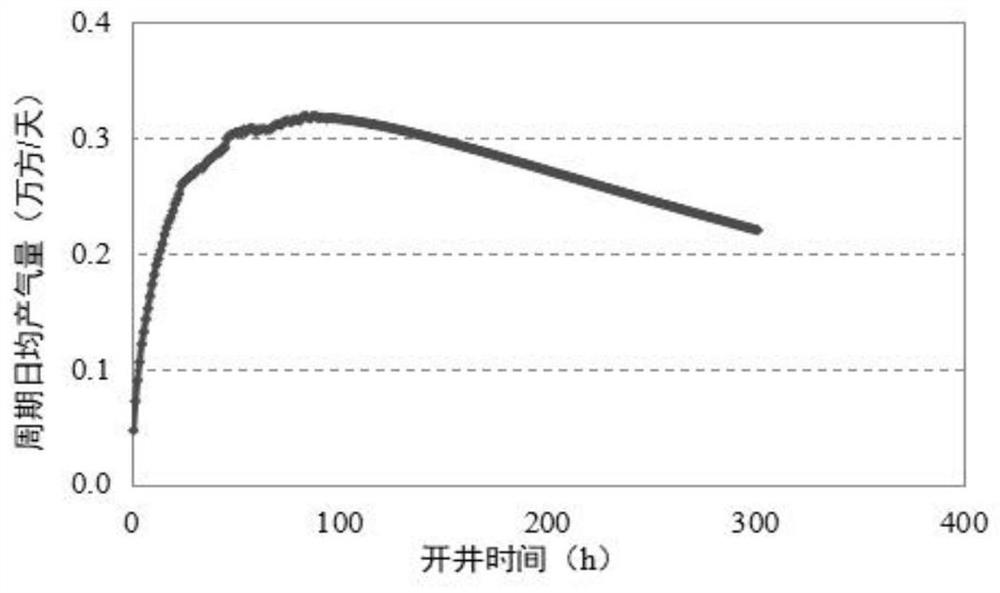

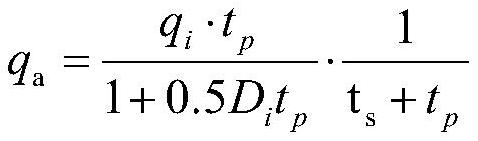

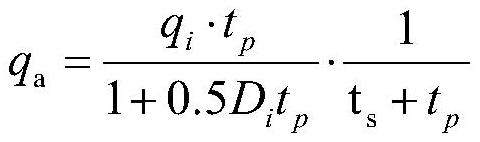

Method for optimization of well opening time of tight gas reservoir intermittent well

PendingCN112228053AThe result is accurateReliable resultsDesign optimisation/simulationSpecial data processing applicationsEvaluation resultThermodynamics

The invention provides a method for optimization of the well opening time of a tight gas reservoir intermittent well. The method is characterized in that on the basis of the feasibility analysis of optimization of the well opening time of the intermittent well, a relation curve of the daily average gas production rate of the intermittent period and the well opening time is established by utilizingreal-time production data, and the optimal well opening time of the intermittent gas well is determined by tracking and analyzing the occurrence time of the maximum value of the daily average gas production rate of the intermittent period. Compared with a conventional method, the method considers the actual yield change characteristics of the gas well and has the advantage that the evaluation result is more accurate and reliable.

