Metal card clothing for carding superfine fibers

A technology of ultra-fine fiber and metal card clothing, which is used in fiber processing, textile and paper making, deburring devices, etc., can solve the problems of easily damaged fibers, weak single-tooth body strength, difficult processing, etc. Large contact area and enhanced carding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

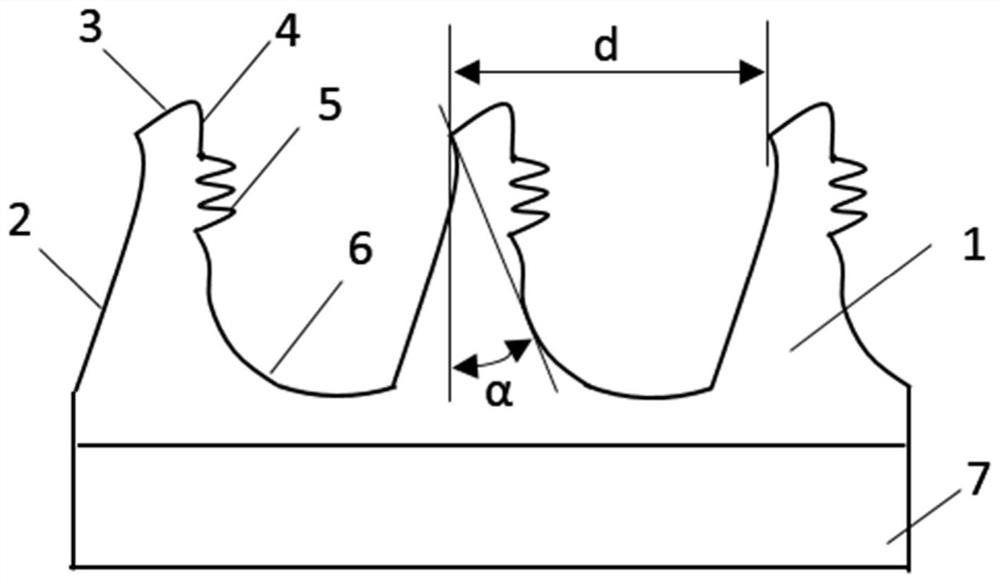

[0033] In this embodiment, several needle teeth 1 are protrudingly arranged along the strip-shaped base, and the outer surface of each needle tooth 1 can be divided into a first working surface 2, an oblique tooth tip surface 3, a second working surface 4, and a stepped oblique shape. The edge tooth surface 5 and the arc surface 6, the first working surface 2 and the oblique tooth tip surface 3 are connected by a smooth transition surface, the angle of the oblique tooth surface 3 is 30°, and the stepped oblique tooth surface 5 is Arranged at equal intervals, the angle is 25°, the spacing is 0.3mm, and the protruding length is 0.5mm. The distance d is 0.6mm, the fiber diameter is 1μm, and the length is 35mm. The base 7 is made of high-strength alloy steel, which adopts oxidation quenching and annealing processing technology. The surface of the pin tooth 1 is treated with tungsten carbide alloy coating to improve the wear resistance of the card clothing. .

Embodiment 2

[0035] A plurality of needle teeth 1 are protrudingly arranged along the strip-shaped base, and the outer surface of each needle tooth 1 can be divided into a first working surface 2, an oblique tooth tip surface 3, a second working surface 4, and a stepped oblique edge. The tooth surface 5 and the arc surface 6 are connected by a smooth transition between the first working surface 2 and the oblique tooth surface 3. The angle of the oblique tooth surface 3 is 32°, and the stepped oblique tooth surface 5 is equal to Arranged at intervals, the angle is 30°, the interval is 0.5mm, and the protruding length is 0.7mm. d is 0.8mm, the fiber diameter is 25μm, and the length is 40mm. The base part 7 is made of high-strength alloy steel material, and the oxidation quenching and annealing process is adopted. The surface of the tooth 1 is treated with tungsten carbide alloy coating to improve the wear resistance of the card clothing.

Embodiment 3

[0037] A plurality of needle teeth 1 are protrudingly arranged along the strip-shaped base, and the outer surface of each needle tooth 1 can be divided into a first working surface 2, an oblique tooth tip surface 3, a second working surface 4, and a stepped oblique edge. The tooth surface 5 and the arc surface 6, the first working surface 2 and the oblique tooth surface 3 are connected by a smooth transition surface, the angle of the oblique tooth surface 3 is 35°, and the stepped oblique tooth surface 5 is equal to Arranged at intervals, the angle is 35°, the interval is 0.7mm, and the protruding length is 0.9mm. d is 1.2mm, the fiber diameter is 40μm, and the length is 48mm. The base part 7 is made of high-strength alloy steel material, which adopts oxidation quenching and annealing processing technology. The surface of the tooth 1 is treated with tungsten carbide alloy coating to improve the wear resistance of the card clothing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com