A limit device for a rotary shaft

A technology of limit device and rotary shaft, which is applied in metal processing and other directions, can solve the problems of increasing the size and complexity of the mechanism, increasing the size of the end-execution structure, etc., so as to improve the universality and expandability, save space, and make the limit reliable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

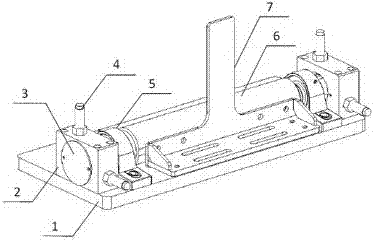

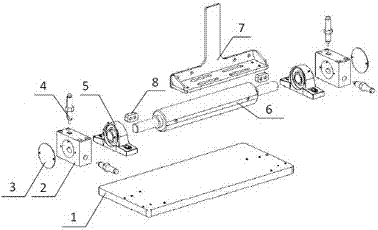

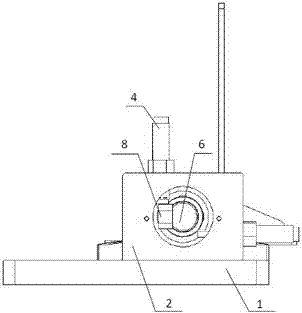

[0013] Attached below figure 1 , attached figure 2 , attached image 3 The present invention is further analyzed.

[0014] A rotary shaft 6 passes through two bearings with seats 5, the bearings with seats 5 are fixed on the base plate 1, and the two limit seats 2 are fixed on the base plate 1, and the cavities on the two limit seats 2 are the same as those of the rotary shaft 6. Shaft arrangement. Two hydraulic buffers 4 are installed on each limit seat 2, and a sealing plate 3 is installed on the end surface of the limit seat 2, which is used to block the end hole of the limit block after installation and debugging, so as to ensure the Safety protection for moving parts. An end effector 7 is fixed on the rotary shaft 6 , a plane is machined on both ends of the rotary shaft 6 and a limit block 8 is installed on the plane. The limit block 8 can be made into any shape according to the actual needs, so as to realize the arbitrary setting of the angle of 0-360°, the limit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com