Owner:PETROCHINA CO LTD

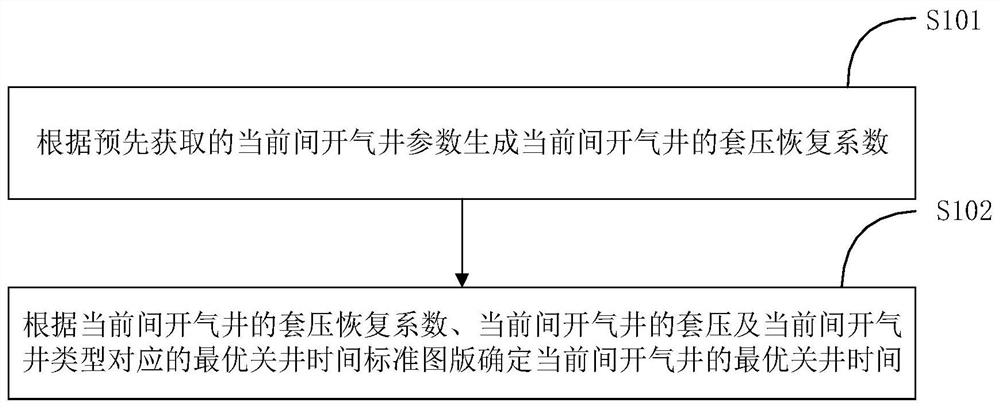

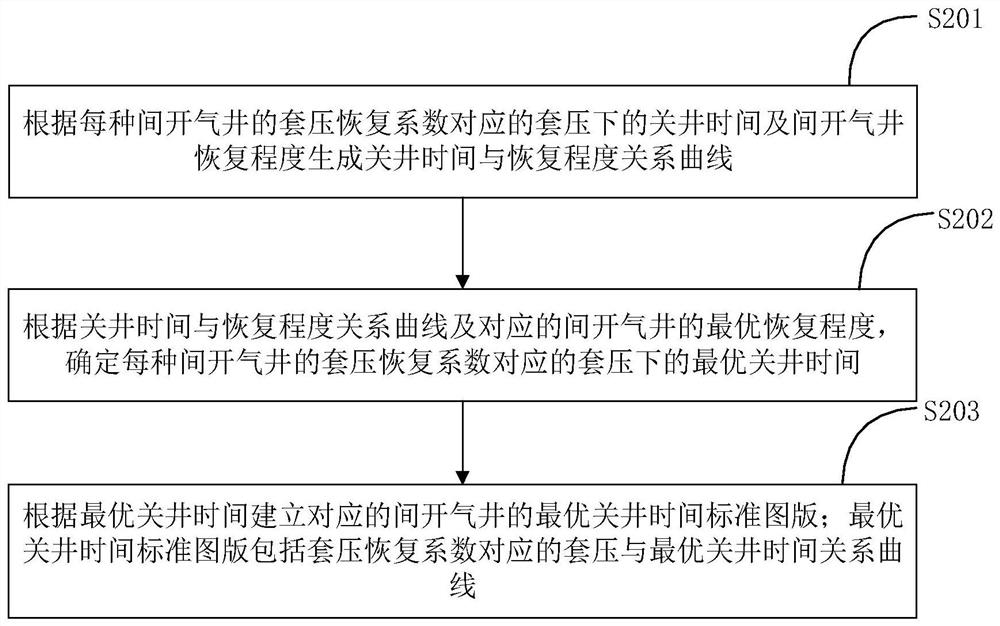

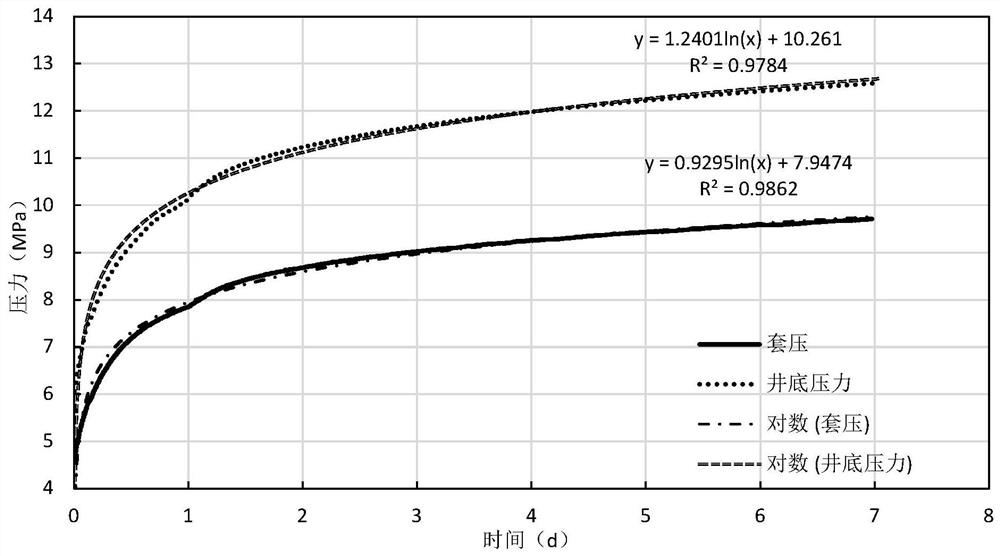

Intermittent opening gas well shut-in time determination method and system

ActiveCN113051698AMake full use of production capacityIncrease the rate of opening timeForecastingFluid removalThermodynamicsProcess engineering

The invention provides an intermittent opening gas well shut-in time determining method. The intermittent opening gas well shut-in time determining method comprises: generating a casing pressure recovery coefficient of a current intermittent gas well according to current intermittent gas well parameters obtained in advance; and determining the optimal well shut-in time of the current intermittent gas well according to the casing pressure recovery coefficient of the current intermittent gas well, the casing pressure of the current intermittent gas well and the optimal well shut-in time standard chart corresponding to the type of the current intermittent gas well. The productivity of the intermittent gas well can be further fully exerted, and the well opening time rate and yield of the intermittent gas well are improved.

