Supporting structure for movable cover plate

A movable cover and supporting technology, which is applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems affecting the movable cover, the unclean removal of cover flowers, and the effect of fiber carding, etc., to improve Product quality, enhance the carding effect, overcome the effect that cannot be adjusted by itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

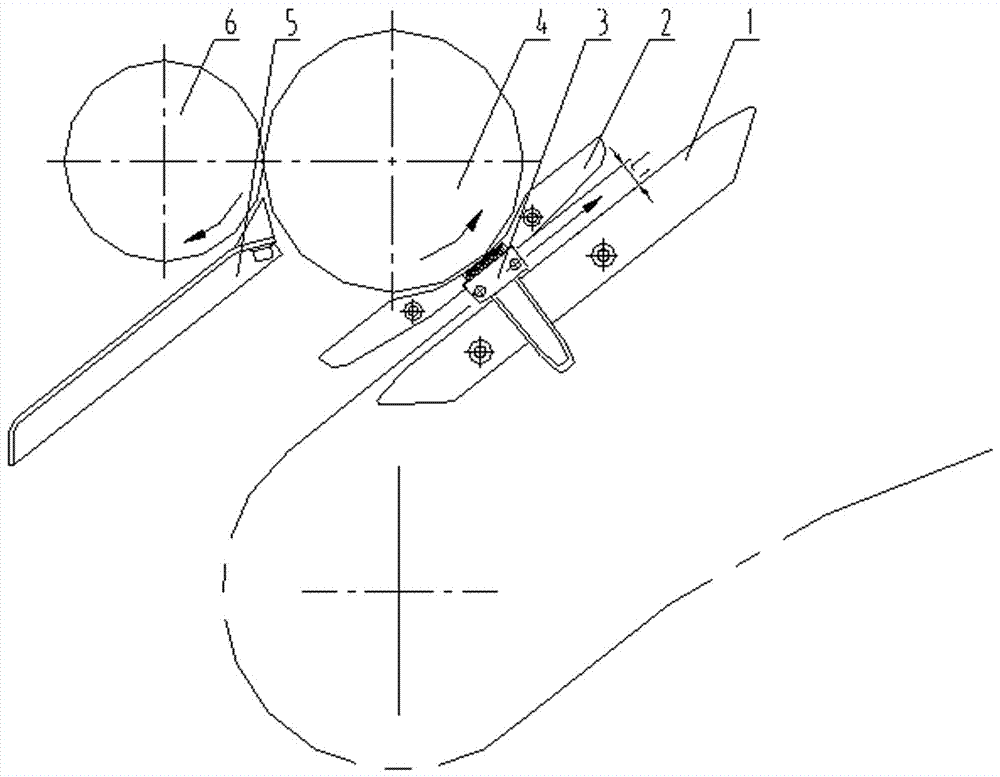

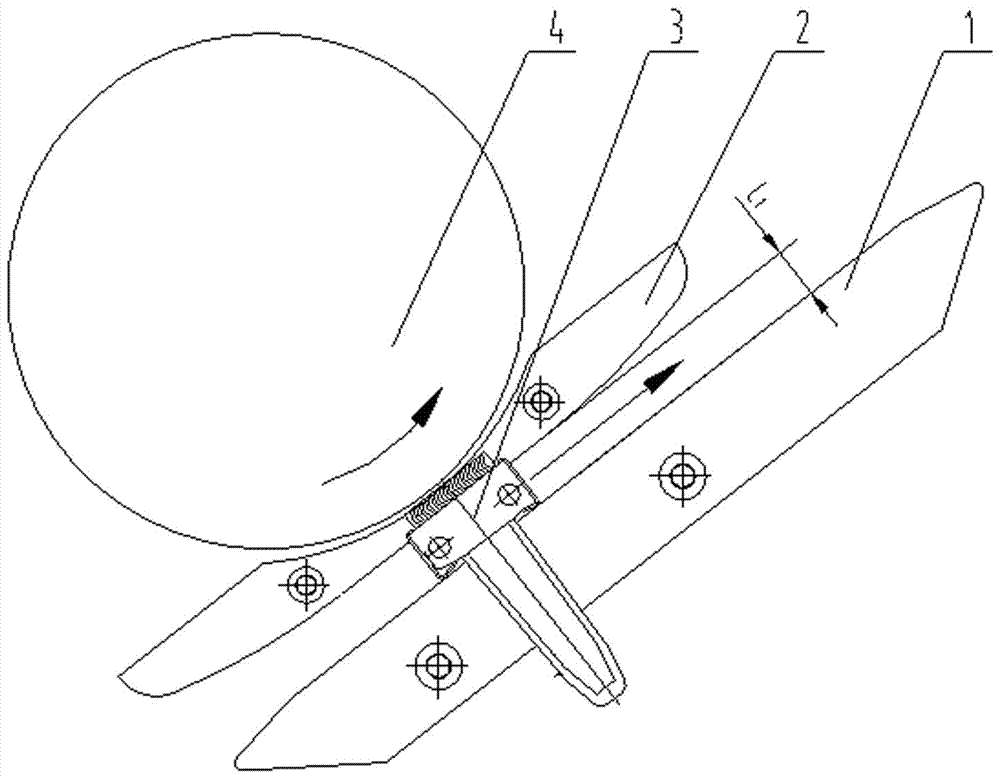

[0017] The present invention is further described below in conjunction with embodiment (accompanying drawing):

[0018] like Figure 4 , Figure 5 As shown, the movable cover plate supporting structure of the present invention includes a supporting block 1, and the supporting block 1 passes through a bolt 10, a spring 11, a gasket 8, a stop nut, and a tightening nut that are sequentially set on the bolt from top to bottom. The solid nut is connected with the bracket 7, the bolt piercing hole processed on the supporting block 1 is a stepped hole whose upper and lower end apertures are larger than the middle section aperture, and the spring 11 is located in the lower end cavity of the stepped hole; The aperture of the upper hole of the stepped hole is greater than the maximum outer diameter of the upper end cap of the bolt 10, and the depth is greater than the thickness of the upper end cap of the bolt 10; the cross section of the bracket 7 is an L-shaped structure, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com