Rolling method and device for strip steel tandem cold rolling

A technology for continuous cold rolling and strip steel, which is applied in rolling mill control devices, metal rolling, length measuring devices, etc., and can solve problems such as differences, constraints, and insufficient consideration of experience constraints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

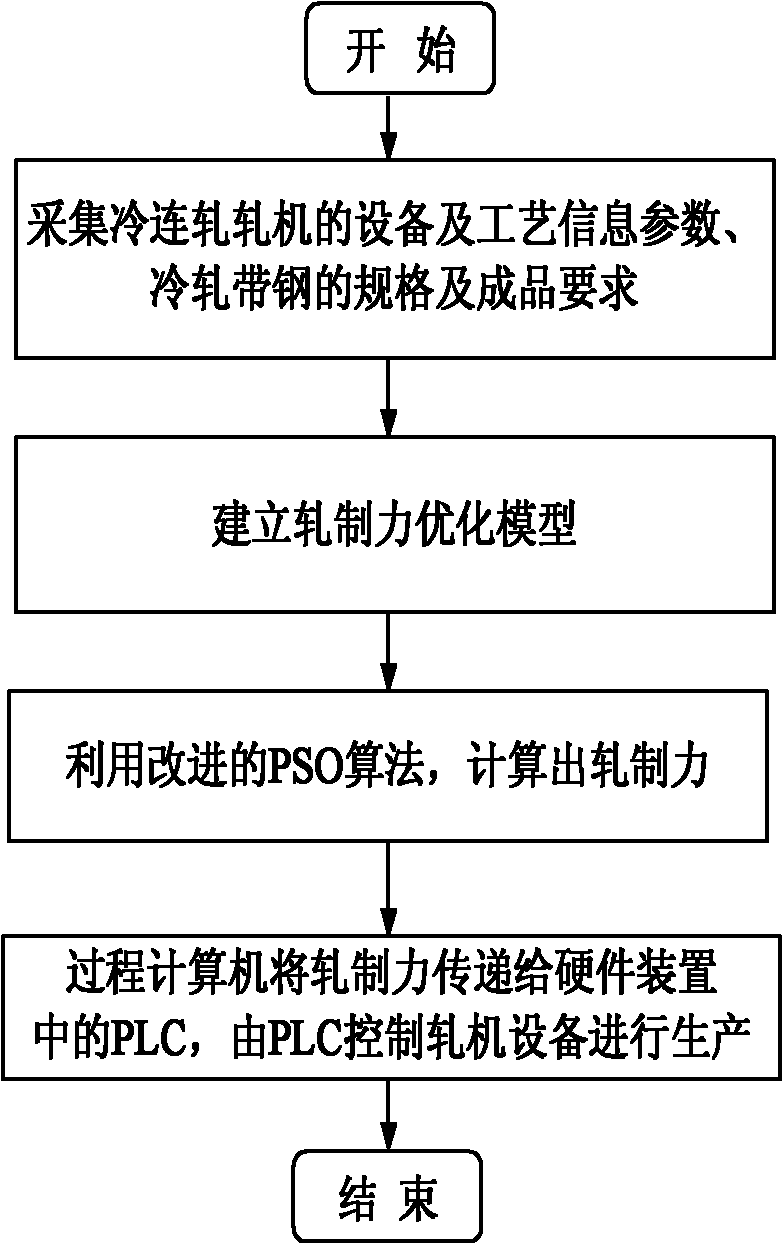

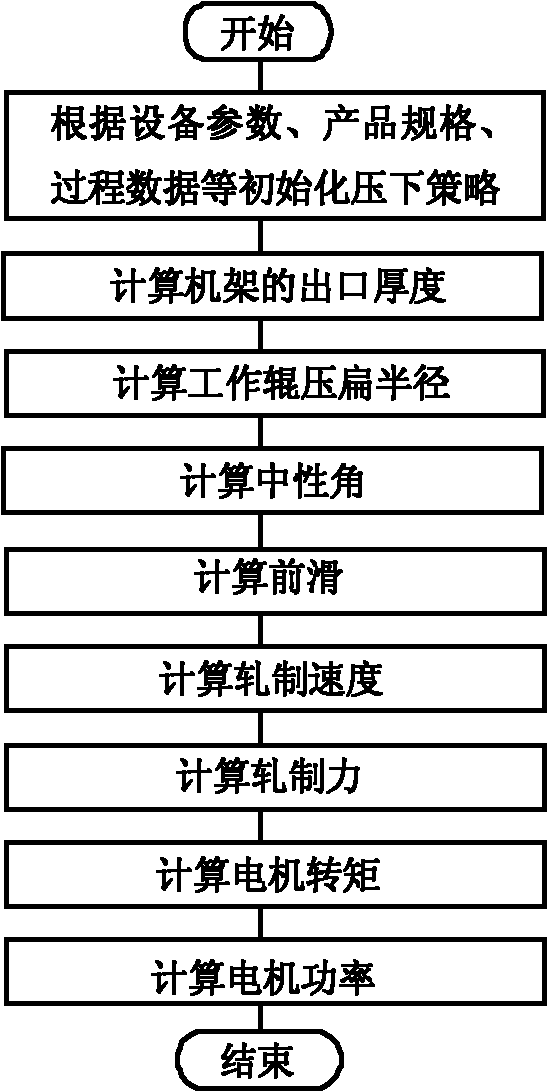

[0110] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

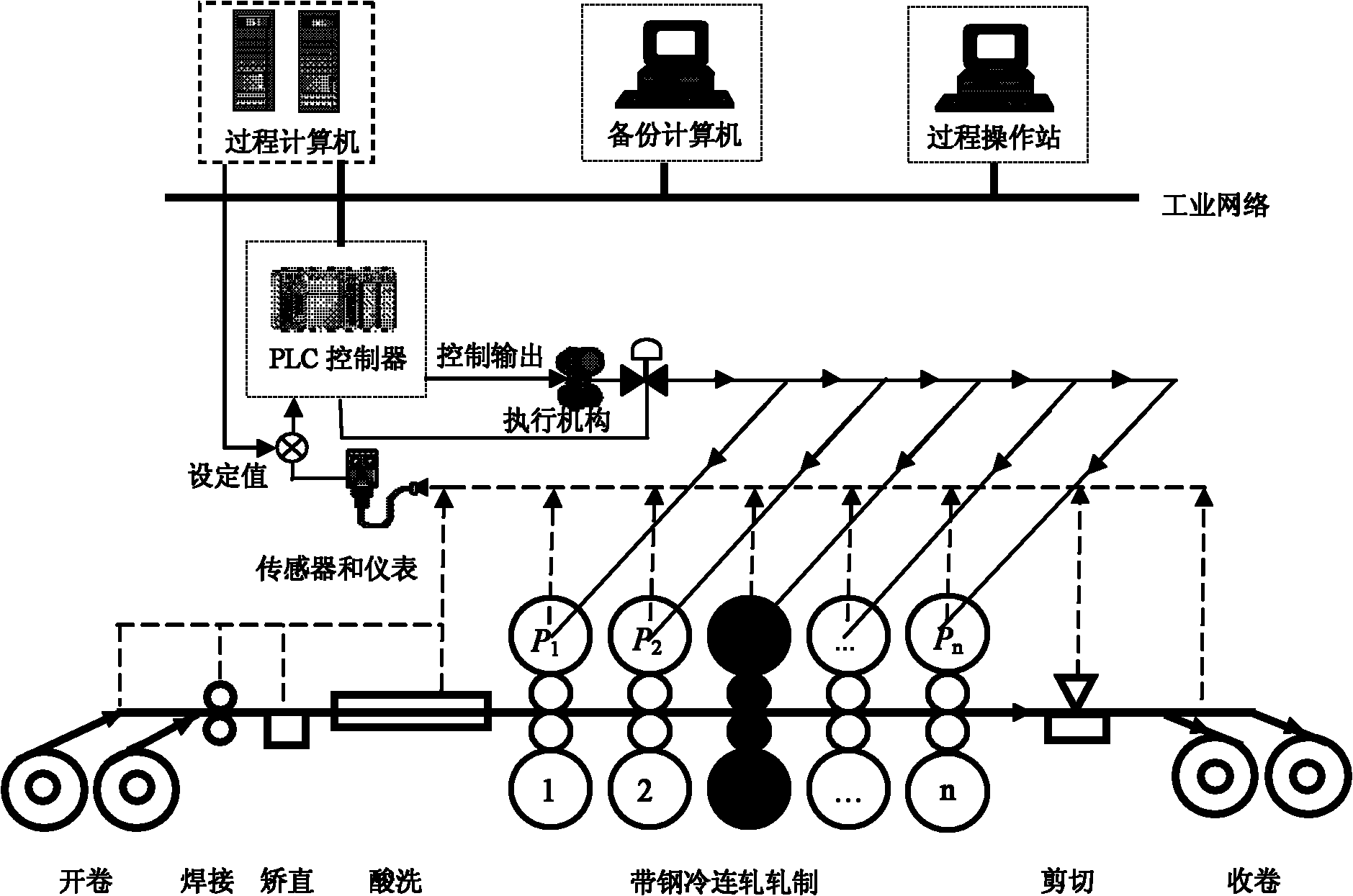

[0111] The present embodiment adopts a 2030mm five-stand strip steel continuous cold rolling mill in a steel plant.

[0112] Step 1: Collect the equipment parameters and process conditions of the cold tandem rolling mill, the specifications of the cold-rolled strip steel and the parameter data required for the finished product;

[0113] (1) Collect the equipment parameters and process conditions of the cold tandem rolling mill: the system in the present embodiment is made up of five groups of stands, numbered 1-5, and the number of rolls of each group of stands is 4, their working roll diameters and The diameters of the backup rolls are different, and the specific values are shown in Table 1:

[0114] Table 1 Technical parameters and process parameters of cold tandem rolling

[0115]

[0116] It can be seen from Table 1 that the maximum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com