Oscillation type loosening plant dyed fiber carding mechanism

A vegetable dyeing and oscillating technology, applied in the field of carding systems, can solve the problems of incapable of high-quality opening and carding of vegetable dye fibers, and achieve the effect of improving opening effect, good opening effect and preventing fiber clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the drawings.

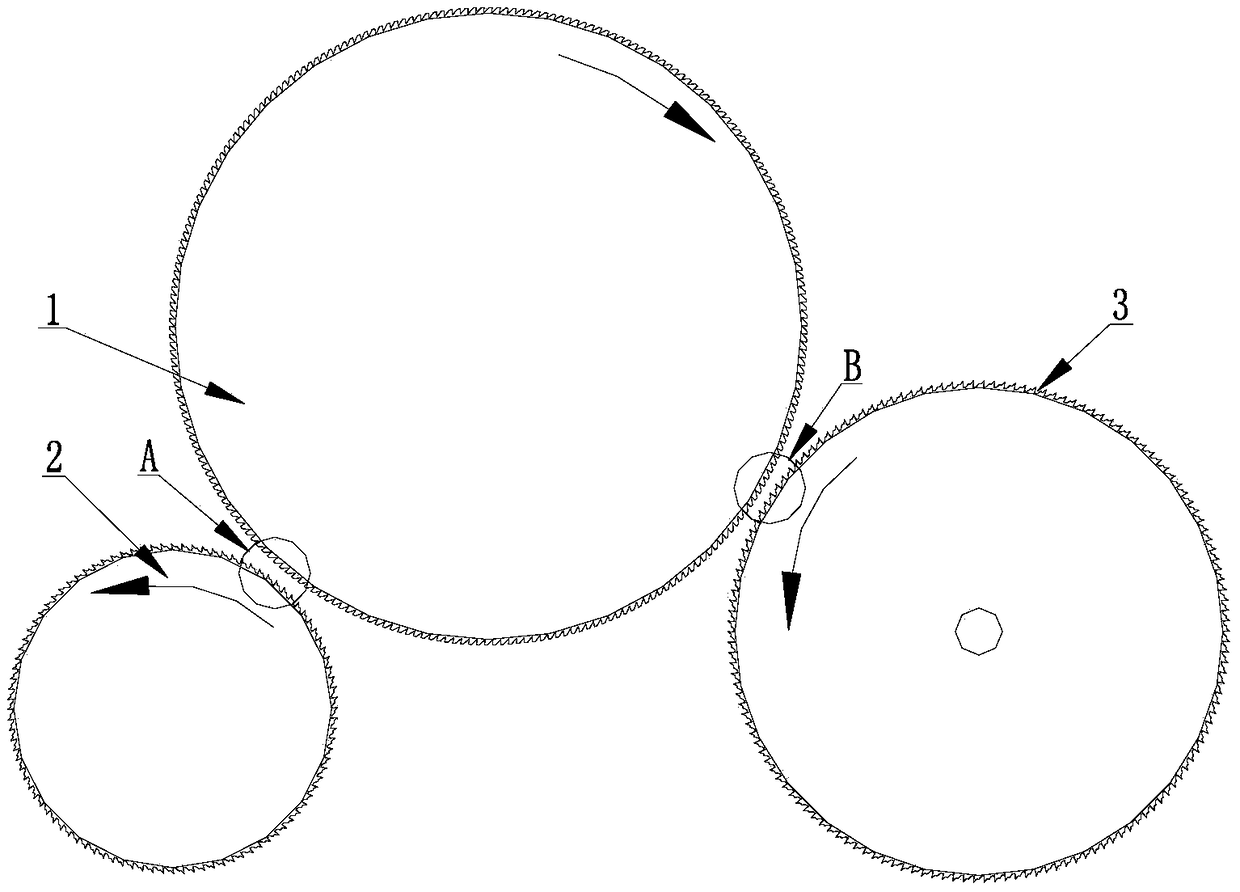

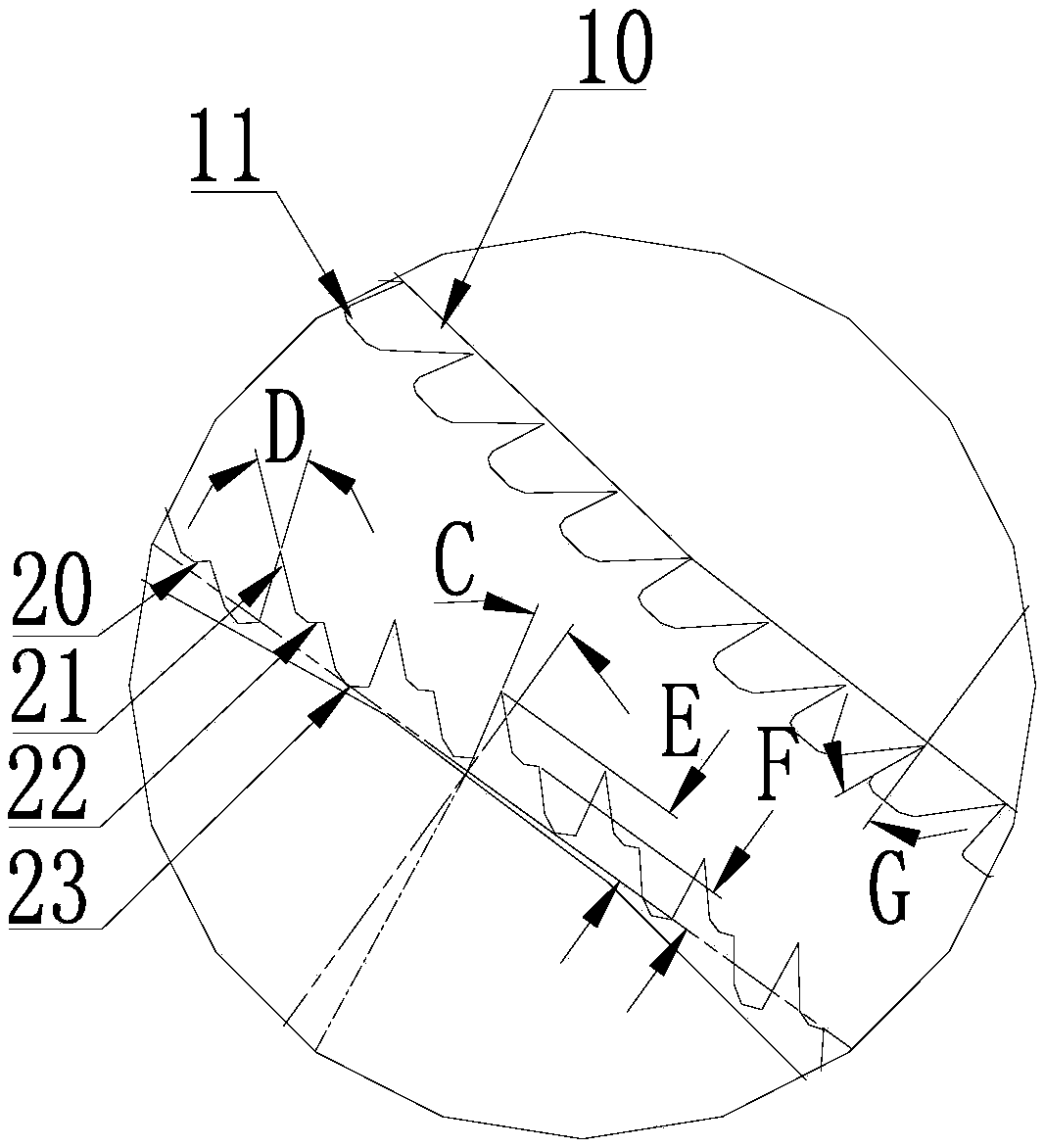