Owner:PETROCHINA CO LTD

A smart card production system and method

ActiveCN105913115BHigh degree of automationHigh card feeding efficiencyConveying record carriersRecord carriers used with machinesSmart cardEngineering

The invention discloses an intelligent card production system and method. The production system comprises a card conveying total line and a plurality of intelligent card machining devices. The intelligent card machining devices are divided into upstream intelligent card machining devices for conveying cards to the card conveying total line and downstream intelligent card machining devices for obtaining the cards from the card conveying total line. A card carrying device for carrying the cards is arranged between each set of intelligent card machining device and the card conveying total line. The card conveying total line comprises a conveying belt of a closed circulation structure and a power mechanism for driving the circulation operation of the conveying belt. Card seats for accommodating cards are uniformly arranged on the conveying belt along the length direction of the conveying belt. According to the invention, the plurality of intelligent card machining devices and the card conveying total line serving as a link are combined to form the production system, the automatic degree is high, the number of the combined machining devices is not limited, the production efficiency is high, and the whole conveying process of the cards can be tracked.

Owner:GUANGZHOU MINGSEN TECH CO LTD

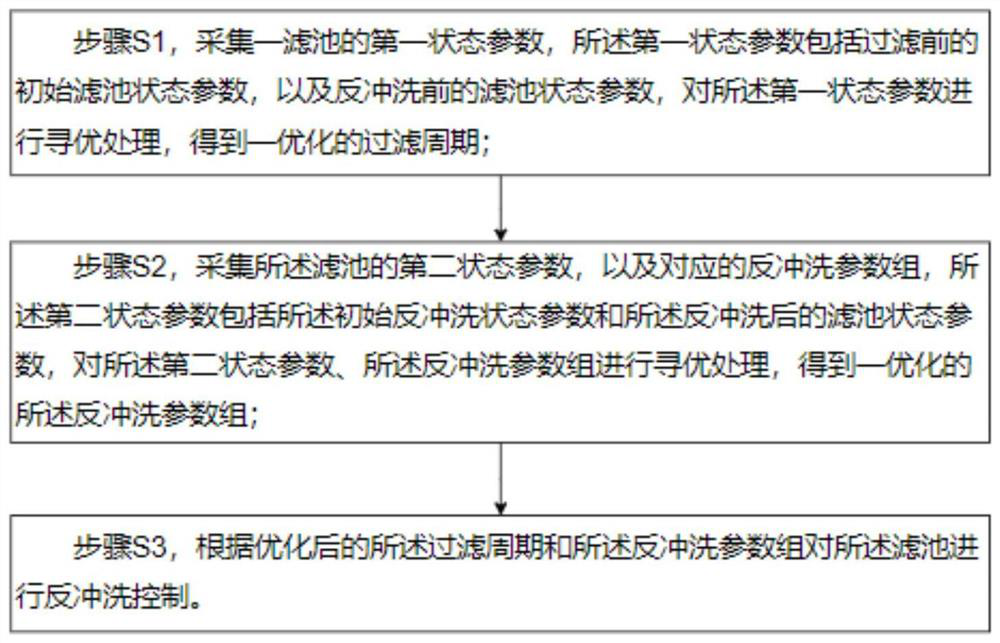

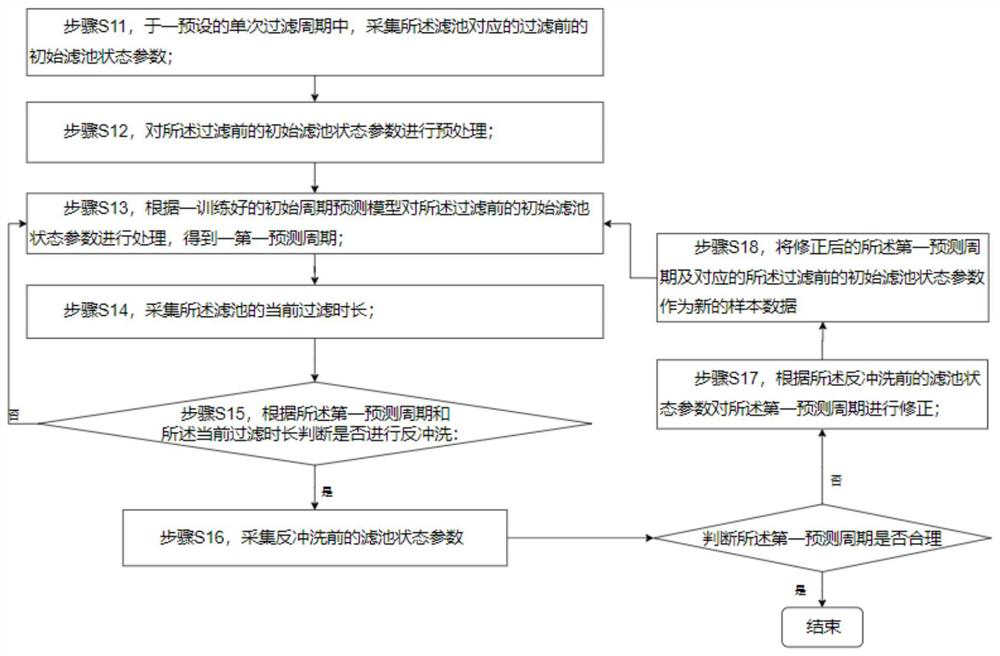

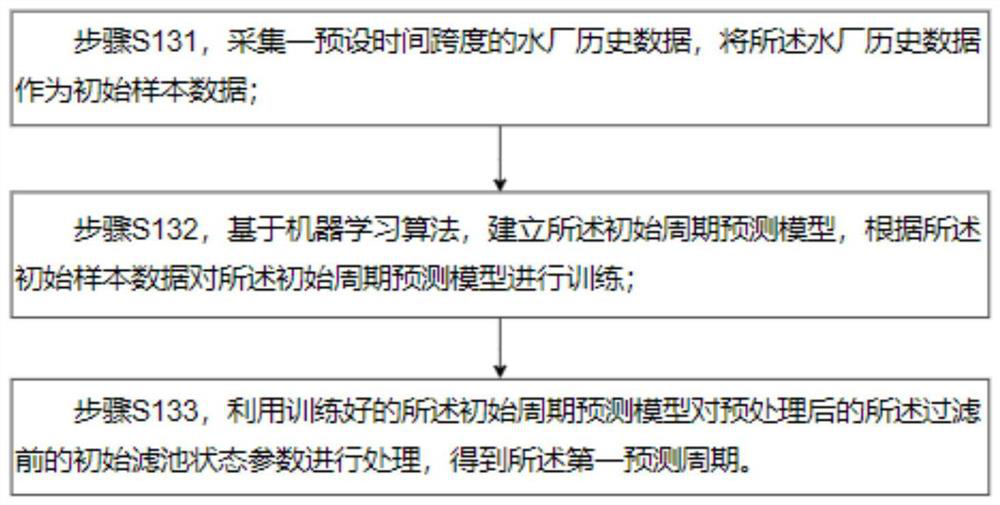

Filter backwashing control method

ActiveCN112915641AMake full use of production capacityRealize fine controlLoose filtering material filtersGravity filtersProcess engineeringWater cut

The invention discloses a filter backwashing control method, and belongs to the field of filter backwashing. The method comprises the following steps: S1, collecting a first state parameter of a filter tank, and optimizing the first state parameter to obtain an optimized filter period; S2, acquiring a second state parameter of the filter tank and a corresponding backwashing parameter group, and optimizing the second state parameter and the backwashing parameter group to obtain an optimized backwashing parameter group; and S3, carrying out backwashing control on the filter tank according to the optimized filter period and backwashing parameter group. The method has the beneficial effects that: the filtering period and backwashing parameters of the filter tank are optimized, so that the backwashing process of the filter tank is optimized and controlled, the water yield is further improved, the energy consumption and the production cost are reduced, and the refined control of the filtering link is realized.

