Nonwoven Cards for Spinning Absorbent Cotton

A technology of non-woven fabrics and spinning absorbent cotton, which is applied in textiles and papermaking, fiber treatment, deburring devices, etc. It can solve the problem that the carding mechanism cannot achieve a good effect of removing impurities, and achieve a reasonable setting of the line speed and production efficiency. High efficiency, basically consistent vertical and horizontal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

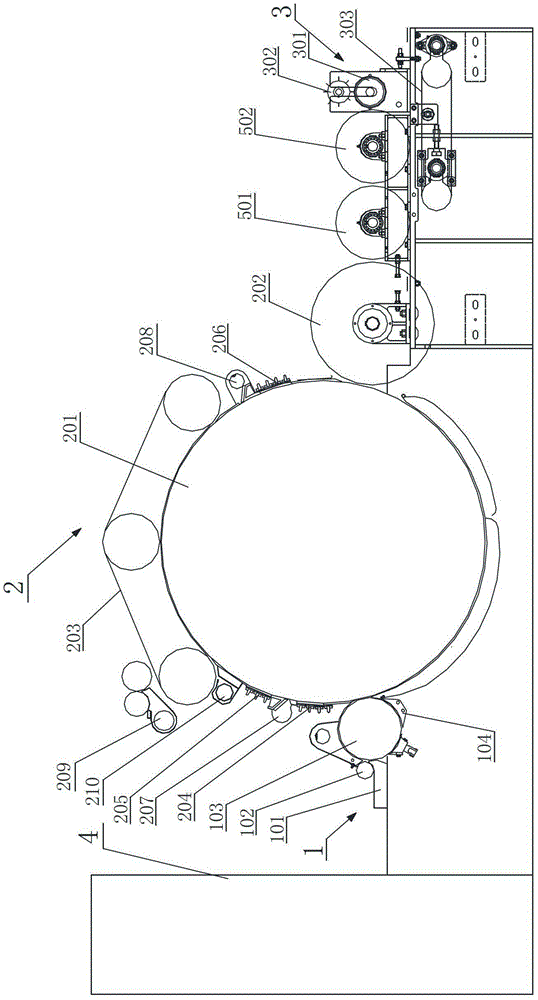

[0017] to combine figure 1 As shown, the nonwoven carding machine for spinning absorbent cotton includes a feeding mechanism 1, a carding mechanism 2 and a stripping mechanism 3.

[0018] The feeding mechanism 1 includes a cotton feeding part and a lickering roller 103, and the cotton feeding part is located in front of the lickering roller, including a cotton feeding board 101 and a cotton feeding roller 102, and an automatic feeding box is arranged in front of the cotton feeding board 4. A pre-carding plate 104 is arranged under the rear part of the depilation roller 103 to play a preliminary carding effect.

[0019] The carding mechanism 2 includes a cylinder 201 and a doffer 202, the cylinder is located in front of the doffer and is connected with the doffer, a movable cover 203 is arranged above the cylinder, and a first front fixed cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com