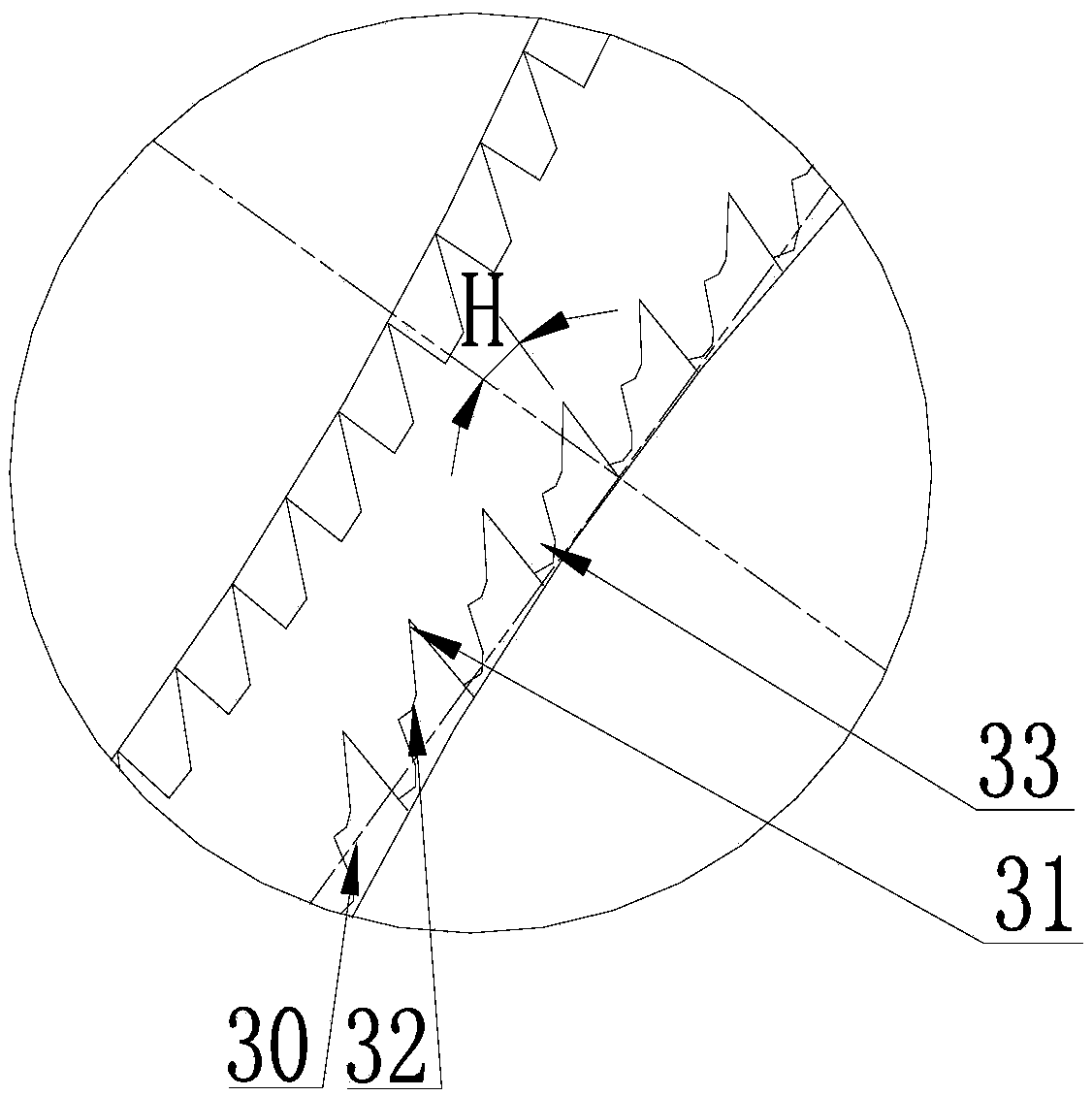

[0026] Such as Figure 1-3 As shown, an oscillating carding mechanism for opening plant dyed fibers includes a licker roller 2, a cylinder 1, and a doffer 3. The licker roller 2 is wound with a plurality of licker roller needle belts 20 in the front and rear direction or axially along the surface of the licker roller. The surface of the licker roller needle belt 20 is provided with opening needle teeth. The opening needle teeth are in a stepped double-peak shape. The peak 21 of the opening pin is sharp angle, which is good for the licker roller to penetrate the fiber and whiskers effectively and improve the opening effect. The low peak 22 of the opening pin is located at the middle step of the opening pin, and the low peak 22 of the opening pin The tip is an obtuse angle, which not only reduces the density of the piercing needles and reduces the damage to the fiber by the opening, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com