Automatic stacking, conveying and marshalling system

A palletizing and automatic technology, applied in the field of automatic palletizing, conveying and marshalling systems, can solve problems such as automatic palletizing, conveying and marshalling equipment for efficient operation of palletizers that have not yet been found, and achieve saving production land resources, reducing site occupation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

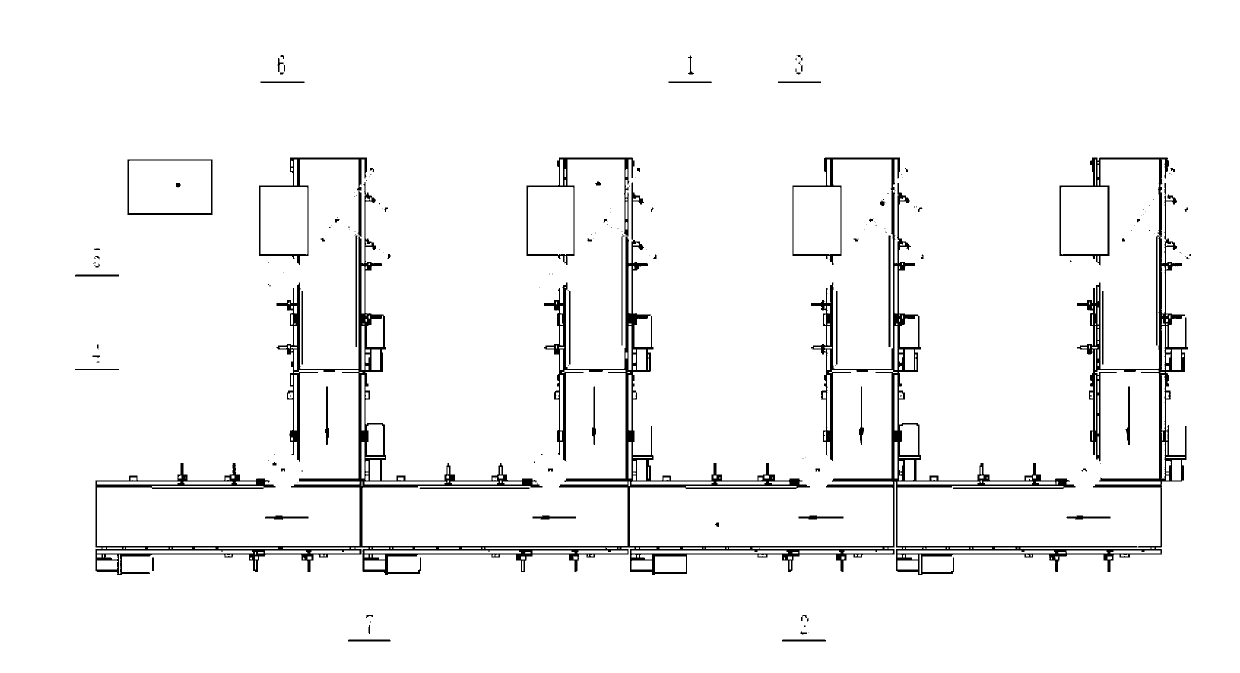

[0019] Such as figure 1 As shown, the automatic palletizing conveying marshalling system of the present invention consists of 4 groups of parallel-arranged inlet conveyor units 1, a group of outlet conveyor units 2, four bag-reversing devices 3, four guide devices 4, several sensors 5 and electric control The cabinet consists of 6. The outlet conveying unit 2 is vertically installed on the output ends of four groups of import conveying units 1, and the conveying working surfaces of the export conveying unit and the import conveying unit are on the same plane; The connecting corner of the export conveyor unit 2 is used to guide the turning of the goods; the sensors 5 are respectively installed on the racks of the import conveyor unit 1 and the export conveyor unit 2; the electric control cabinet 6 is connected with the import conveyor unit 1, The outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com