Photovoltaic glass deep processing tampering furnace parallel production control system

A photovoltaic glass, production control technology, applied in glass tempering, general control system, control/regulation system, etc., can solve the problems of low production efficiency, increased production cost, decreased output, etc., to avoid the influence of human factors, reduce Labor cost, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

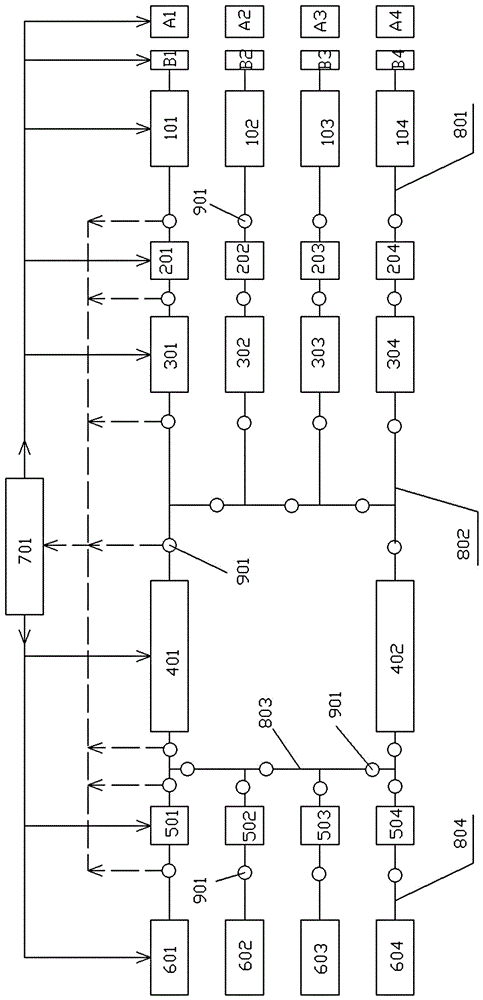

[0017] Such as figure 1 As shown, the present invention provides a photovoltaic glass deep-processing tempering furnace parallel production control system, including four edging lines, two tempering lines and four unloading lines. The first edging line is arranged by the first glass stacker A1 and the A glass loading machine B1, a first edging machine 101, a first front cleaning machine 201 and a first coating machine 301 are constituted, and the second edging line is composed of the second glass stacking machine A2 and the second glass loading machine arranged in sequence B2, the second edging machine 102, the second pre-cleaning machine 202 and the second coating machine 302 are constituted. The third edging line consists of the third glass stacker A3, the third glass loading machine B3, and the third edging machine arranged in sequence. The edging machine 103, the third front cleaning machine 203 and the third coating machine 303 are constituted. The fourth edging line consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com