Double-throwing-coarse cashmere carding machine

A carding machine and roughing technology, which is applied in the deburring device, textile and papermaking, fiber treatment, etc., can solve the problems of low efficiency of fuzz-free extraction, unsatisfactory effect of roughing and impurity removal, etc., and achieve enhanced roughing effect , The effect of reducing the lint content rate and improving the coarse throwing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

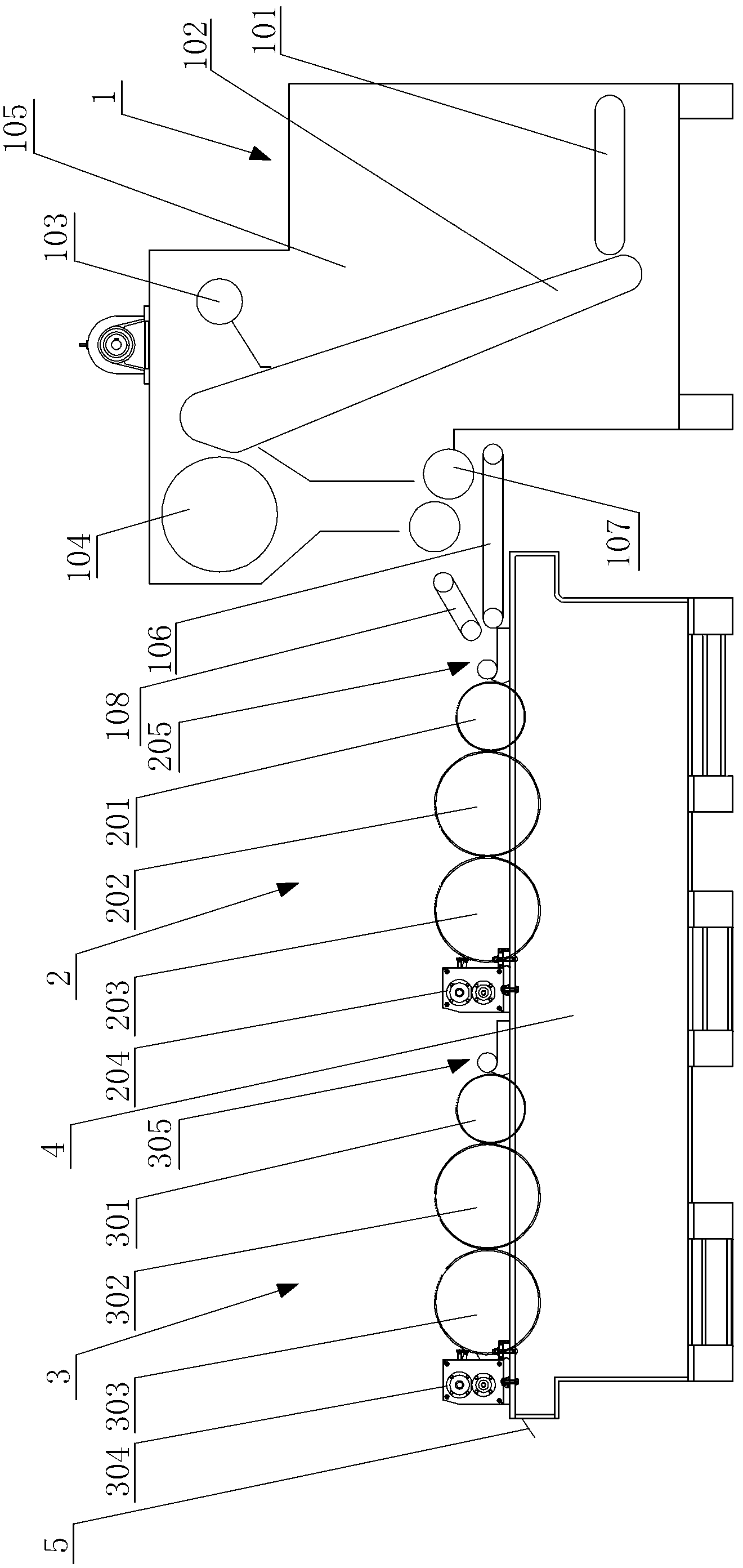

[0019] combine figure 1 As shown, the double-throwing coarse cashmere carding machine includes a feeding mechanism 1 and a carding mechanism. The carding mechanism is composed of front and rear two-stage carding units 2 and 3, and the rear-stage carding unit is located directly behind the front-stage carding unit. , The feeding mechanism, the pre-stage carding unit and the rear-stage carding unit are connected in sequence. The front-stage carding unit and the rear-stage carding unit have the same internal structure, and the front-stage carding unit and the rear-stage carding unit are arranged on the same frame body 4. The floor space of the frame body is the same as that of the existing cashmere carding machine. The floor area of the middle carding mechanism is the same, on the basis of the original floor area, the transformation from the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com