High-tension medical non-woven fabric

A non-woven, high-strength technology, used in medical science, non-woven fabrics, textiles and papermaking, etc., can solve problems such as unfavorable mass production, easy dissolution of antibacterial agents, and unsustainable antibacterial properties, and achieve good mechanical properties and Self-cleaning properties, excellent antibacterial properties and mechanical properties, effect of long-lasting antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

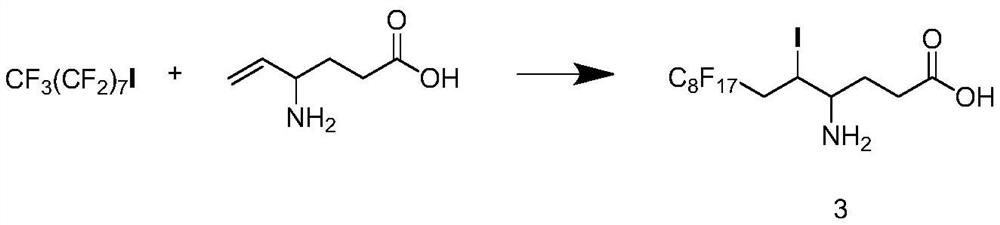

[0049] This embodiment prepares a kind of modified carbon fiber, the steps are as follows:

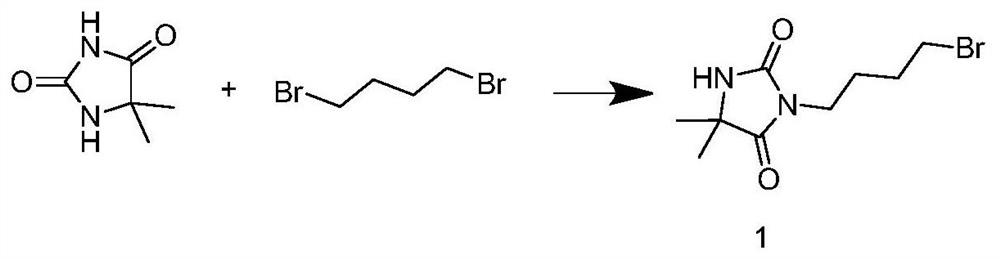

[0050] Step 1. Add 1.28g of 5,5-dimethylhydantoin and 100mL of acetone into a three-necked flask, then add 4.12g of potassium carbonate to reflux for 30min, add 8.12g of 1,4-dibromobutane, and continue to reflux for 4h. After the reaction, filter while hot to remove the inorganic salts, collect the filtrate, and distill the solvent under reduced pressure. Phase, distillation under reduced pressure, obtains intermediate 1;

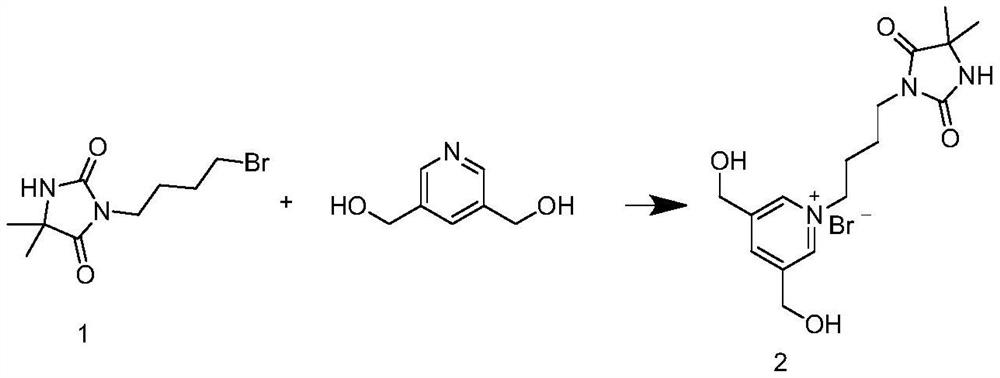

[0051] Step 2. Add 1mmol of 3,5-pyridinedimethanol and 80mL of ethanol solution with a mass fraction of 40% into a three-necked flask, stir and heat up to 40°C, add 10mL of ethanol solution of intermediate 1, heat up to 45°C, and keep the temperature for 7h. After the reaction, ethanol was distilled off under reduced pressure, washed with deionized water and filtered, and the filtrate was evaporated to dryness under reduced pressure to obtain intermediate 2. The et...

Embodiment 2

[0059] This embodiment prepares a kind of modified carbon fiber, the steps are as follows:

[0060] Step 1. Add 1.28g of 5,5-dimethylhydantoin and 100mL of acetone into a three-necked flask, then add 4.82g of potassium carbonate to reflux for 30min, add 8.23g of 1,4-dibromobutane, and continue to reflux for 4.5h , after the reaction, filter while hot to remove inorganic salts, collect the filtrate, distill under reduced pressure to remove the solvent, and the distillation product is separated and purified by chromatographic column, using a mixture of ethyl acetate and petroleum ether with a volume ratio of 2:5 as the eluent, collect The organic phase was distilled under reduced pressure to obtain intermediate 1;

[0061] Step 2. Add 1mmol of 3,5-pyridinedimethanol and 90mL of ethanol solution with a mass fraction of 40% into a three-necked flask, stir and heat up to 40°C, add 10mL of ethanol solution of intermediate 1, heat up to 45°C, and keep the temperature for 7.5h After ...

Embodiment 3

[0069] This embodiment prepares a kind of modified carbon fiber, the steps are as follows:

[0070] Step 1. Add 1.28g of 5,5-dimethylhydantoin and 100mL of acetone into a three-necked flask, then add 5.35g of potassium carbonate to reflux for 30min, add 8.78g of 1,4-dibromobutane, and continue to reflux for 5h. After the reaction, filter while hot to remove the inorganic salts, collect the filtrate, and distill the solvent under reduced pressure. Phase, distillation under reduced pressure, obtains intermediate 1;

[0071] Step 2. Add 1 mmol of 3,5-pyridinedimethanol and 100 mL of ethanol solution with a mass fraction of 40% into a three-necked flask, stir and heat up to 40°C, add 10mL of ethanol solution of intermediate 1, heat up to 45°C, and keep the temperature for 8h. After the reaction, ethanol was distilled off under reduced pressure, washed with deionized water and filtered, and the filtrate was evaporated to dryness under reduced pressure to obtain intermediate 2. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretching force | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com