A smart card production system and method

A production system and smart card technology, applied in the direction of instruments, calculations, and record carriers used by machines, can solve the problems of waste of resources, high labor intensity, and low production efficiency, and achieve reduced labor costs, high automation, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

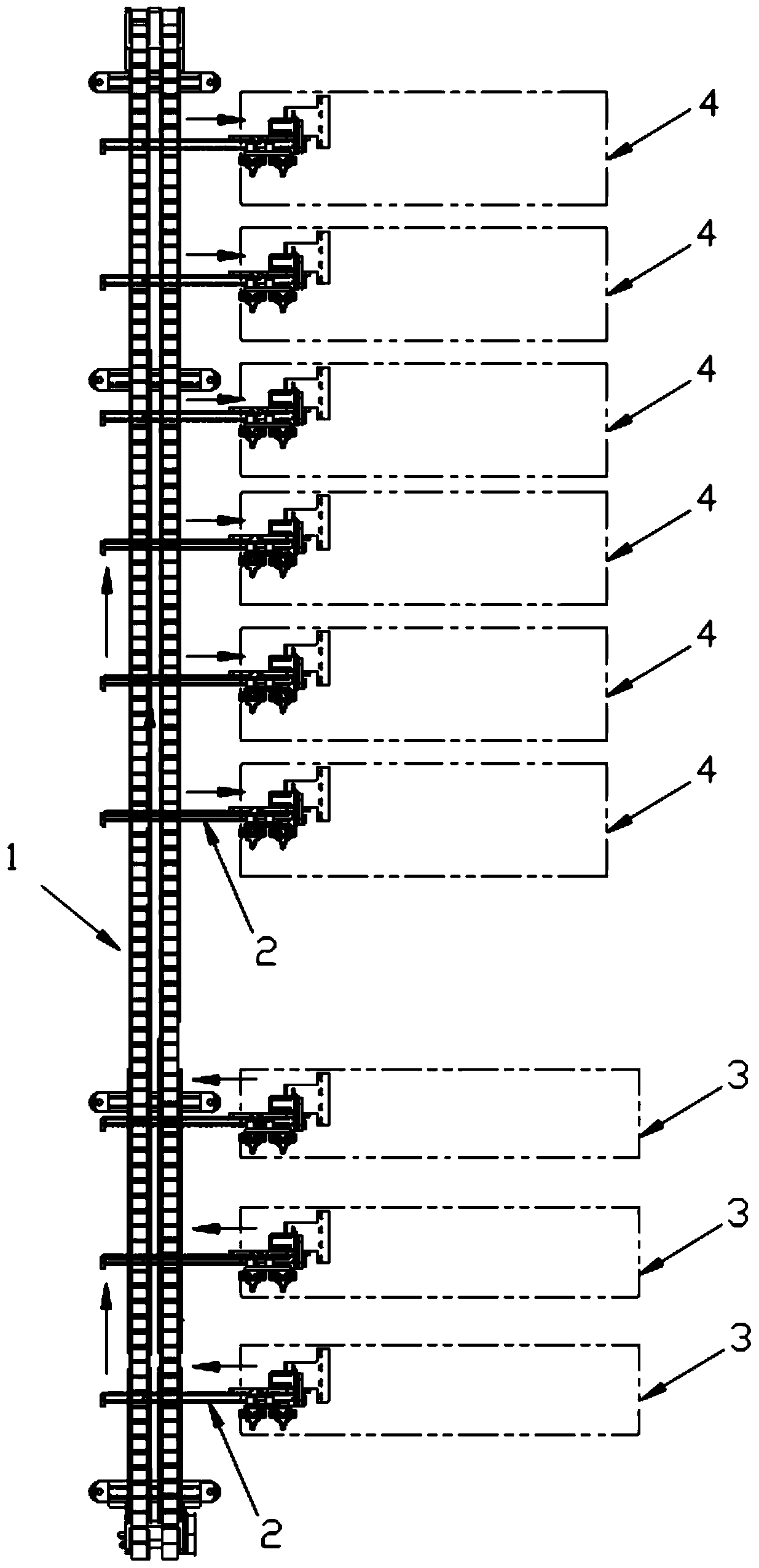

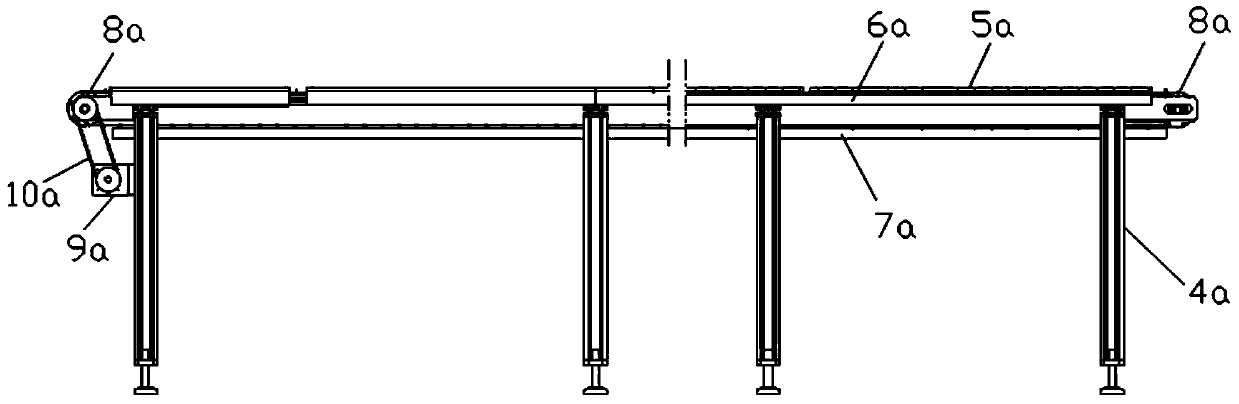

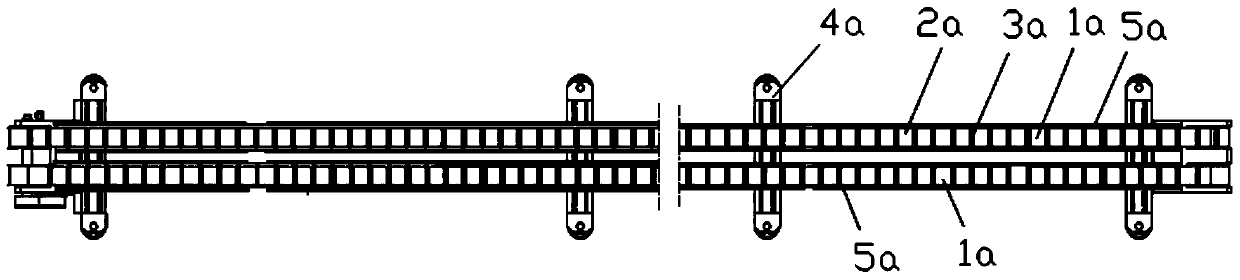

[0041] see Figure 1-Figure 10 , the smart card production system of the present invention comprises a card transport bus 1 and several sets of smart card processing equipment, the several sets of smart card processing equipment are arranged side by side, and these smart card processing equipment are divided into the upstream smart card processing equipment 3 and the upstream smart card processing equipment 3 that transport the card 11a to the card transport bus 1 Obtain the downstream smart card processing equipment 4 of card 11a from the card conveying bus 1; Card transport device 2 for card transport between the two.

[0042] see figure 1 , the upstream smart card processing equipment 3 is a smart card slot milling and thread-taking equipment, and the downstream smart card processing equipment 4 is a smart card butt-welding packaging equipment, through the combination of these two smart card processing equipment, the slot milling, thread picking, Butt welding and packagin...

Embodiment 2

[0065] The difference between this embodiment and embodiment 1 is that in this embodiment:

