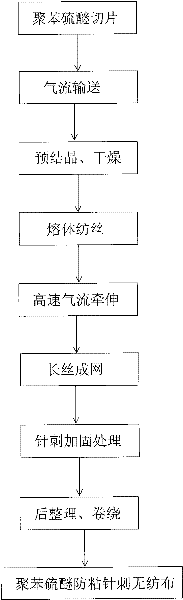

Method for preparing polyphenylene sulfide spun-bonded needle punched non-woven fabrics

A technology of needle-punched non-woven fabrics and polyphenylene sulfide, which is applied in the preparation process of needle-punched non-woven fabrics and the field of preparation of polyphenylene sulfide spun-bonded needle-punched non-woven fabrics, which can solve the problem of poor air permeability and high needle-punched density and other problems, to achieve the effect of high production efficiency, consistent vertical and horizontal strength, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

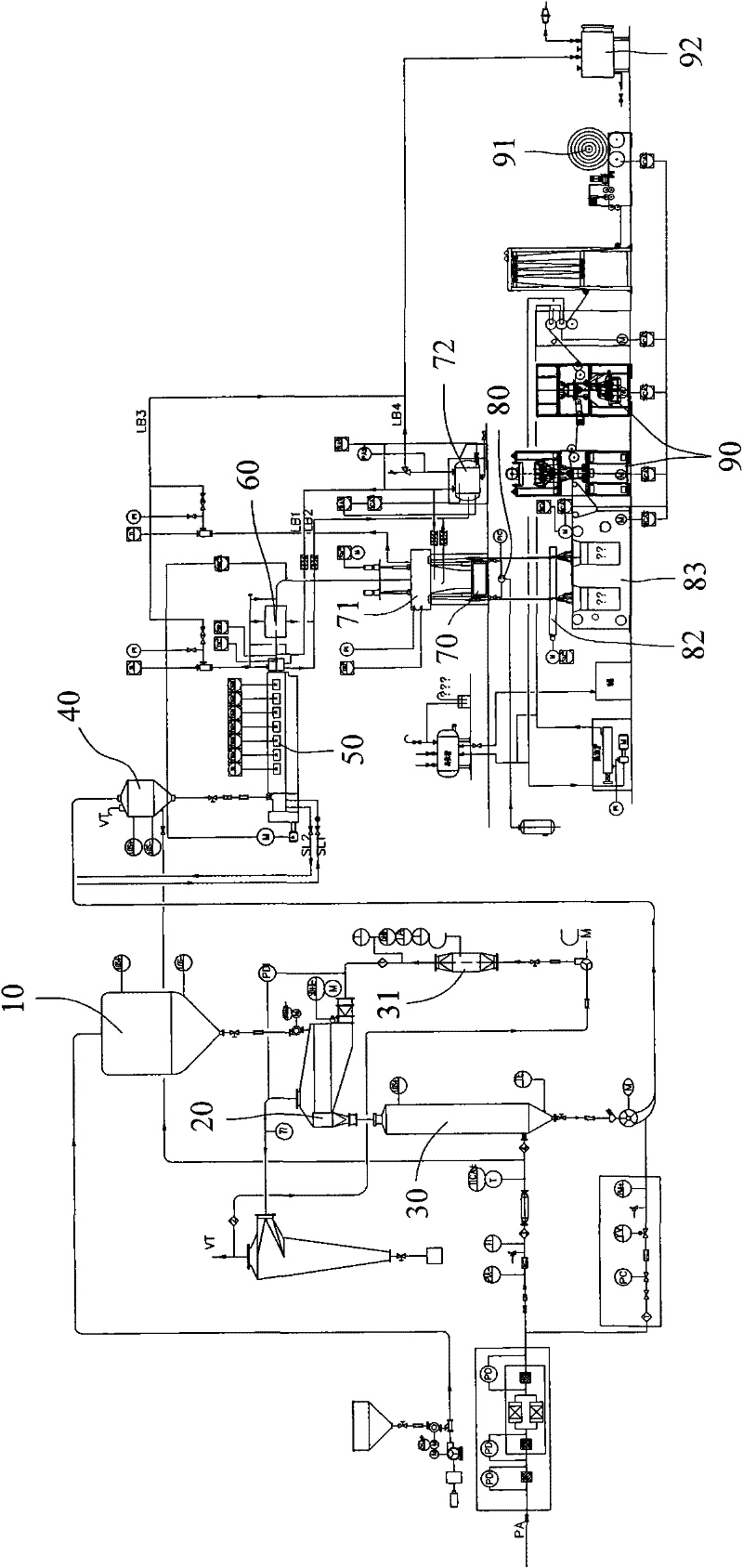

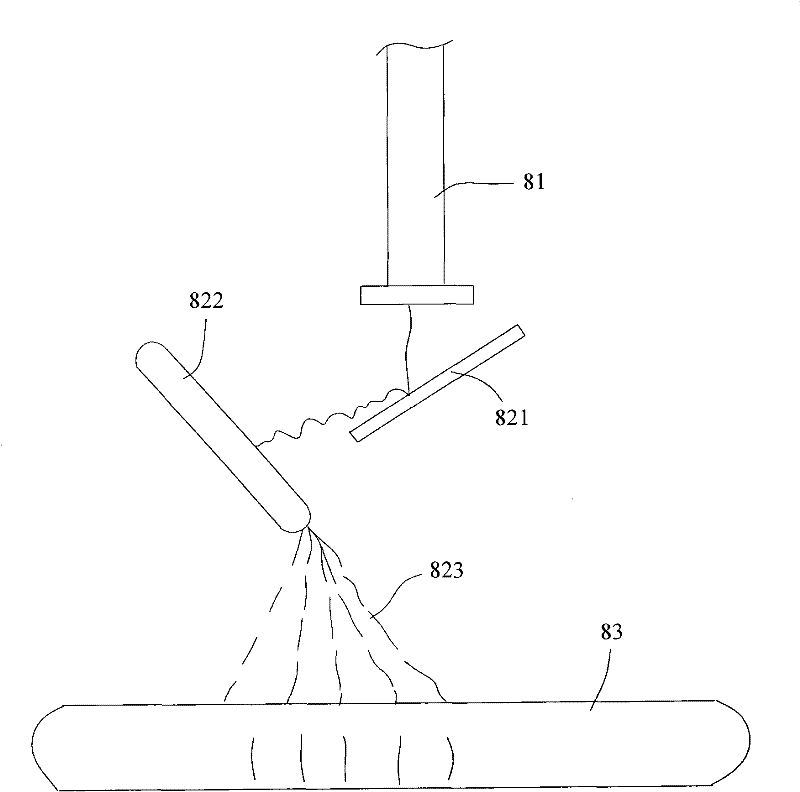

[0051] 300kg polyphenylene sulfide slices (melt index: 105-165g / 10min) are transported to the pre-crystallizer by air flow for pre-crystallization, the temperature set in the pre-crystallizer is 110-160°C, and the pre-crystallized slices are dried in a drying tower After treatment, it becomes a dry chip with a moisture content of 20-60ppm, and then it is extruded, melted, and metered. The speed of the metering pump is 15rpm, and it is extruded from the small hole of the spinneret under the action of pressure and gravity; Under the action of side blowing, the slow-cooled melt stream becomes a fiber filament with certain mechanical properties, and the fiber fineness is 3D. After passing through the drafting process of the air drafter, the fiber has excellent mechanical properties; the fiber bundle Under the action of the spinning device, a uniform fiber web is laid, and under the conveyance of the web forming machine, it enters the acupuncture machine for processing; the polyphen...

Embodiment 2

[0053] 500kg of polyphenylene sulfide slices (melt index: 105-165g / 10min) are transported to the pre-crystallizer by air flow for pre-crystallization. The temperature set in the pre-crystallizer is 110-160°C, and the pre-crystallized slices are dried in a drying tower After treatment, it becomes a dry chip with a moisture content of 20-60ppm, and then extrudes, melts, and measures. The speed of the metering pump is 19rpm, and it is extruded from the small hole of the spinneret under the action of pressure and gravity; Under the action of side blowing, the slow-cooled melt stream becomes a fiber filament with certain mechanical properties, the fiber fineness is 6D, and then through the drafting process of the air drafter, the fiber has excellent mechanical properties; the fiber bundle Under the action of the spinning device, a uniform fiber web is laid, and under the conveyance of the web forming machine, it enters the acupuncture machine for processing; the polyphenylene sulfid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com