Method for controlling material flos of double-casting machine single roller way double-heating furnace

A control method, dual heating technology, applied in metal rolling and other directions, can solve problems such as uneven rhythm, reduced casting speed, overloaded operation of rolling line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

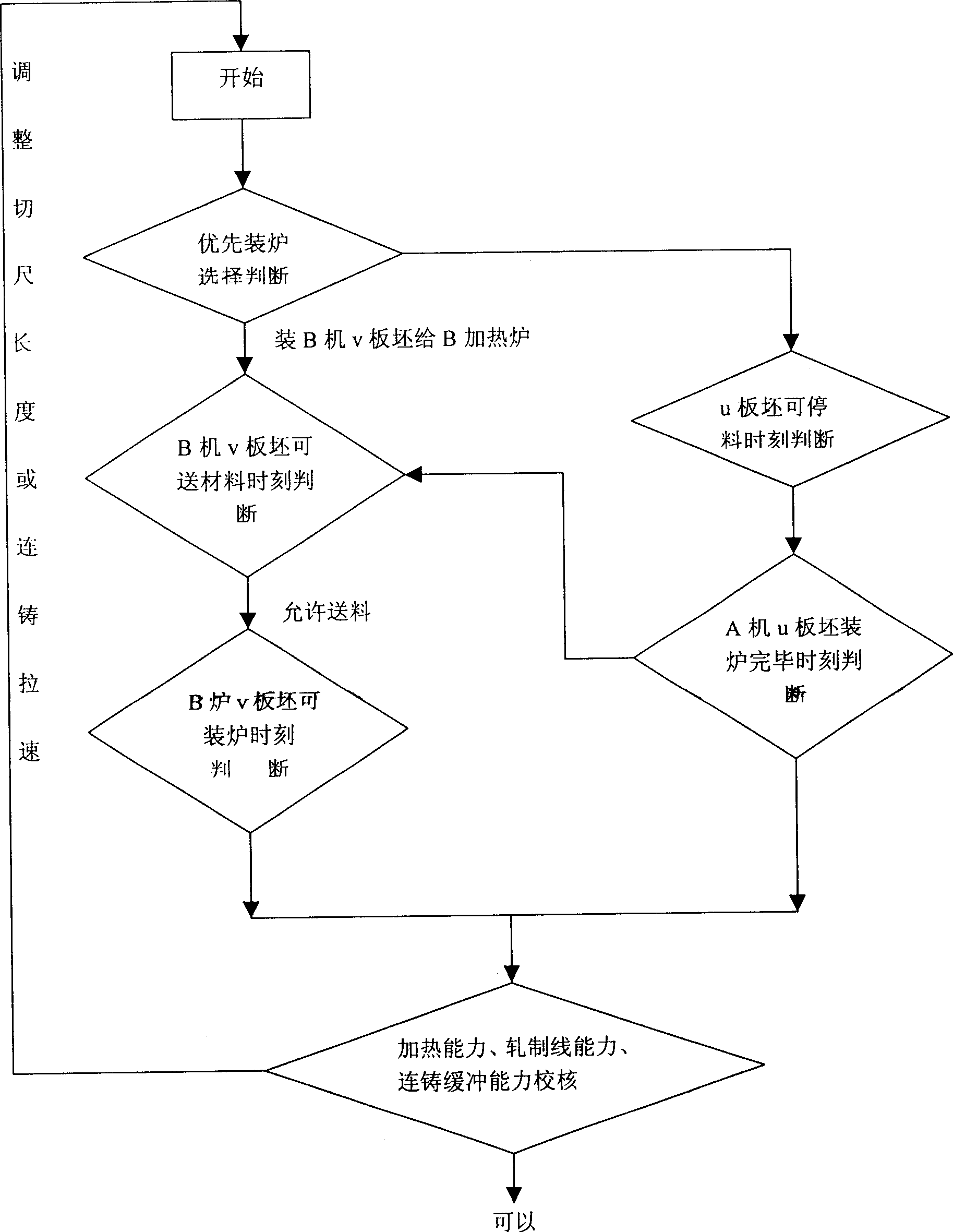

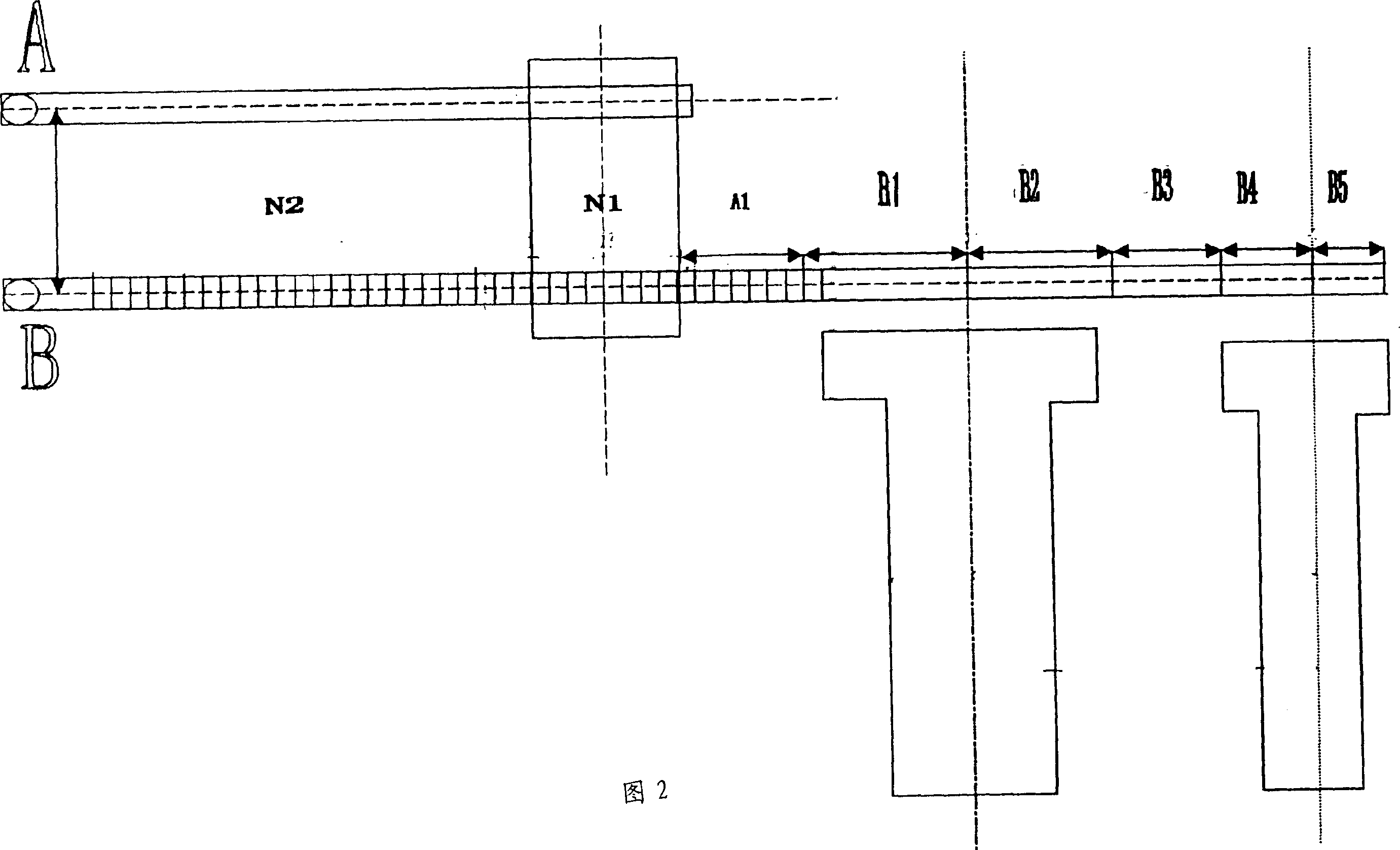

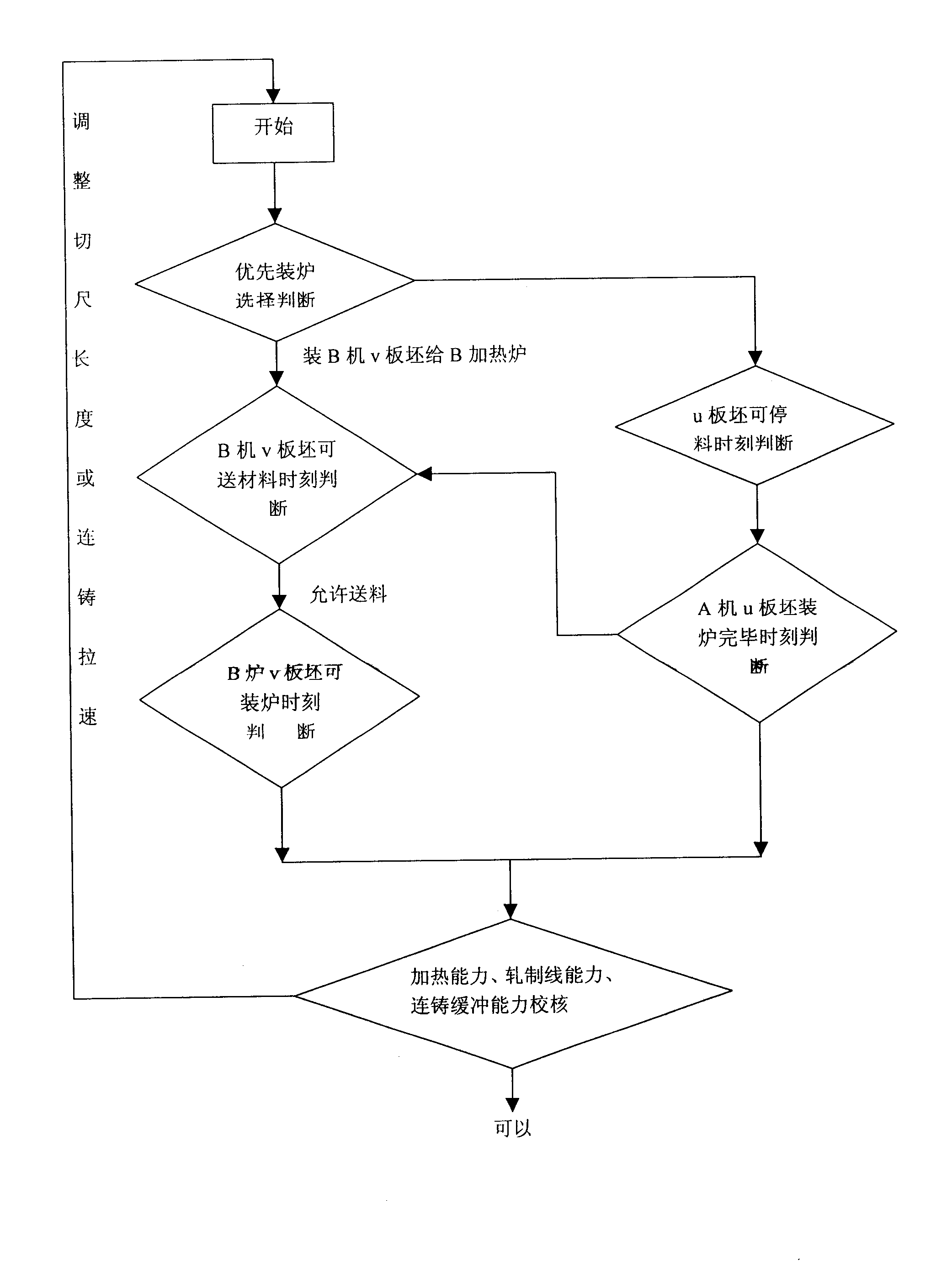

[0036] An example of the specific implementation of the present invention will be described below with reference to the accompanying drawings.

[0037] According to the logistics control method of twin continuous casting machines with single roller table and double heating furnaces of the present invention, when casting machines A and B are respectively supplying two heating furnaces of A and B, furnace loading is selected preferentially, and the time of feeding can be compared and the time of furnace loading can be compared. Comparing and pumping steel moment calculations,

[0038] Suppose: u is the uth slab of the current block of A casting machine, v is the vth slab of the current block of B casting machine,

[0039] T a is the casting time of u slab; Ta = la na , l a is the slab length of line A (10.8~15.6m), n a is the casting speed of line a (2~3.3m / min),

[0040] T b Casting time for v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com