Metal card clothing of carding machine

A metal card clothing and carding technology, which is applied in deburring devices, textiles and papermaking, fiber treatment, etc., can solve the problem of poor trash capacity of metal card clothing, and achieve improved trash capacity, good tooth tip strength, and guaranteed The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described below in conjunction with the drawings.

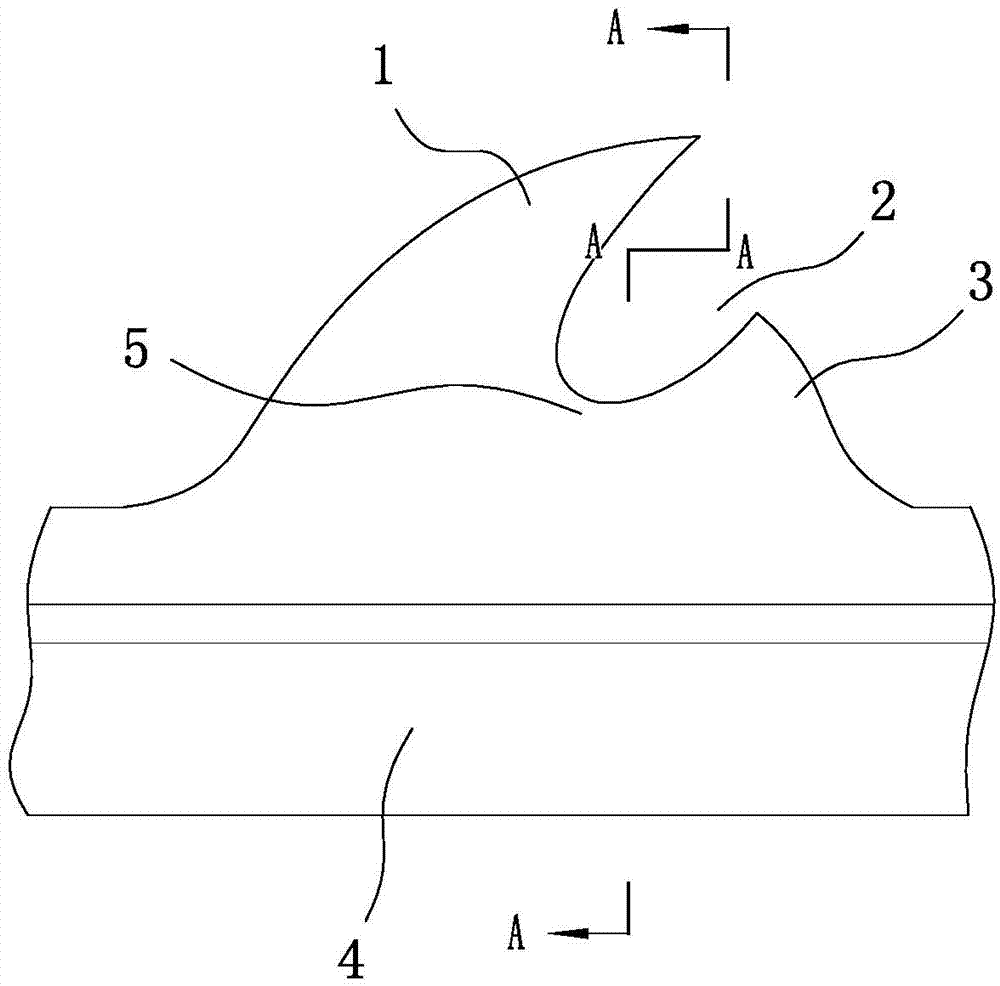

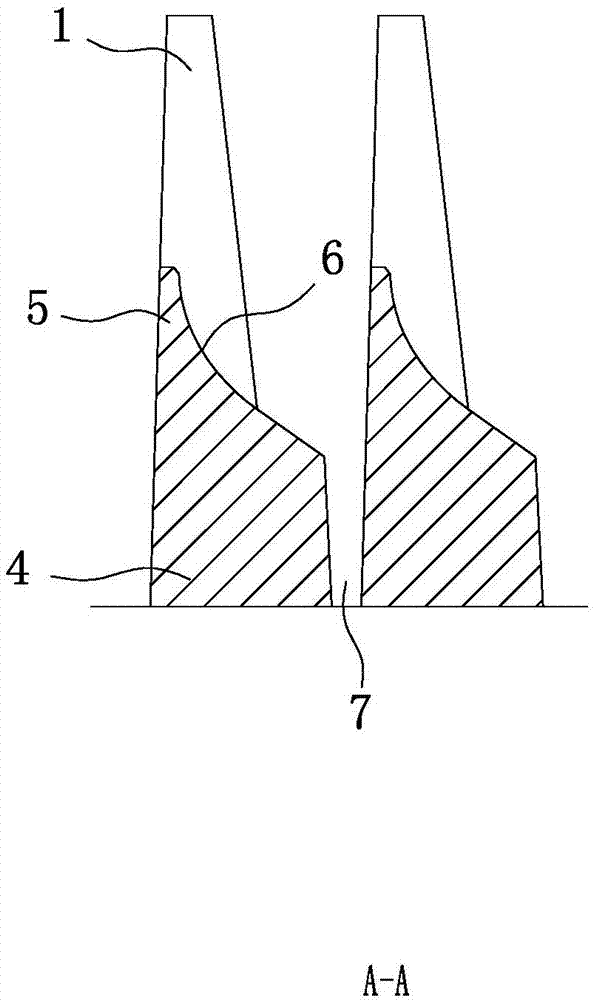

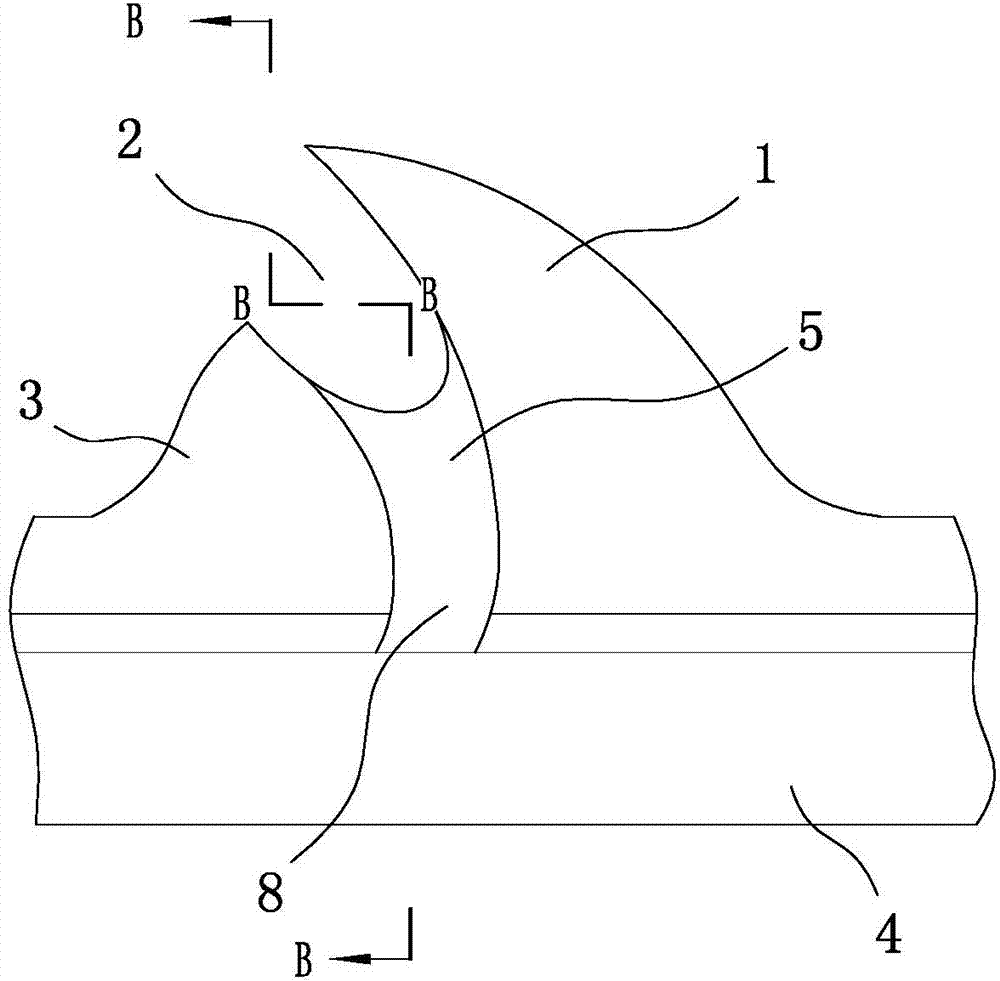

[0016] Such as Figure 1 to Figure 4 As shown, the present invention includes a base 4 on which main teeth 1 are evenly distributed. The front part of each main tooth 1 is provided with auxiliary teeth 3, and there is a gap 2 between the main tooth 1 and the auxiliary tooth 3; the main tooth 1 is Arc-backed teeth with arc working surface, this kind of tooth shape has good combing effect and strong tooth tip strength; the auxiliary tooth 3 is a mountain-shaped tooth, this kind of tooth shape basically has no combing effect, mainly to reduce the main tooth 1 when combing hair The effective working tooth height can reduce the damage to the wool fiber. Therefore, the tooth height of the auxiliary tooth 3 is lower than that of the main tooth 1. The main tooth 1 and the auxiliary tooth 3 are connected by a transition plate 5. One side of the transition plate 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com