Novel fully-fixed cover board carding machine

A technology of fixed flat and carding machine, which is applied to the textile of carding machine, fully fixed flat carding machine, the manufacture of carding machine, and textile field, which can solve the problem that there are not many research literatures on fully fixed flat carding machine To achieve the effect of strengthening the ability of removing impurities and short fibers, ensuring the quality of carding, and enhancing the ability of carding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

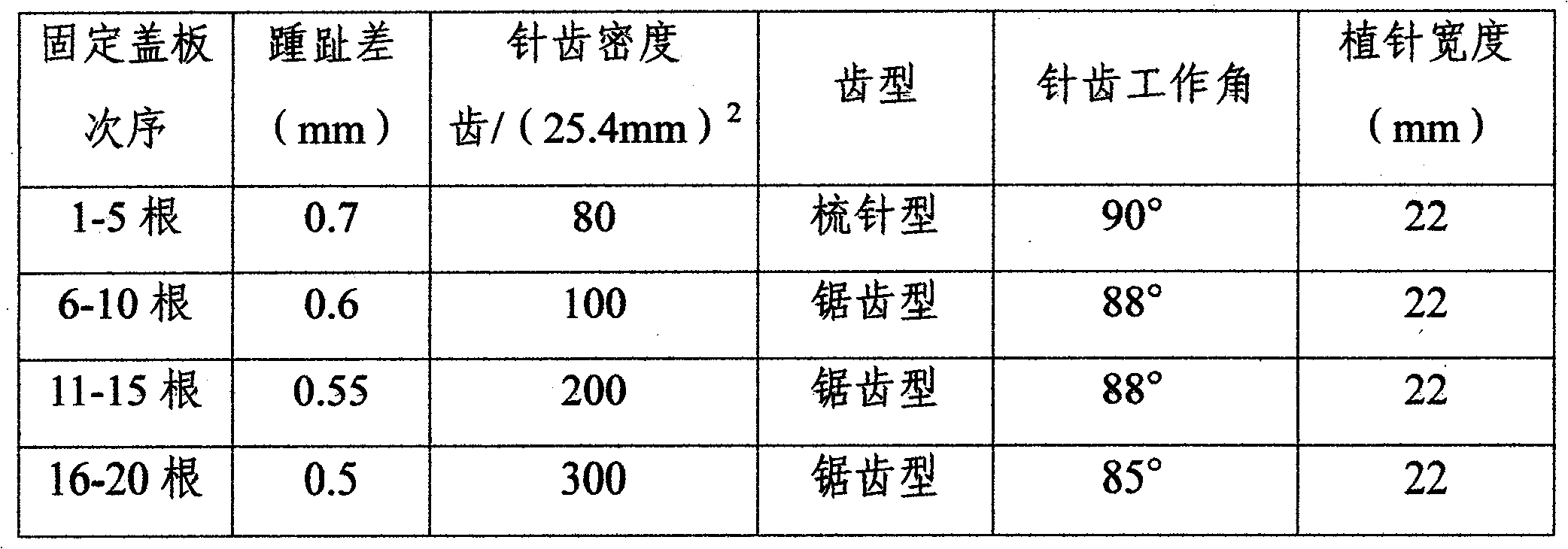

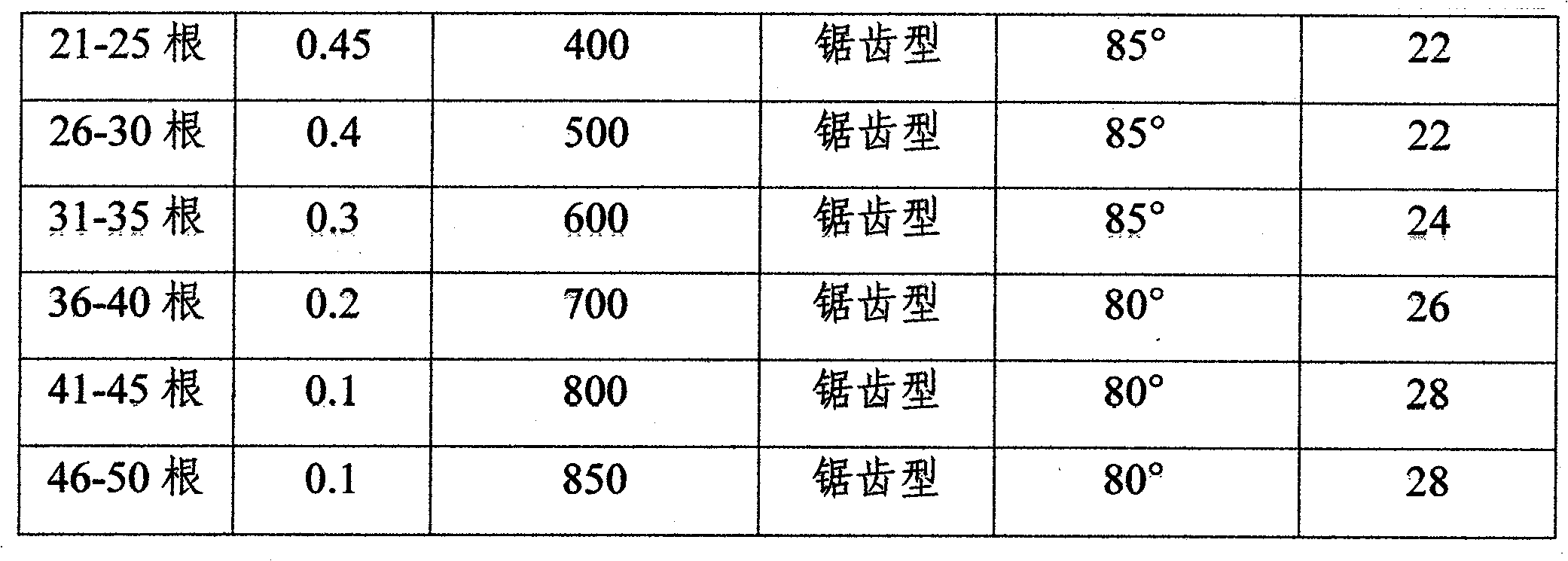

[0018] Table 1 Variation of fixed cover plate parameters in different areas of cylinder

[0019]

[0020]

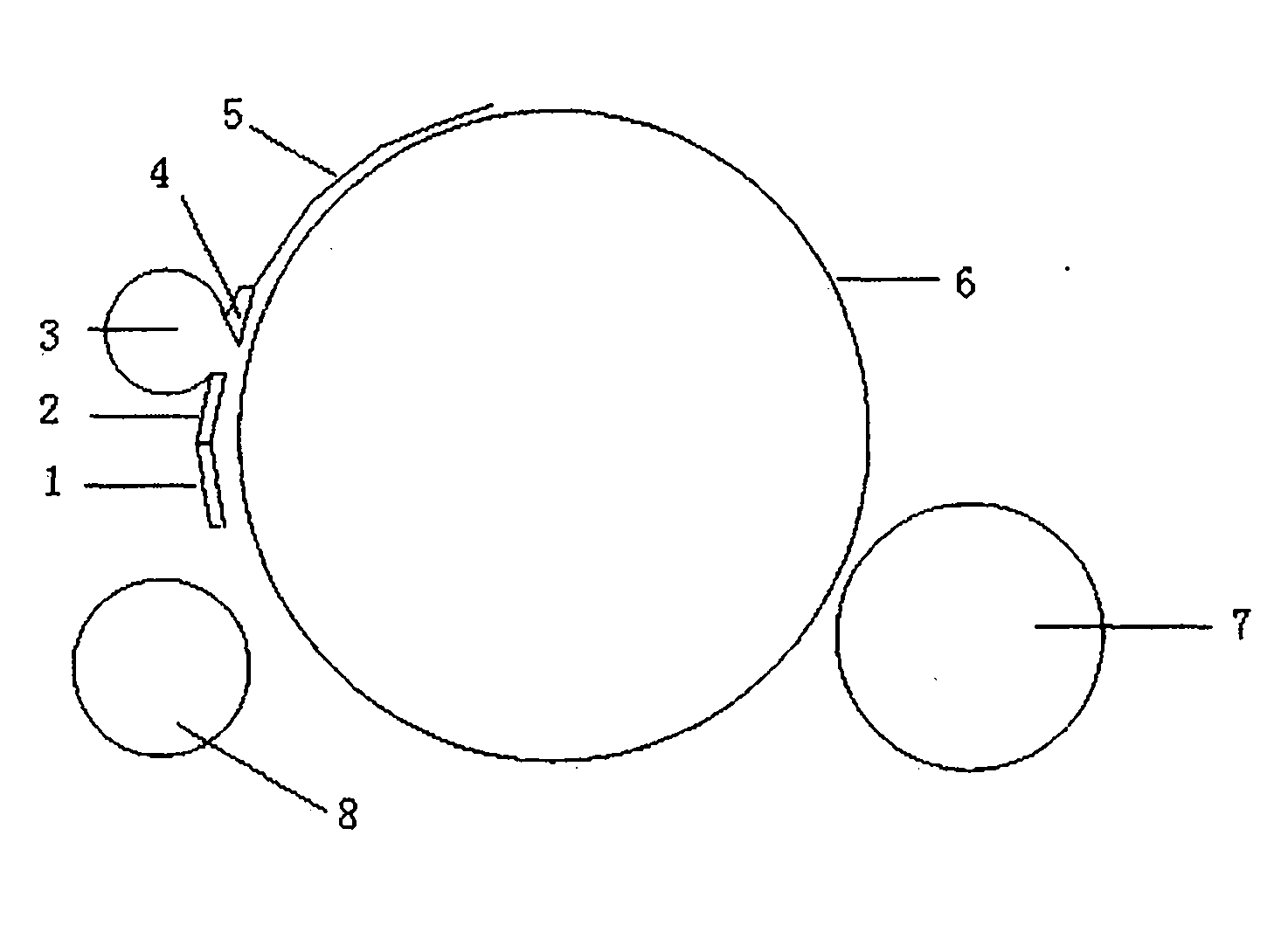

[0021] Fig. 1 is a schematic diagram of the design of this patent. Taking this picture as an example, according to the specific output of the carding machine and the different processing raw materials, it is also possible to produce the second and third structural forms with different heel to toe differences, fixed cover density, needle tooth working angle and needle planting width. , but the changing trend remains the same. At the same time, the design form of the new full-fixed flat carding machine with more schemes can be derived by combining changes in different aspects.

[0022] After the implementation of the patent of the present invention is completed, an assessment test has been carried out, and the expected good effect has been obtained.

[0023]The above is only a preferred embodiment of the patent of the present invention, and does not limit the paten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com