Optimization method of rolling schedule of non-reversible aluminum strip cold rolling mill

A technology of rolling schedule and optimization method, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., and can solve the problems of rolling schedule optimization deviating, consideration of many constraints of rolling mill, and insufficient consideration of constraints of process conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

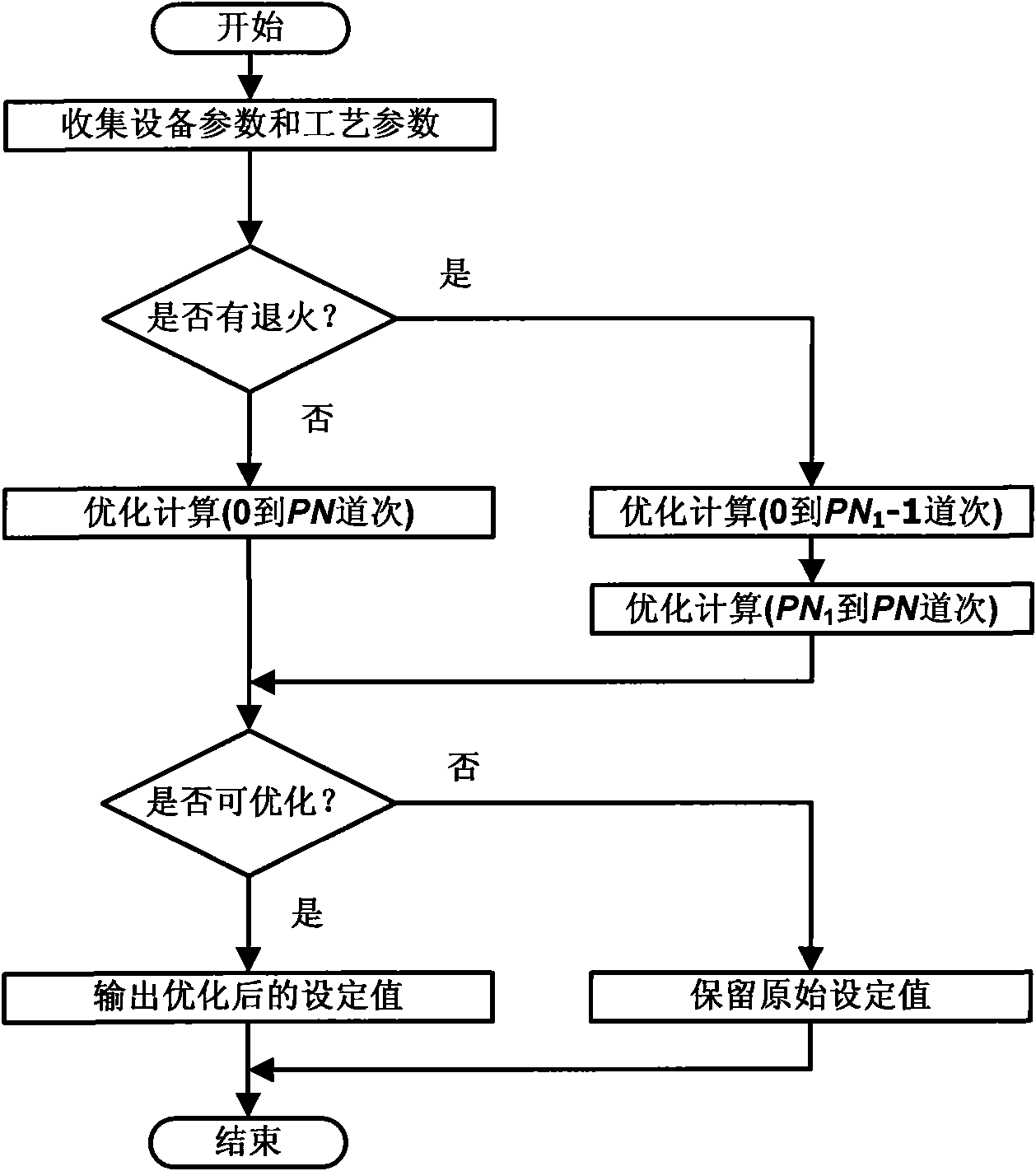

[0078] The method for optimizing the rolling schedule of the irreversible aluminum strip cold rolling mill of the present invention, such as figure 1 As shown, it specifically includes the following steps:

[0079] (1) Collect the equipment parameters and process conditions of the aluminum strip cold rolling mill. The equipment parameters and process conditions include: diameter of the upper and lower work rolls, diameter of the upper and lower backup rolls, rated power of the main motor, maximum rolling torque, maximum Rolling speed, minimum rollable thickness and maximum reduction rate;

[0080] (2) Determine strip specifications and finished product requirements, strip specifications and finished product requirements include: raw material material, raw material width, raw material thickness, raw material convexity, finished product thickness and finished product convexity;

[0081] (3) Collect the parameters of the actual use rules, the parameters of the actual use rules i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com