Device and method for producing bags from pieces of tubing

A technology of hose fittings and hoses, applied in the field of bag manufacturing, which can solve the problems of large spacing and incomplete utilization of production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

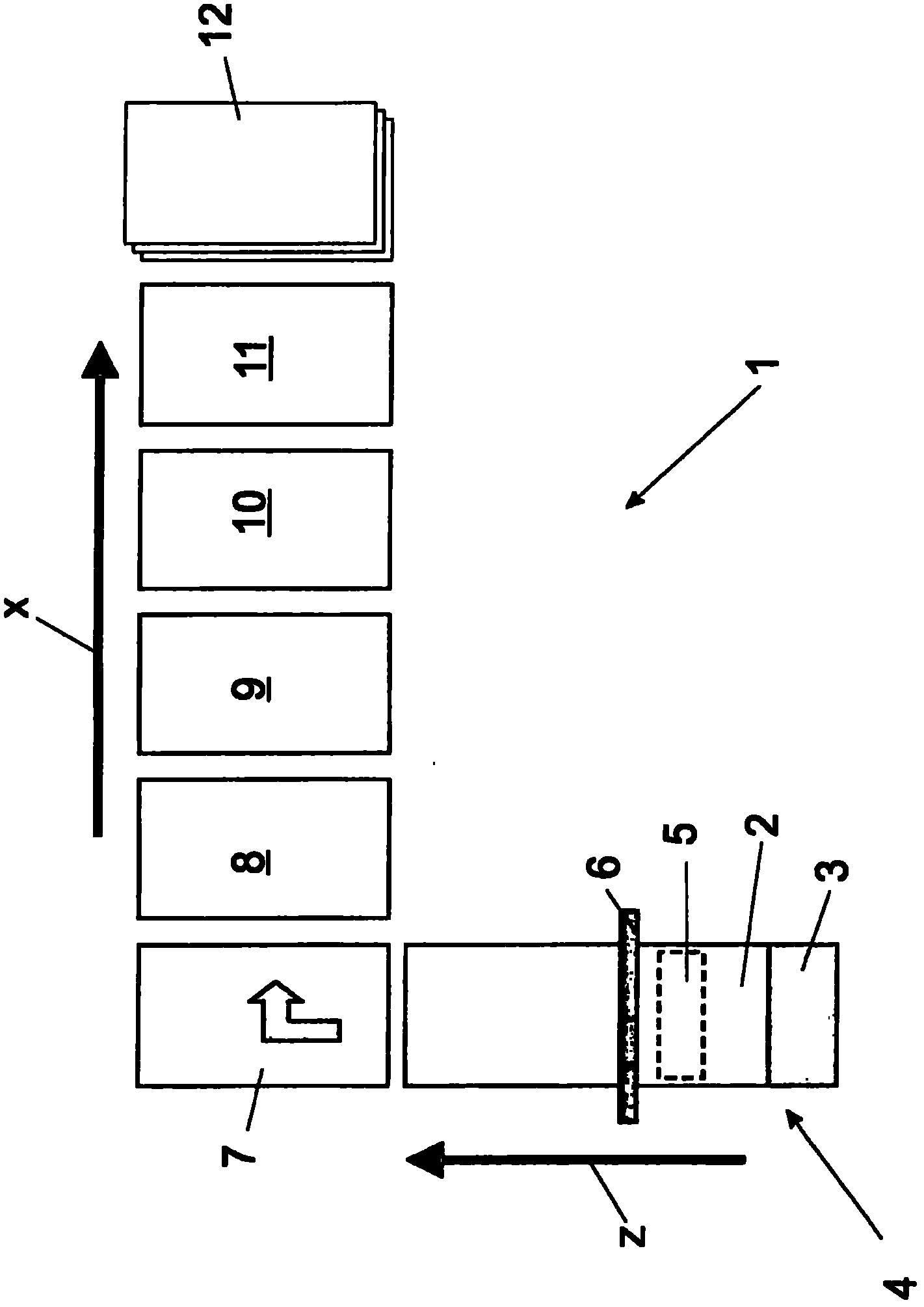

[0037] figure 1 The individual steps, as carried out in the bag manufacturing device 1 , are schematically shown for processing the textile tube into a bag.