Owner:SHANGHAI WPG WISDOM WATER CO LTD

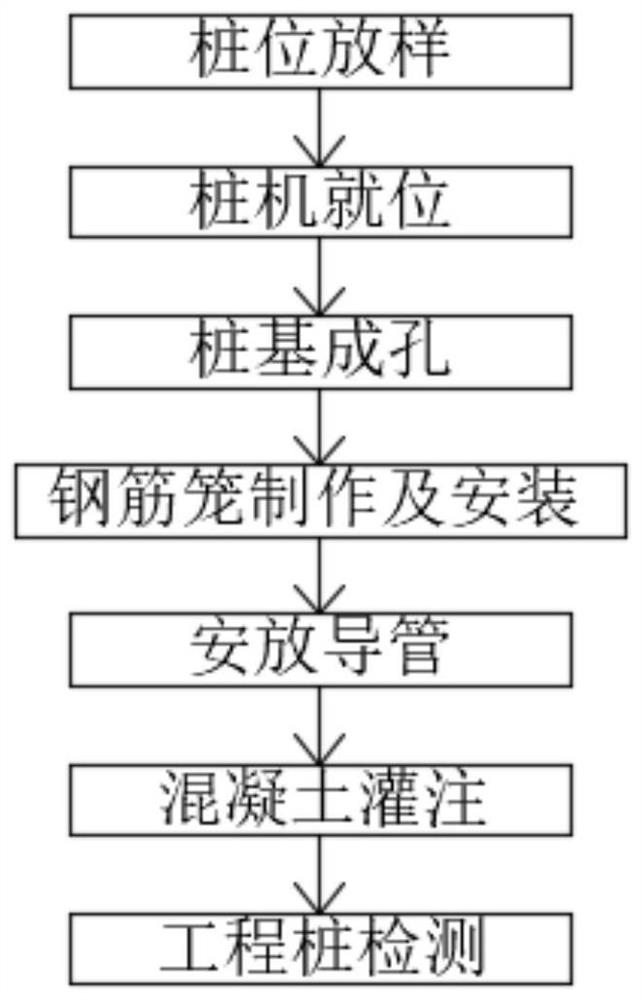

Construction process of cast-in-situ bored pile

InactiveCN112281821AAvoid confusionAvoid errorsFoundation testingBulkheads/pilesProduction lineVertical deflection

The invention discloses a construction process of a cast-in-situ bored pile. The construction process comprises the steps of lofting the position of the pile, positioning a pile machine, forming a pile foundation hole, manufacturing and mounting a reinforcement cage, placing a guide pipe, pouring concrete and detecting an engineering pile. The construction process has the beneficial effects that apile position control pile adopts a wood pile and a small nail, the buried depth is not less than 20 cm, and the pile position is preferably protected; additionally, stake numbers are marked, so thatconfusion is prevented; control points of a construction site are checked frequently, so that errors are avoided; a steel plate with the thickness of 20 mm is cushioned under the pile machine, so that uneven subsidence is avoided, and excessive vertical deflection of the formed hole, unqualified perpendicularity and even toppling accidents of a drilling machine are avoided; and according to the construction process, mechanical equipment which adapts to engineering and has good performance is adopted and is scientifically arranged on a production line, so that the production capacity of the equipment is brought into full play, and the environment-friendly and civilized construction is facilitated.

Owner:中铁十六局集团电气化工程有限公司 +1

Light thermal-insulation ceramic tiles and preparation method thereof

The invention discloses light thermal-insulation ceramic tiles, which are prepared by using the following raw materials in percentage by weight: 60.0 to 90.0 percent of ceramic tile raw material, 2.0 to 10.0 percent of additive, 10 to 20 percent of pore-forming material and 0.01 to 2 percent of foaming agent. The ceramic tiles are light, nonabsorbent, heat-proof, fire retardant, nontoxic, harmless, chemical corrosion resistance and mouldproof. The ceramic tiles have a small conductivity factor, stable performance and high mechanical strength. The ceramic tiles are low in cost, simple in process, convenient and quick in construction and good in decoration effect.

Owner:北京盛康宁科技开发有限公司

Rolling method and device for strip steel tandem cold rolling

ActiveCN102513351BQuick calculationMake full use of production capacityMeasuring devicesTension/compression control deviceElectric machineryStrip steel

A rolling method and a device for strip steel tandem cold rolling belong to the technical field of metallurgical process control. Based on site conditions of the strip steel tandem cold rolling practical production, the rolling method and the device for the strip steel tandem cold rolling fully consider reasonability of optimization calculation of rolling force, select lowest energy consumption as an optimization goal, adopt a large number of constraint conditions in the practical rolling production process, utilize an improved particle swarm optimization (PSO) optimization algorithm to carry out optimal calculation on the basis of rolling mechanism relationship, and can quickly calculate out optimized rolling schedule information to avoid extra cost caused by lack of comprehensive consideration of experience rules. By means of the rolling method and the device for the strip steel tandem cold rolling, full play to the production capacity of the whole tandem cold rolling system can be given, product quality is improved, total power of a motor of a rolling mill is reduced simultaneously, and energy saving and consumption reduction are achieved accordingly.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com