Automatic poured bag stacking and grouping machine

A marshalling machine and bag-inverting technology, which is applied in the field of conveying equipment and automatic palletizing, can solve problems such as efficient operation of palletizers, automatic palletizing and bag-reversing marshalling machines, etc., so as to save production land resources, reduce site occupation, avoid Waste of equipment investment and waste of management resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

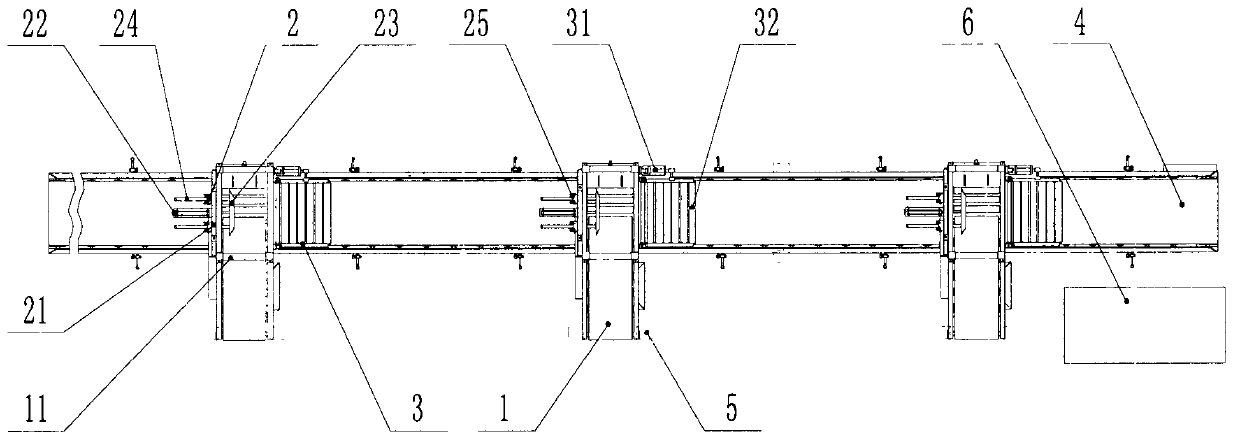

[0024] like figure 1 As shown, the automatic palletizing bag-inverting marshalling machine according to Embodiment 1 of the present invention consists of three groups of inlet conveying units 1, three bag-inverting devices 2, three bag-out devices 3, one group of outlet conveying units 4, an electric control cabinet 6 and Sensors 5 respectively arranged on the inlet conveying unit 1 and the outlet conveying unit 4 constitute. The entrance conveying unit 1 and the exit conveying unit 4 are installed at mutually perpendicular angles, the entrance conveying unit 1 is higher than the exit conveying unit 4, and the entrance conveying unit 1 is connected in a straight line with the rear end of the packaging conveyor; each group of entrance conveying units 1 is installed with A bag-inverting device 2 and a bag-out device 3, the bag-inverting device 2 is installed on the frame 11 above the side of the inlet conveyor unit 1; the bag-out device 3 is installed above the outlet conveyor u...

Embodiment 2

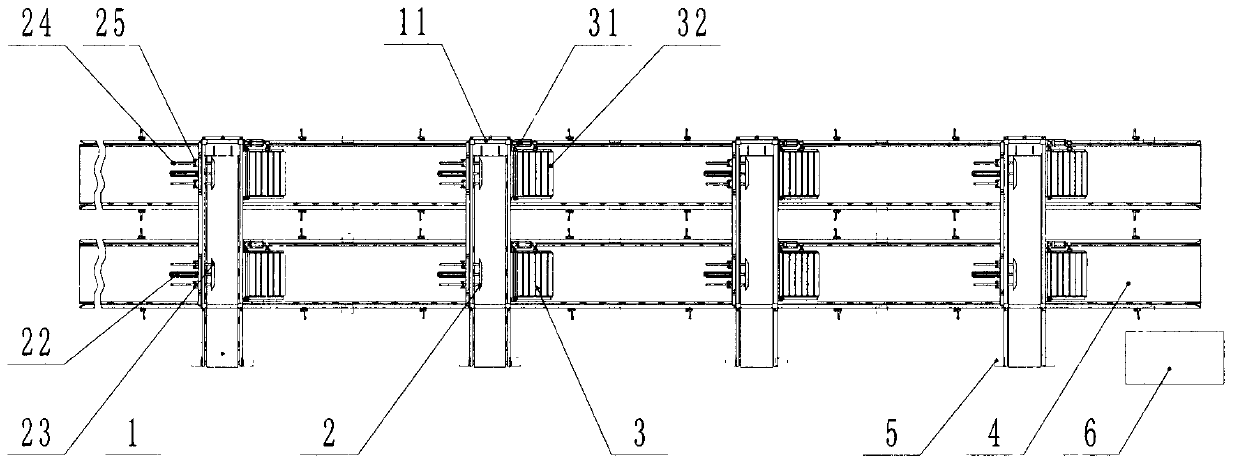

[0030] like figure 2 As shown, the automatic palletizing and bag-inverting marshalling machine of the second embodiment of the present invention consists of four groups of inlet conveying units 1, eight bag-reversing devices 2, eight bag-out devices 3, two groups of outlet conveying units 4, an electric control cabinet 6 and Sensors 5 respectively installed on the inlet conveying unit 1 and the outlet conveying unit 4 constitute. The entrance conveying unit 1 and the exit conveying unit 4 are installed at mutually perpendicular angles, the entrance conveying unit 1 is higher than the exit conveying unit 4, and the entrance conveying unit 1 is connected in a straight line with the rear end of the packaging conveyor; each group of entrance conveying units 1 is installed with Two bag-inverting devices 2 and two bag-out devices 3, the bag-inverting device 2 is installed on the side upper frame 11 of the inlet conveying unit 1, the bag-out device 3 is installed above the outlet co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com