[0038] First the textile hose 2 is fed into the bag manufacturing device 1 . This is advantageously carried out by unrolling the textile hose forming the coil 3 in the unrolling device 4 . Subsequently, the hose 2 is so-called opened in the opening station 5 . In this case, the fabric hose is guided around an internal tool which separates the two layers from one another so that the layers are separated if they are bonded to one another in one of the production steps of the hose. Only when the layers are separated can it be ensured that subsequent production steps can be carried out as specified. Subsequently, the mutually separated material layers of the hose overlap one another again.

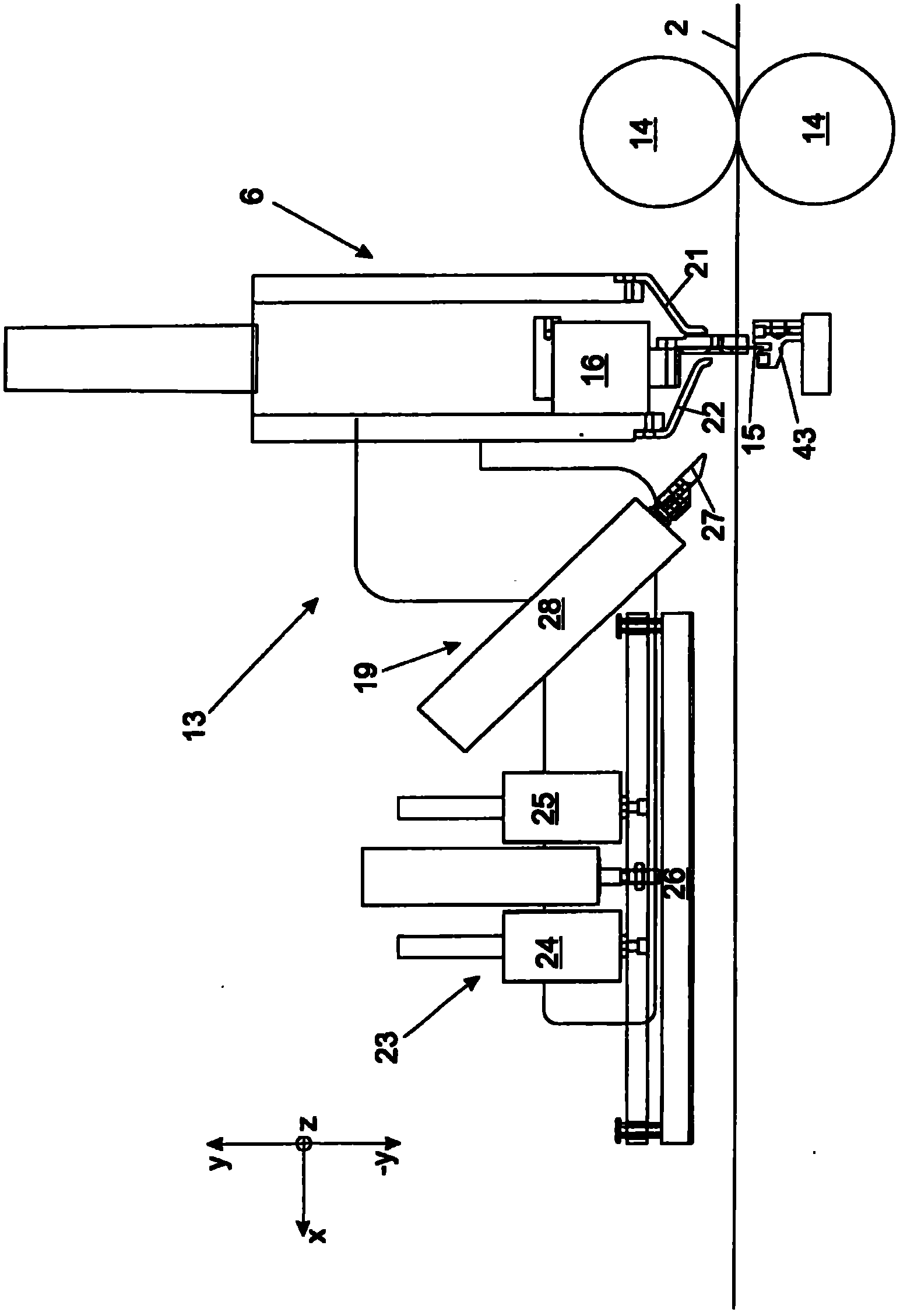

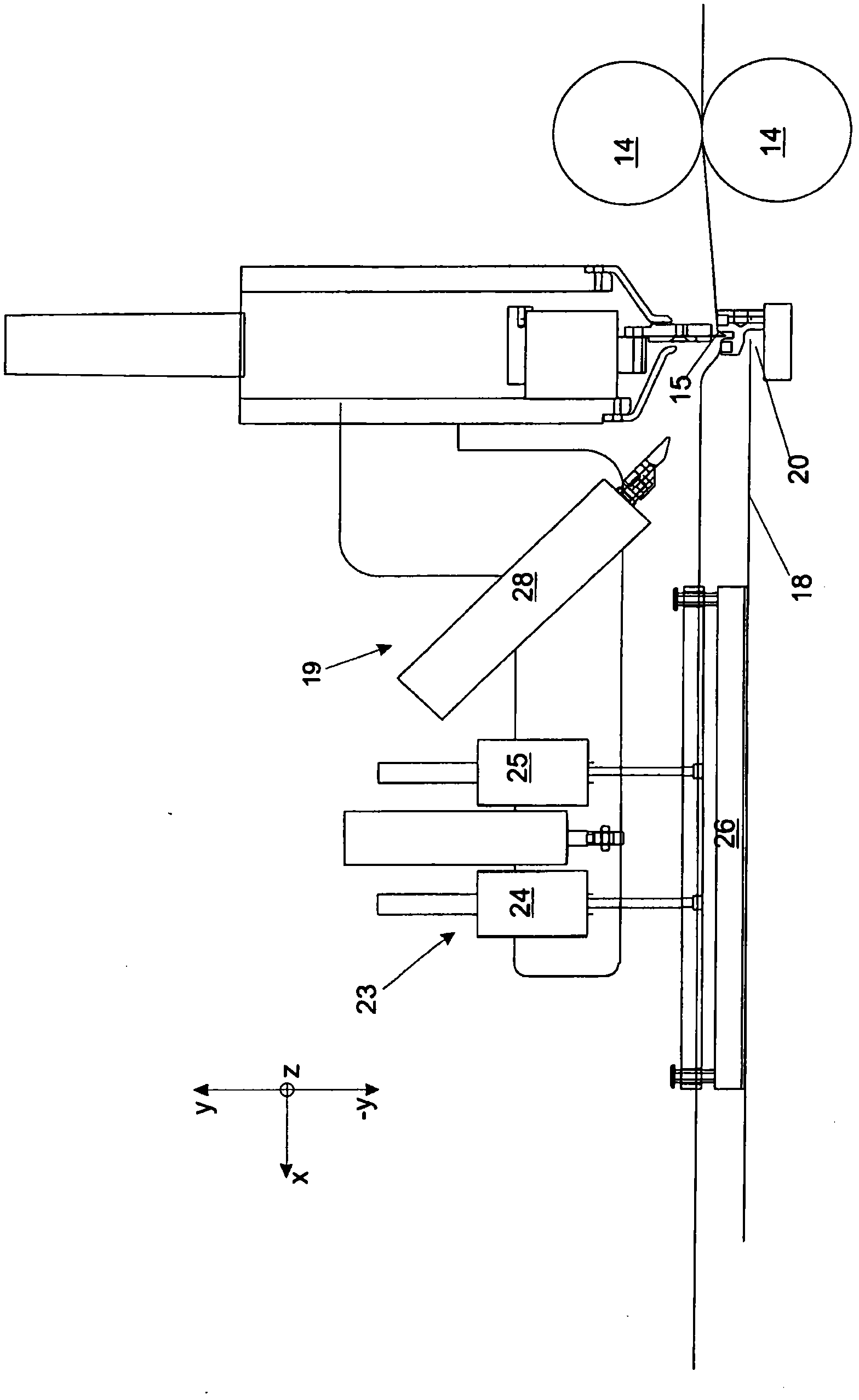

[0039] The textile hose is now fed to the transverse cutting device 6 , which divides the textile hose into individual hose parts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com