[0066] see Figure 11-Figure 14 , the card transport bus 1 is also provided with a card temporary storage device 5, the card temporary storage device 5 includes a card temporary storage slot 1c and a card transfer device 6c that transfers the card 11a from the card transport bus 1 to the card temporary storage slot 1c Wherein, the receiving end of the card temporary storage slot 1c is provided with a card guide plate 2c and a card push mechanism, the card guide plate 2c is inclined, and the card push mechanism includes a card push head 4c and a drive card push head 4c in the The card pushing power mechanism 3c that reciprocates in the length direction of the card temporary storage slot 1c, the card guide plate 2c is provided with a channel 2-1c that allows the card pushing head 4c to pass therethrough, and the card pushing power mechanism 3c is driven by a cylinder Composition; the ca...

Embodiment 3

[0070] The difference between this embodiment and embodiment 1 is that in this embodiment:

[0071] see Figure 15 , the suction head 2b is connected with the upper connection block 6-1b through a rotating mechanism, so that the suction head 2b can rotate the card during the process of carrying the card, usually by 90°, when the card is in the smart card processing equipment and the card transport bus 1 When the directions in the cards are inconsistent, use the rotating mechanism to rotate the card during transport; the rotating mechanism is composed of a rotating cylinder 14b, and the rotating mechanism 14b is fixed on the lower connecting block 6-2b through the connecting seat 15b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com